Box-Type, Tube-Type, and External-Heat Atmosphere Furnaces Compared: Which One Suits Your Needs?

As an engineer, I know the importance of choosing the right atmosphere furnace. Box, tube, and external-heating furnaces…

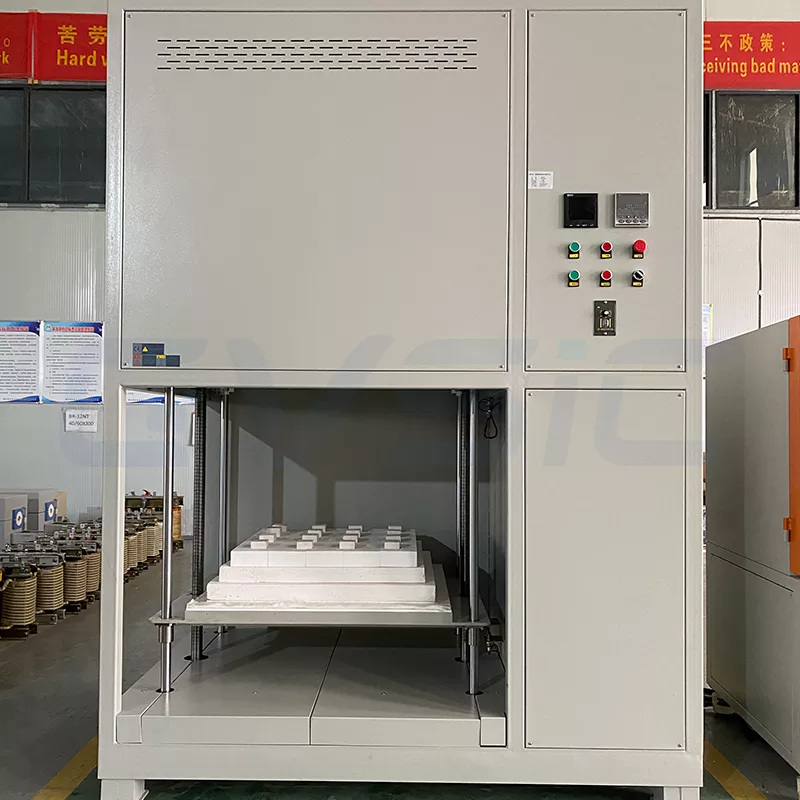

The Hydrogen Sintering Furnace is specifically designed for metal, ceramic, and semiconductor materials, with a maximum temperature of 1600°C. It supports hydrogen degreasing and reduction atmosphere sintering, and is equipped with a wet hydrogen module, an explosion-proof system, and VOC exhaust gas treatment. It suits global wholesale and R&D needs by offering precise control and customized solutions. Contact us now!

The CVSIC Hydrogen Sintering Furnace is designed for high-purity, high-efficiency sintering processes under hydrogen or reducing atmospheres. This furnace is ideal for processing metal powders, ceramic parts, and special alloys where oxidation must be strictly avoided. Engineered with advanced insulation, atmosphere control, and safety systems, it delivers uniform heating and consistent product quality.

The Hydrogen Sintering Furnace is widely used in:

CVSIC offers comprehensive customization services to ensure seamless integration of equipment with your production and R&D needs:

Looking for a safe, efficient, and customizable hydrogen furnace solution? Contact CVSIC for a customized system that precisely matches your specific processing needs.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

As an engineer, I know the importance of choosing the right atmosphere furnace. Box, tube, and external-heating furnaces…

With over 20 years of experience in high-temperature industrial applications, I understand the crucial role protective gases play…

Having worked in the high-temperature industrial sector for many years, I fully understand how heavily powder metallurgy (PM)…

Vacuum vs. Atmosphere Tube Furnaces: Selecting the Optimal Equipment for Your Experiments Sample oxidation or contamination in high-temperature…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support