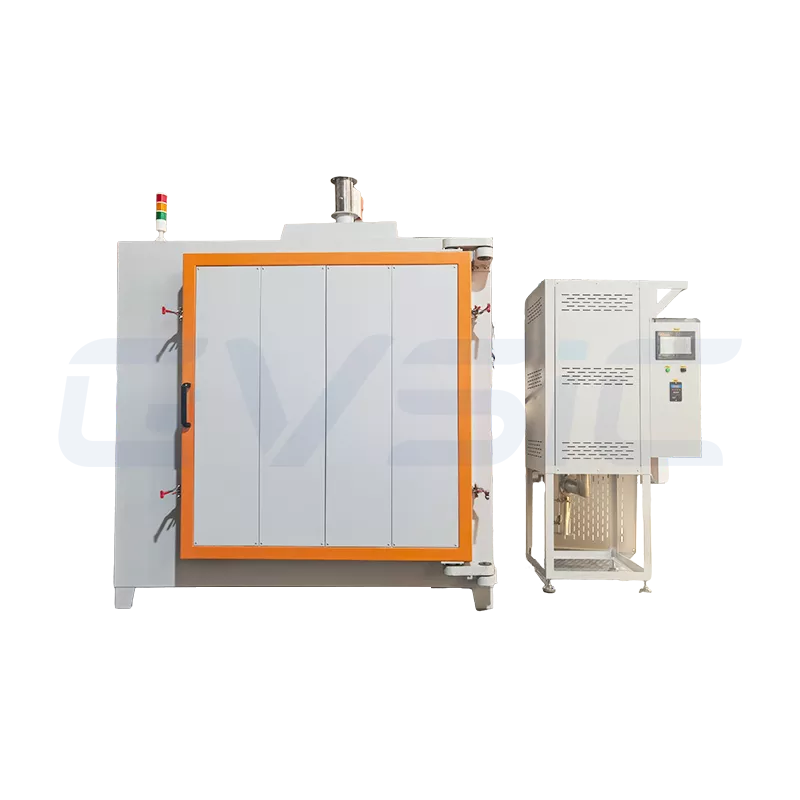

Hot Air Circulation Debinding Furnace

Hot Air Debinding Furnace

The CVSIC Hot Air Circulation Debinding Furnace is designed for the ceramic, aerospace, and scientific research industries, with a maximum temperature of 650°C. It has intelligent temperature control, VOC exhaust gas cracking, and an efficient hot air circulation system. Supports large-capacity degreasing, energy-efficient, and environmentally friendly, offering customized solutions and global wholesale services.

- Name: Hot Air Circulation Debinding Furnace

- Furnace Chamber: Stainless Steel Chamber

- Heating Element: Resistance Wire

- Maximum Temperature: 650°C

- Operating Temperature: 600°C

- Vacuum Level: Non-Vacuum

- Available Atmosphere: Inert Atmosphere (N₂, CO₂, Ar₂, etc.)

- Application Processes: Sintering, Debinding Sintering, Heat Treatment

The CVSIC Hot Air Circulation Debinding Furnace is a high-efficiency thermal processing equipment integrating an air preheating unit, degreasing furnace, and VOC exhaust gas cracking furnace, specifically designed for the ceramic, aerospace, new materials, medical, and research industries. Featuring a 310S stainless steel furnace chamber and resistance wire heating elements, it achieves a maximum temperature of 650°C (operating temperature 600°C) and supports inert atmosphere environments (N₂, CO₂, Ar), ensuring efficient degreasing and environmentally friendly emissions.

The furnace achieves a uniform temperature field with a temperature difference of ±5°C through its intelligent temperature control system, high-speed turbulent airflow fan, and three-sided heating design. Equipped with an air preheating device (maximum 400°C) and a VOC exhaust gas cracking furnace (high-temperature zone ensures complete cracking of exhaust gas), significantly improving degreasing efficiency and environmental performance. The equipment supports large-capacity loading (maximum 800×800×1000mm), suitable for laboratory and small-batch production needs.

CVSIC Hot Air Circulation Debinding Furnace Application

- Ceramic industry: degreasing and pre-sintering processes for ceramic materials such as alumina and zirconia.

- Aerospace: degreasing treatment of high-precision composite materials and ceramic components.

- Research and laboratories: degreasing experiments on new materials (such as nanomaterials and composite materials).

- Medical industry: Thermal treatment of medical ceramics and implant materials.

- New material development: Degreasing processes for high-performance materials and 3D-printed parts.

- Heat treatment: Supports sintering and heat treatment applications for lightweight materials.

This furnace model offers an ideal solution for customers requiring efficient, environmentally friendly, and precise degreasing solutions, particularly suited for laboratory and small-batch production.

Hot Air Debinding Furnace Customization Services

CVSIC offers comprehensive customization services to ensure seamless integration with your production and R&D requirements:

- Chamber dimensions: Customize heating zone dimensions based on production scale to accommodate varying load capacities.

- Temperature and Atmosphere: Customized temperature configurations within the 650°C range and inert atmosphere systems (N₂, CO₂, Ar) are available.

- Exhaust Gas Treatment: Customized VOC cracking systems or dedicated degreasing tanks are available to optimize treatment efficiency in high exhaust gas volume scenarios.

- Control System: Customized touchscreen interfaces and PLC programs are provided, supporting data monitoring and remote control.

Optional Accessories:

- Specialized degreasing tank: Designed for high exhaust gas volume materials such as tar and wax, enhancing cracking efficiency.

- Air preheating device: Enhances preheated air temperature and flow rate to accommodate specific processes.

- RS232/RS485 software: Supports data logging and remote monitoring.

- Global Support: Provides installation guidance, operational training, and maintenance services to ensure the stable, long-term operation of the equipment.

Contact CVSIC for customized Hot Air Circulation Debinding Furnace solutions tailored to your industry, supporting global wholesale and custom orders.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Hot Air Circulation Debinding Furnace

Debinding and Pre-Sintering Integrated Furnace

- Name: Debinding and Pre-Sintering Integrated Furnace

- Furnace Chamber: Ceramic Fiber

- Heating Elements: Resistance Wire, SiC Heating Elements

- Maximum Temperature: 650°C, 1200°C

- Voltage: 380V

- Vacuum System: None

- Available Atmosphere: Inert atmosphere (N₂, CO₂, Ar₂, etc.)

- Process Applications: Sintering, Brazing, Debinding Sintering, Heat Treatment, Annealing

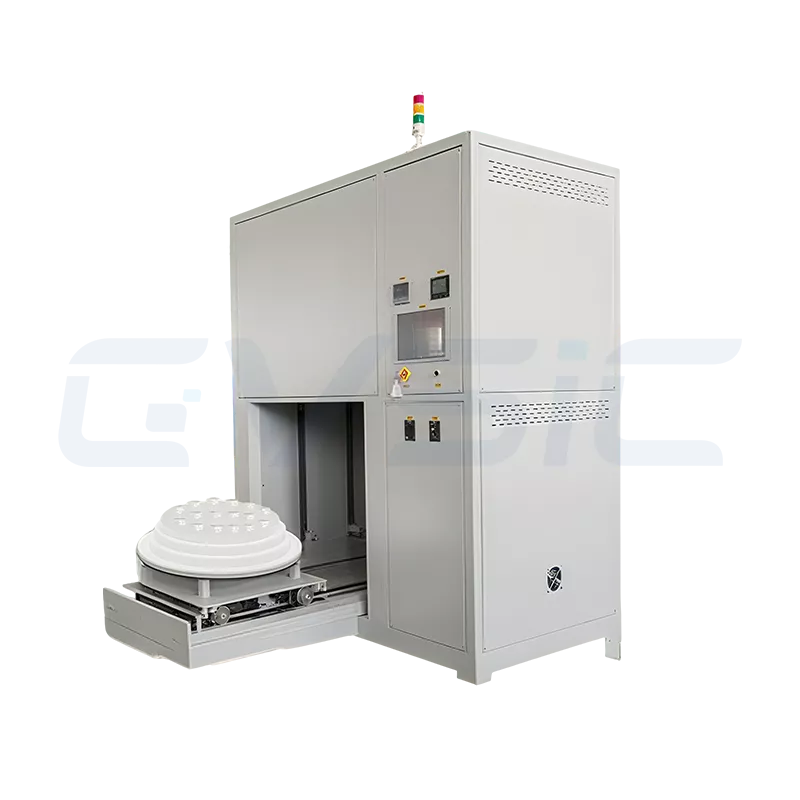

Lifting Atmosphere Sintering Furnace

- Name: Atmosphere debinding and sintering furnace

- Furnace chamber: Ceramic fiber

- Heating elements: MoSi2 heating elements

- Maximum temperature: 1700°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Available Atmosphere: Inert Gas (N₂, CO₂, Ar₂)

- Applications: Degreasing Sintering, Heat Treatment

Bottom Loading Debinding and Sintering Furnace

- Name: Degreasing and Sintering Furnace

- Furnace Lining: Ceramic Fiber

- Heating Elements: MoSi2 Heating Elements

- Maximum Temperature: 1750°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Process Applications: Degreasing Sintering, Heat Treatment

- Brand: CVSIC

Hydrogen Furnace

- Name: Hydrogen Sintering Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With maximum working temperature 1600℃

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support