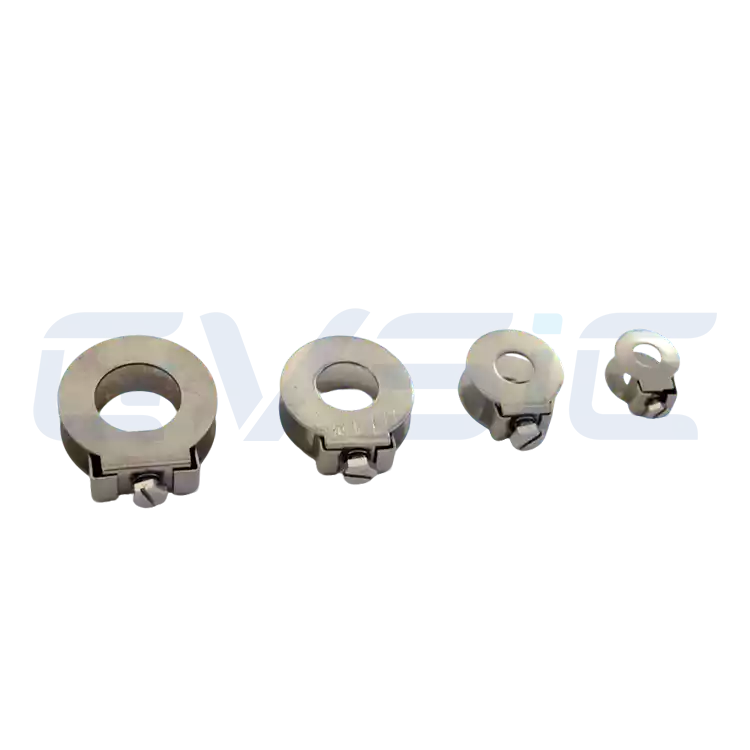

MoSi2 Heating Elements C Contact Clamp

Contact Strap/Holder/Clamp for Mosi2 Heating Element

CVSIC MoSi2 heating element C-type contact Clamp, made of high-quality stainless steel and spring steel, works with 6mm, 9mm, and 12mm sizes, handles high temps, resists corrosion, and is easy to set up. Offering global wholesale, customization, and OEM/ODM services. Contact us for free samples!

- Materials: High-quality stainless steel and heat-resistant spring steel

- Sizes: Diameters 6mm, 9mm, 12mm

- Thickness: 2mm

- Voltage: 110-480V

- Appearance: Silver, smooth

- Packaging: Carton

- Advantages: Corrosion-resistant, high-temperature resistant, rust-free, rapid heating, long lifespan, easy installation and maintenance

- Usage: Used with aluminum braid to secure MoSi2 cold-end aluminum coating for efficient conductivity

- Product Category: MoSi2 heating element accessory

- Inventory: In stock

- Origin: China

MoSi2 C Contact Clamp Description

CVSIC MoSi2 heating element C-type contact Clamp (also called C-type terminal Clamp or contact Clamp) is a specialized accessory for Molybdenum Disilicide (MoSi2) heating elements, crafted from high-quality stainless steel and heat-resistant spring steel with a 2mm thickness. Designed for 6mm, 9mm, and 12mm diameter MoSi2 elements, it pairs with aluminum braids to secure the element’s aluminum-coated cold end, ensuring efficient conductivity and stable connections. Great for high-temp furnaces, semiconductors, lithium batteries, and ceramics, it’s high-temperature and corrosion-resistant. The design makes setup and maintenance a breeze, resists rust for long-term use, supports fast heating, and ensures durability. In stock, packed in cartons, and made in China.

Ordering Information

When ordering MoSi2 heating element C-type contact Clamps, please provide the following parameters:

- MoSi2 Element Diameter: 6mm, 9mm, or 12mm

- Example: C-type contact Clamp for 6mm MoSi2 element, denoted as: C-Type Contact Clamp/6mm

Note: Custom specs are available to ensure a perfect fit with MoSi2 elements.

MoSi2 C Contact Clamp Connection Method

- Installation Position: The C-type contact Clamp secures the aluminum braid to the aluminum-coated cold end of the MoSi2 heating element, ensuring efficient conductivity.

- Connection Method:

- Place the aluminum braid on the MoSi2 cold end’s aluminum coating.

- Use the C-type spring Clamp to secure the aluminum braid tightly around the cold end.

- Verify the Clamp’s diameter marking (6mm, 9mm, 12mm) matches the MoSi2 element.

- Fasten with screws or the spring Clamp, ensuring connection end voltage <0.01V for solid electrical contact.

- After 2-3 hours of furnace operation, re-check Clamp tightness to address thermal relaxation.

- Note: Avoid over-compression during installation to prevent damage to the MoSi2 element. Ensure the aluminum braid makes complete contact with the aluminum coating on the cold end.

MoSi2 C Contact Clamp Application Fields

CVSIC MoSi2 heating element C-type contact Clamps are widely used in:

- High-Temperature Furnaces: Supports stable conductive connections in box furnaces, tunnel furnaces, and muffle furnaces.

- Electronic Semiconductors: Used for power connections in wafer sintering, diffusion furnaces, and encapsulation processes.

- Lithium Battery Materials: Supports electrical connections for high-temp processing of anode and cathode materials.

- Ceramics and Powder Metallurgy: Ensures reliability and stability in high-temp sintering processes.

- Laboratory Testing Equipment: Meets connection needs for high-temp experiments and material testing.

MoSi2 C Contact Clamp Product Advantages

- Corrosion and Rust Resistance: High-quality stainless steel and spring steel resist oxidation and corrosion, suitable for various atmospheres (e.g., O2, N2).

- Rapid Heating: Great at conducting electricity with connection end voltage <0.01V, supporting fast heating and lower energy use.

- Long Lifespan: Spring Clamp design ensures stable connections, minimizing thermal relaxation for extended use.

- Easy Installation and Maintenance: The C-type design, featuring aluminum braids, simplifies setup and reduces maintenance costs.

- Precise Compatibility: Fits 6mm, 9mm, and 12mm diameter MoSi2 elements, with diameter markings for accurate matching.

- Stock Availability: Standard specifications ship within 2-3 days; custom specifications are delivered within 7-30 days.

- Global Service: ISO-certified factory offers free samples with no minimum order quantity.

MoSi2 C Contact Clamp Installation Method

To ensure the performance and safety of MoSi2 heating element C-type contact Clamps, follow these steps:

- Inspect Components: Confirm the C-type contact Clamp is undamaged and verify diameter markings (6mm, 9mm, 12mm) match the MoSi2 element.

- Secure Aluminum Braid: Place the aluminum braid on the MoSi2 cold end’s aluminum coating, using the C-type spring Clamp to compress and secure it, fastening it with screws or the spring Clamp.

- Check Stability: Ensure the Clamp is neither loose nor over-compressed to prevent damage to the MoSi2 element.

- Power Connection: Connect the aluminum braid to the power source, ensuring good contact and connection end voltage <0.01V.

- Maintenance Check: After 2-3 hours of furnace operation, re-check Clamp and screw tightness to prevent thermal relaxation.

Note: Professionals should do the installation to avoid over-compression or lateral force; contact us for detailed guidance.

MoSi2 C Contact Clamp Design Recommendations

- Diameter Matching: Choose a C-type contact Clamp matching the MoSi2 element’s cold end diameter (6mm, 9mm, 12mm), verifying marked numbers.

- Installation Space: C-type Clamps are well-suited for tight spaces, paired with aluminum braids for efficient layout.

- Installation Force: Avoid over-compression to keep the Clamp secure without damaging the MoSi2 element.

- Temperature Control: Use an SCR voltage regulator (for precise current control) to extend the Clamp and element lifespan.

- Regular Maintenance: Check the Clamp and screw tightness after 2-3 hours of initial operation to prevent loosening or corrosion that may affect performance.

Customization Services

CVSIC offers flexible customization for MoSi2 heating element C-type contact Clamps:

- Size Customization: Tailored to MoSi2 element diameters (6mm, 9mm, 12mm).

- OEM/ODM Services: Support bulk wholesale, free samples, no minimum order quantity, and delivery in 7-30 days.

- Special Coatings: Offer oxidation- or corrosion-resistant coatings for better high-temp performance.

- Technical Support: Provide expert guidance and thermal field simulation from selection to setup.

CVSIC is dedicated to providing top-notch MoSi2 C-type contact Clamps to optimize connection performance in high-temp furnaces, electronics, lithium batteries, and more. Contact us for product quotes and customization services or to request free samples that can help enhance your heating efficiency.MoSi2 C Contact Clamp Description

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To MoSi2 Heating Elements C Contact Clamp

MoSi2 Heating Element two Shank Holders

- Materials: Insulating ceramic (high-density alumina ceramic) and stainless steel (heat-resistant steel)

- Components: Stainless steel angle brackets, hex nuts, hex bolts, two insulating ceramic blocks

- Diameters: 3/6mm, 4/9mm, 6/12mm, 9/18mm, 12/24mm

- Appearance: Silver stainless steel clips, smooth white ceramic blocks, high-temperature resistant

- Voltage: 110-480V

- Packaging: Carton

- Advantages: Handles extreme heat, is corrosion-resistant, easy to install, supports thermal expansion and contraction

- Inventory: In stock

- Product Category: MoSi2 heating element accessory

- After-Sales Service: Global service center support

MoSi2 Heating Element Single Shank Holders

- Material: Stainless steel (heat-resistant steel)

- Components: Stainless steel angle brackets, hex nuts, hex bolts

- Diameter Compatibility: 3/6mm, 4/9mm, 6/12mm, 9/18mm, 12/24mm

- Appearance: Silver, smooth

- Voltage: 110-480V

- Packaging: Carton

- Applications: Suitable for various MoSi2 heating elements (U-type, W-type, L-type, straight)

- Advantages: High-temperature resistant, corrosion-resistant, flexible installation, easy operation

- Product Category: MoSi2 heating element accessory

- Origin: China

- Minimum Order Quantity: 10 pieces

- Inventory: In stock

- After-Sales Service: Global service center support

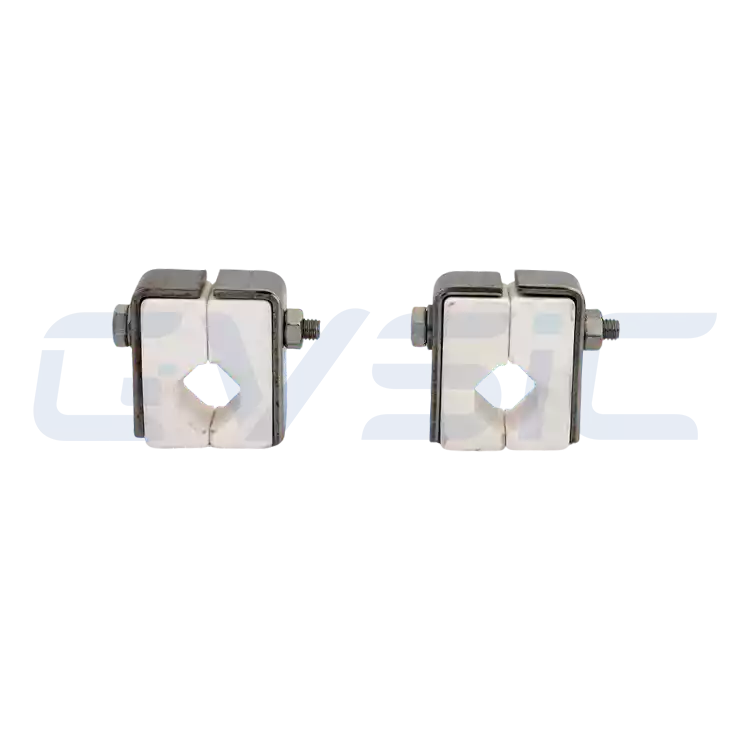

Mosi2 Heating Element Plate Holders

- Materials: High-density alumina ceramic (Al₂O₃) and corrosion-resistant stainless steel (heat-resistant steel)

- Components: Hex nuts, hex bolts, two insulating ceramic plates

- Diameters: 3/6mm, 4/9mm

- Temperature: Up to 1900℃

- Appearance: Silver stainless steel clip, smooth; white ceramic plates, high-temperature resistant

- Voltage: 110-480V

- Packaging: Carton

- Applications: Suitable for various Molybdenum Disilicide (MoSi2) heating elements (U-type, W-type, L-type, straight)

- Advantages: Handles extreme heat, corrosion-resistant, easy to install, supports thermal expansion and contraction

- Product Category: Molybdenum Disilicide (MoSi2) heating element accessory

- Inventory: In stock

- After-Sales Service: Global service center support

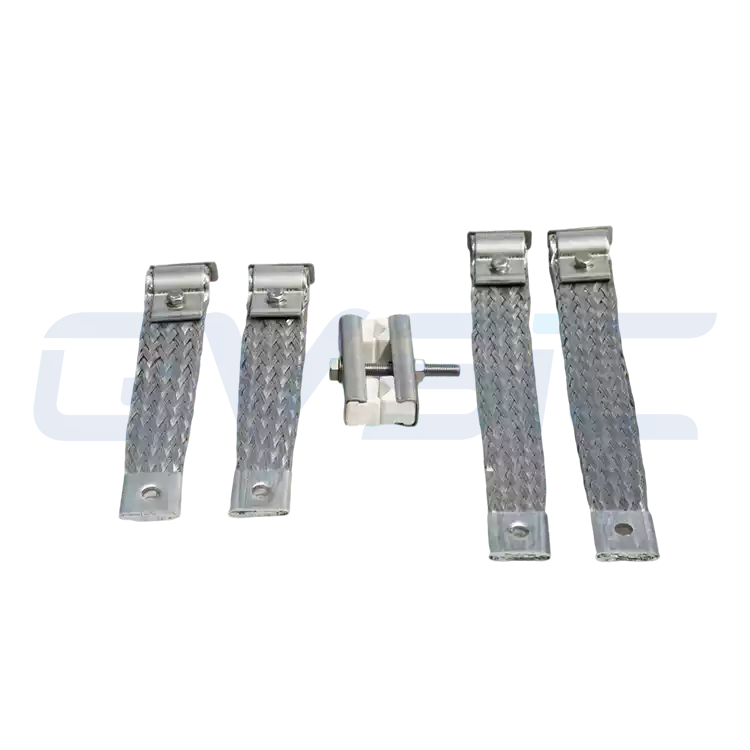

Mosi2 Heating Element Combination Straps

- Materials: Aluminum foil and stainless steel (heat-resistant steel)

- Current: 25-800A

- Width: 8-50mm

- Thickness: 1-3.5mm

- Single Wire Diameter: 0.15-3mm

- Length: Customizable

- Appearance: Smooth, bright, flexible

- Electrical Property: High conductivity

- Product Category: Furnace spare part

- Applications: High-temperature furnaces, heating testing equipment

- Inventory: In stock

- Origin: China

- Packaging: Carton or export wooden crate

- After-Sales Service: Global service center support

Ceramic Holders for MoSi2 Heaters

- Materials: Insulating ceramic (high-density alumina or ceramic fibre) and stainless steel (heat-resistant steel)

- Components: Stainless steel angle brackets, hex nuts, hex bolts, two insulating ceramic plates

- Diameters: 3/6mm, 4/9mm, 6/12mm, 9/18mm, 12/24mm

- Temperature: Up to 1900℃

- Appearance: White ceramic plates, high-temperature resistant; silver stainless steel clips, smooth

- Voltage: 110-480V

- Packaging: Carton

- Applications: Suitable for Molybdenum Disilicide (MoSi2) heating elements (U-type, W-type, L-type, straight)

- Advantages: Tough enough for extreme heat, corrosion-resistant, supports external installation, handles thermal expansion and contraction with ease

- Inventory: In stock

- After-Sales Service: Global service center support

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support