Dental Furnaces: A Comprehensive Guide from Sintering Furnaces to Porcelain Furnaces

In dental clinics and laboratories, dental furnaces are essential pieces of equipment. Whether producing realistic all-ceramic crowns or…

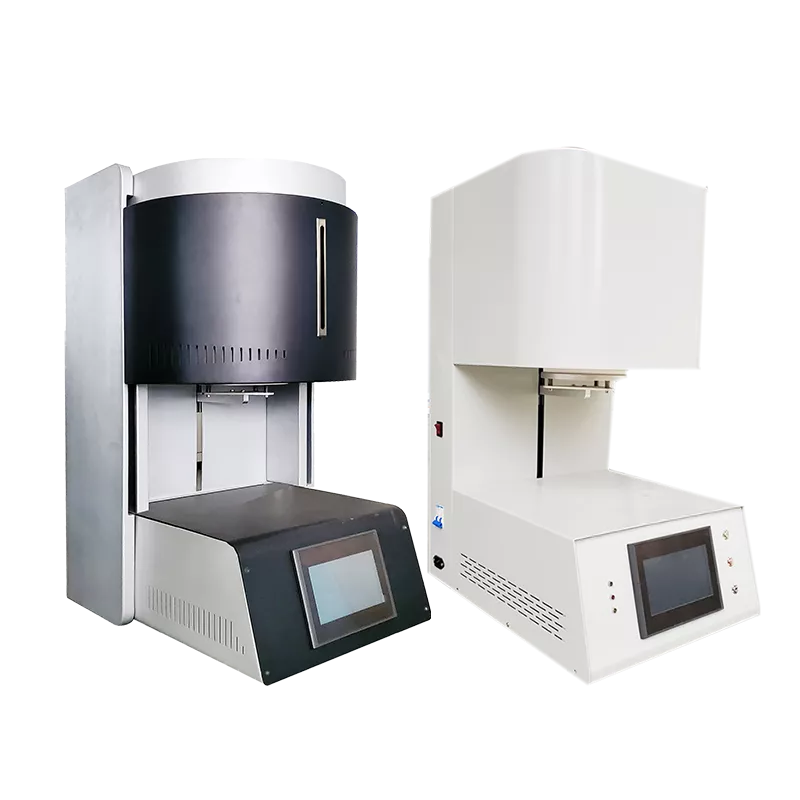

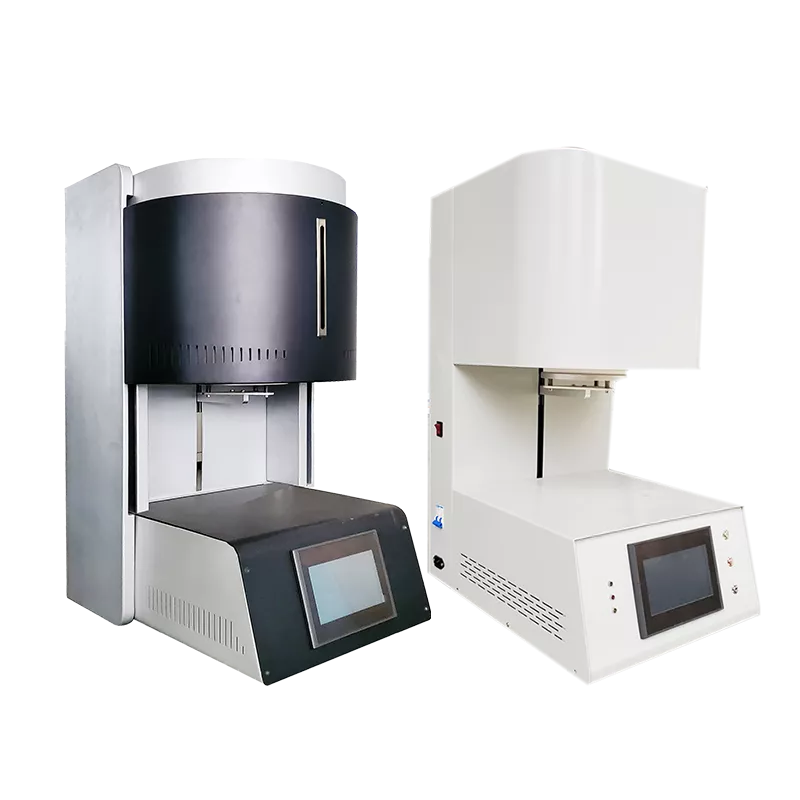

The Lift-Type Dental Zirconia Sintering Furnace features an electric lift platform, uniform heating with silicon molybdenum rods, a maximum temperature of 1700°C, ±1°C precise temperature control, and low energy consumption at 2kW. It is designed explicitly for zirconia sintering in dental laboratories and offers high efficiency and intelligence.

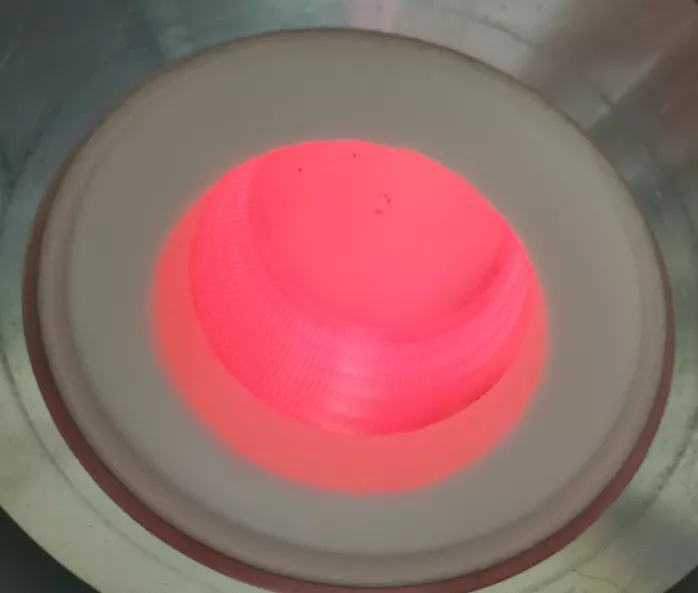

The CVSIC Lift-Type Sintering Furnace is engineered explicitly for dental laboratories and advanced ceramic processing. Its electric lift platform allows safe, precise, and rapid crucible positioning. A polycrystalline alumina fiber chamber combined with ring-shaped MoSi2 heating rods ensures outstanding thermal uniformity and stability.

With a maximum temperature of 1700°C (continuous operation at 1600°C), ±1°C accuracy, and a 2kW low-power design, it strikes a balance between efficiency, cost-effectiveness, and precision. A 7-inch high-definition touchscreen with 50-segment programmable control and 30 storage slots provides smart, flexible operation for zirconia sintering, structural ceramics, and polymer ceramics.

Upgrade your dental laboratory with the CVSIC Lift-Type Sintering Furnace – an efficient, precise, and energy-saving solution. Contact us today to receive a quotation, explore customization options, or discuss wholesale cooperation details.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

In dental clinics and laboratories, dental furnaces are essential pieces of equipment. Whether producing realistic all-ceramic crowns or…

Introduction: Temperature and Materials—The Fundamental Principles of Sintering Furnaces The creation of high-quality restorations is significantly influenced by…

In dental labs, furnaces are essential tools for creating restorations, with sintering and porcelain furnaces being the two…

Introduction: Choosing the Ideal Sintering Furnace for Your Dental Laboratory As an engineer, I recognize how the appropriate…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support