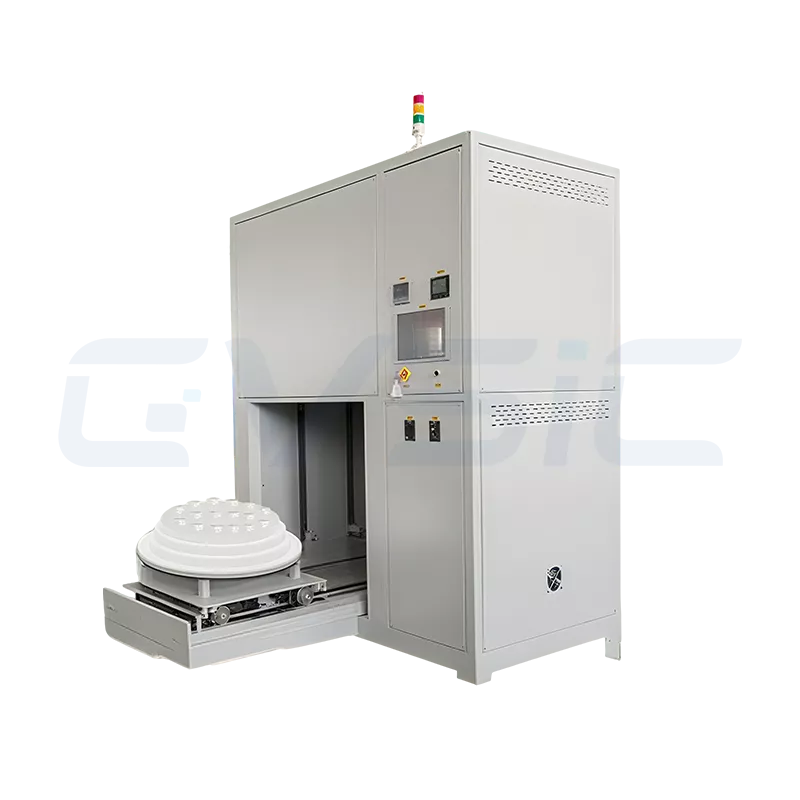

Lifting Atmosphere Sintering Furnace

Atmosphere debinding and sintering furnace

The CVSIC Lift-Bottom Atmosphere Sintering Furnace is specifically designed for the ceramic, electronic, and metallurgical industries, supporting an extensive capacity loading of 200-600 kg, with a maximum temperature of 1700°C, and compatible with atmospheres such as N2, Ar, and CO2. It is suitable for semi-continuous production, offering customized solutions and global wholesale services.

- Name: Atmosphere debinding and sintering furnace

- Furnace chamber: Ceramic fiber

- Heating elements: MoSi2 heating elements

- Maximum temperature: 1700°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Available Atmosphere: Inert Gas (N₂, CO₂, Ar₂)

- Applications: Degreasing Sintering, Heat Treatment

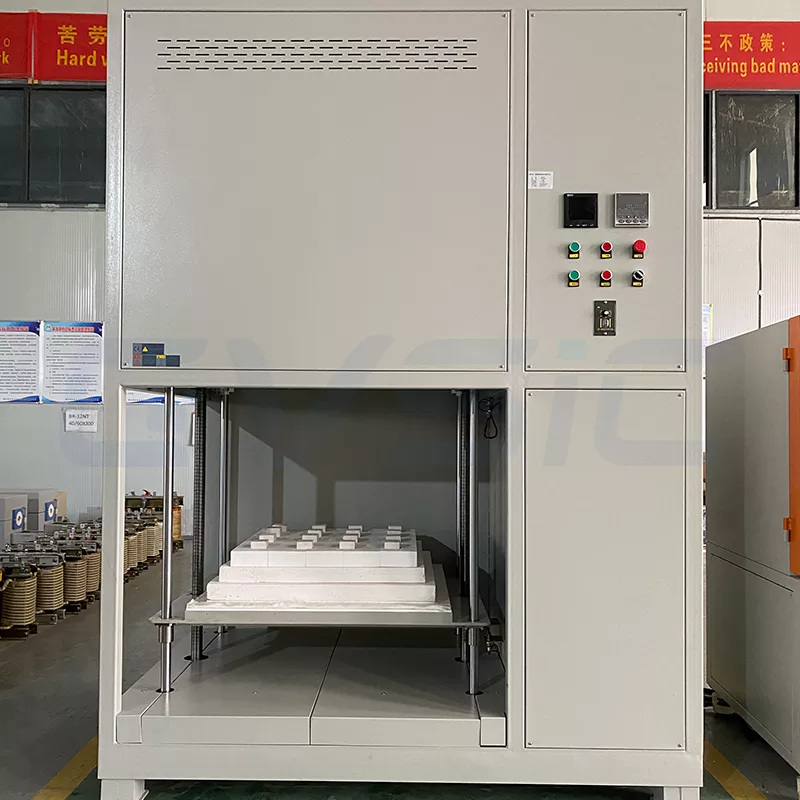

The CVSIC Atmosphere Sintering Furnace is a high-performance, multi-functional heat treatment device for the ceramic, electronics, metallurgy, chemical, and new materials development industries. The furnace features a lift-type structure with a cart and track system, capable of handling 200-600 kg loads, making it particularly suitable for semi-continuous production modes to ensure efficient production and convenient operation.

This furnace model offers three temperature configurations: 1200°C, 1400°C, and 1700°C, to meet the high-temperature processing requirements of various materials. It supports inert gas atmospheres (N₂, Ar, CO₂, He) and combustible gas atmospheres, featuring graphite heating fields and elements. The maximum operating temperature is 1600°C , with a vacuum level of up to 10 Pa, ensuring excellent thermal stability and process flexibility.

CVSIC Atmosphere Sintering Furnace Advantages

The CVSIC Lift-Bottom Atmosphere Sintering Furnace stands out with its advanced design and user-oriented features:

- Durable furnace chamber: Features a three-layer all-fiber lining combined with high-temperature mullite bottom bricks, offering excellent wear resistance and load-bearing performance, ensuring long-term stability at 1700°C.

- Precise temperature control system: Equipped with a Siemens PLC control system, a 10-inch touchscreen, and a Yudian temperature controller, providing intuitive operation, precise temperature control, and support for process parameter optimization.

- Reliable lifting system: Utilizes a lead screw drive for smooth lifting of the furnace chamber lid, with Schneider travel switches providing dual protection. The fully automatic material handling cart has Schneider limit switches and safety devices, enhancing safety and service life.

- Flexible Atmosphere Control: Supports inert gases such as nitrogen, argon, and helium, as well as flammable gases. Equipped with dual vacuum diaphragm valves, float flow meters, and digital/analog pressure gauges to ensure precise gas flow and pressure management.

- Large Capacity Design: Loading 200-600 kg capacity, meeting semi-continuous production requirements and improving efficiency.

- Energy-efficient and high-performance: Optimized insulation and heating element design reduce energy consumption while maintaining uniform temperature distribution.

CVSIC Atmosphere Sintering Furnace Application Scenarios

The CVSIC Lift-Bottom Atmosphere Sintering Furnace is widely used in the following industries for high-temperature processes:

- Ceramic industry: Used for structural and electronic ceramics’ sintering processes.

- Electronics industry: Supports heat treatment of semiconductor and photovoltaic materials.

- Metallurgy industry: Suitable for sintering and heat treatment of metal alloys and powder metallurgy components.

- Chemical industry: High-temperature reactions and catalyst production requiring precise atmosphere control.

- New materials research and development: Used for synthesizing and testing composite materials and nanomaterials.

- Debinding and sintering: Debinding and sintering processes for ceramic and metal injection molding (MIM).

This furnace type provides an ideal solution for manufacturers and research institutions requiring high throughput and reliable equipment.

Customization Services

CVSIC offers personalized customization services to ensure seamless integration with your production requirements:

- Chamber dimensions and capacity: Customize chamber dimensions and loading capacity based on production scale.

- Temperature range: Provide customized temperature configurations from 1200°C to 1700°C.

- Atmosphere System: Customize inert or combustible gas systems for specific processes.

- Control System: Provide customized PLC and Human-Machine Interface (HMI) for seamless integration with existing workflows.

- Heating Elements: Customize graphite or other heating elements based on application requirements.

- After-Sales Support: Offer global installation, training, and maintenance services to ensure long-term, reliable operation of the equipment.

Contact CVSIC for customized sintering furnace solutions tailored to your industry, supporting global wholesale and custom orders.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Lifting Atmosphere Sintering Furnace

Hot Air Circulation Debinding Furnace

- Name: Hot Air Circulation Debinding Furnace

- Furnace Chamber: Stainless Steel Chamber

- Heating Element: Resistance Wire

- Maximum Temperature: 650°C

- Operating Temperature: 600°C

- Vacuum Level: Non-Vacuum

- Available Atmosphere: Inert Atmosphere (N₂, CO₂, Ar₂, etc.)

- Application Processes: Sintering, Debinding Sintering, Heat Treatment

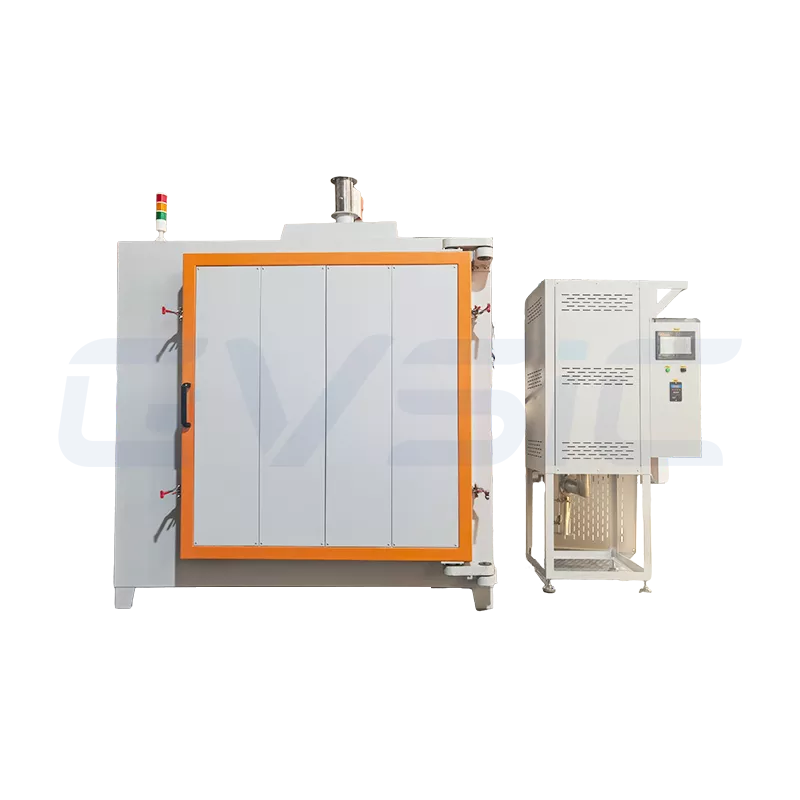

Debinding and Pre-Sintering Integrated Furnace

- Name: Debinding and Pre-Sintering Integrated Furnace

- Furnace Chamber: Ceramic Fiber

- Heating Elements: Resistance Wire, SiC Heating Elements

- Maximum Temperature: 650°C, 1200°C

- Voltage: 380V

- Vacuum System: None

- Available Atmosphere: Inert atmosphere (N₂, CO₂, Ar₂, etc.)

- Process Applications: Sintering, Brazing, Debinding Sintering, Heat Treatment, Annealing

Bottom Loading Debinding and Sintering Furnace

- Name: Degreasing and Sintering Furnace

- Furnace Lining: Ceramic Fiber

- Heating Elements: MoSi2 Heating Elements

- Maximum Temperature: 1750°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Process Applications: Degreasing Sintering, Heat Treatment

- Brand: CVSIC

Hydrogen Furnace

- Name: Hydrogen Sintering Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With maximum working temperature 1600℃

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support