Comprehensive Guide to Tube Furnaces: Types, Principles, and Applications

What is a Tube Furnace? Your Gateway to High-Temperature Applications Tube furnaces are essential high-temperature heating systems widely…

The CVSIC Steam Activation Tube Furnace supports dynamic sintering and steam activation at 1100 °C, equipped with 310S heat-resistant steel furnace tubes and a 50-segment intelligent temperature control system. It is suitable for powder and granular materials, as well as lithium-ion batteries and ceramic sintering. It provides high vacuum (-0.08 MPa) and inert atmosphere support, meeting global research and production needs. Contact us now!

The CVSIC Steam Activation Tube Furnace is an advanced thermal processing system explicitly designed for sintering and activating powder and granular materials. It features dynamic sintering and integrated steam activation, ensuring materials are continuously and evenly heated throughout the process. This design delivers high-efficiency thermal transfer and consistent sintering quality.

The furnace chamber is constructed with high-purity alumina polycrystalline fibre insulation and uses molybdenum-containing resistance wires for stable heating up to 1100°C (recommended operating temperature 1000°C). The 310S stainless steel rotating tube (Ø80 mm at the narrow end, Ø300 mm at the wide end, with a heating zone of 400 mm) features four lifting plates to enhance material turnover. The tube rotates at 0–7 rpm and can tilt between 0 ° and 15° to facilitate effective dynamic sintering.

Integrated with a 6 kW steam generator (8 kg/h), this furnace supports water-vapor activation to enhance the physical and chemical characteristics of treated materials. Equipped with a 50-segment programmable controller, the temperature accuracy is ±1°C, with thermal uniformity within ±5°C. It is ideal for small-scale production and R&D in the battery, ceramic, and chemical materials industries.

CVSIC provides full-service customisation to meet your unique production and R&D demands:

Contact CVSIC for fully customised steam activation sintering solutions tailored to your industry. Worldwide orders and technical consultation available.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

What is a Tube Furnace? Your Gateway to High-Temperature Applications Tube furnaces are essential high-temperature heating systems widely…

Rotary vs. Fixed Tube Furnaces: Choosing the Ideal Solution for Your Process When processing powder materials, issues like…

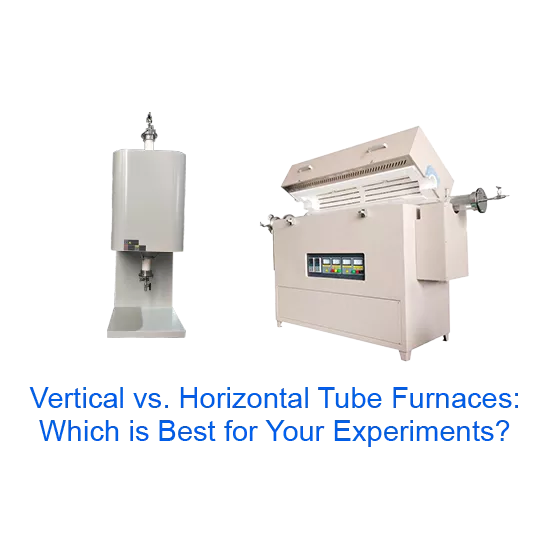

Vertical vs. Horizontal Tube Furnaces: Choosing the Right Equipment for Your Needs When selecting tube furnaces for materials…

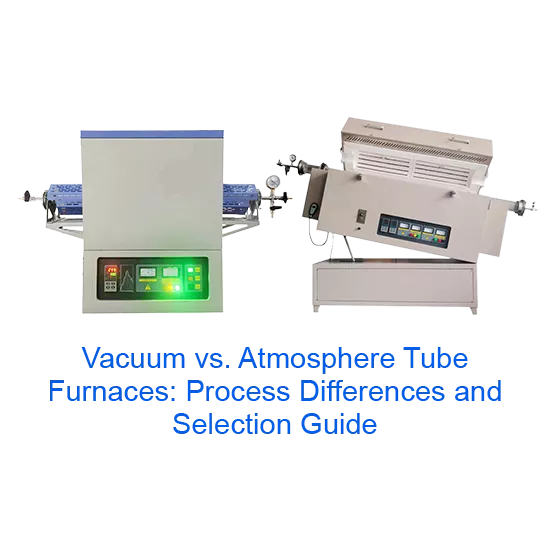

Vacuum vs. Atmosphere Tube Furnaces: Selecting the Optimal Equipment for Your Experiments Sample oxidation or contamination in high-temperature…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support