Protective Gases for Atmosphere Furnaces: Hydrogen vs Nitrogen vs Argon

With over 20 years of experience in high-temperature industrial applications, I understand the crucial role protective gases play…

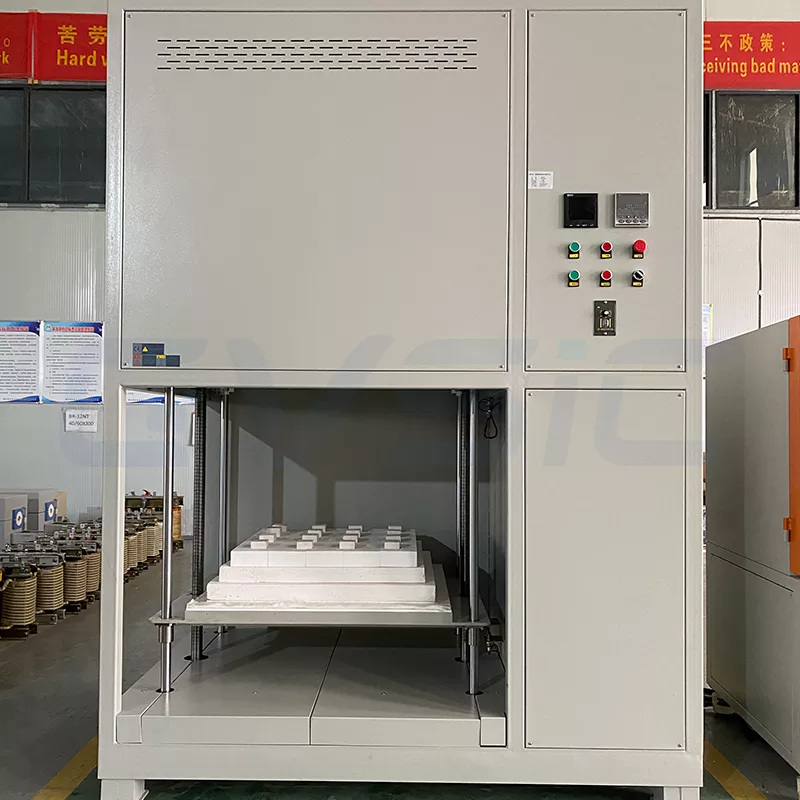

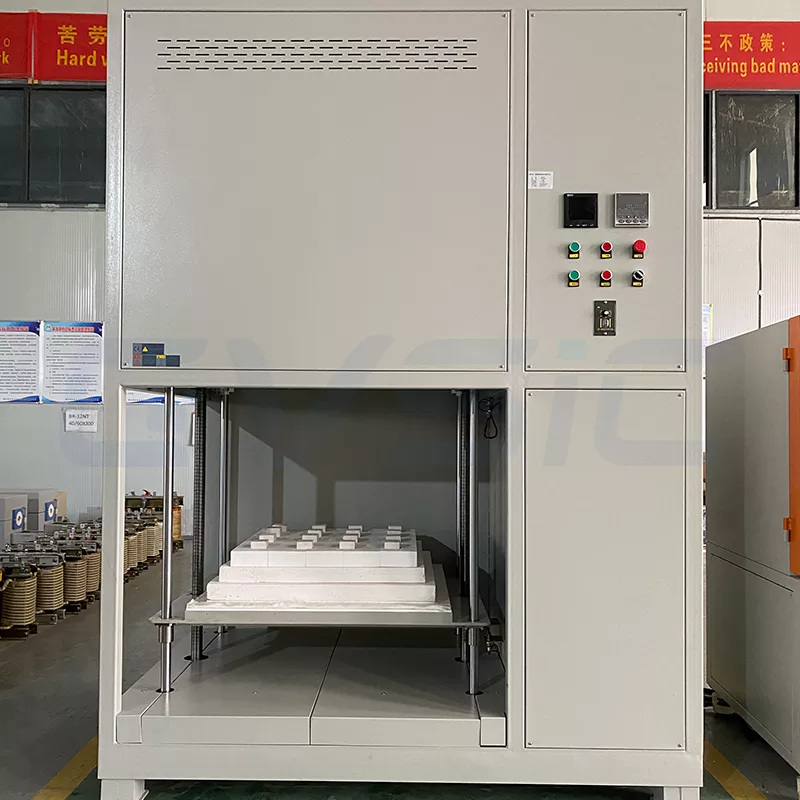

Engineered for precise sintering of ceramics and powders, the CVSIC Retort Atmosphere Furnace reaches 1000°C with PID control, hot-wall heating, and support for inert/oxidizing atmospheres. Ideal for research, testing, and small-scale production. Customization available. Contact us for details.

CVSIC Retort Atmosphere Furnace is a high-efficiency thermal processing system designed for precise sintering, annealing, and heat treatment in controlled atmospheric conditions. Utilizing a hot-wall external heating design, it separates the heating elements from the furnace chamber, significantly extending component lifespan and reducing the risk of contamination.

It supports inert (N₂, CO₂, Ar) and oxidizing atmospheres (air, oxygen) with a vacuum level up to 7×10⁻³ Pa, making it suitable for a broad range of high-purity material processes, including ceramics, powder metallurgy, electronic materials, and rare earth research. The system combines PID temperature control, modular atmosphere control, and multi-layer safety protection, making it a dependable choice for laboratories, R&D centers, and production environments.

External Hot-Wall Heating: Heating elements are placed outside the furnace chamber, avoiding direct material contact and improving component life and thermal stability.

High Temperature & Precision Control: Maximum temperature of 1000°C; operating temperature up to 950°C. The PID controller ensures ±1°C accuracy (±2°C during gas charging), with ±5°C uniformity across the working zone.

Versatile Atmosphere Support: Compatible with N₂, Ar, CO₂, oxygen, and air; customizable gas inlets and flow control (float/proton flowmeters). Cold-state vacuum up to 7×10⁻³ Pa.

Robust Furnace Chamber: Heat-resistant steel structure with corrosion-resistant insulation, providing stability under repeated thermal cycling.

Advanced Safety System: Features include over-temperature alarms, gas protection interlocks, an explosion-proof design, and multi-mode gas emissions, ensuring safe operation and compliance with environmental regulations.

Energy Efficient: Optimized thermal insulation and structure reduce heat loss, improving energy efficiency during extended cycles.

User-Friendly Control: Manual and automatic operation modes are supported, with heating rates of up to 10°C/min, allowing for flexible process tuning.

To meet varying industrial and academic needs, CVSIC offers full-scale customization options:

Note: Specifications can be customized. Contact us to discuss your specific process requirements.

Whether you are developing advanced ceramics or conducting cutting-edge materials research, CVSIC’s Retort Atmosphere Furnace offers precision, stability, and customization to fit your needs.

Contact our technical team today for consultation, pricing, or a tailored solution.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

With over 20 years of experience in high-temperature industrial applications, I understand the crucial role protective gases play…

Having worked in the high-temperature industrial sector for many years, I fully understand how heavily powder metallurgy (PM)…

Vacuum vs. Atmosphere Tube Furnaces: Selecting the Optimal Equipment for Your Experiments Sample oxidation or contamination in high-temperature…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support