Global High-Temperature Industrial Heating Solutions

Welcome to our comprehensive range of high-performance heating elements and industrial furnace solutions for high-temperature industries.

We specialize in SiC heating elements, MoSi2 heating elements, furnace accessories, and advanced industrial furnaces, delivering customized B2B solutions for ceramics, metallurgy, glass, electronics, and more.

Explore our product categories below to discover how our cutting-edge technology can enhance your high-temperature processes.

SIC Heating Elements & Rods

SiC heating elements are designed for high-temperature environments (up to 1650°C in oxidizing atmospheres), offering exceptional durability and efficiency.

DB Type SiC Heater Rods

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: DB Type

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

Straight (ED type) SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: ED/Straight/ROD/RR/GD

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

U-Type SiC Heating Elements

- Material: High-purity silicon carbide (SiC), ≥99% content

- Shape: U-Shaped SiC Heating Element

- Power Supply: 220V/380V

- Manufacturing Process: High-quality silicon carbide blank, high-temperature silicon carbide recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625℃

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

H-Type SiC Heating Elements

- Product Name: H-Type Silicon Carbide Heating Element (SiC Rod)

- Material: High-purity green hexagonal silicon carbide (SiC)

- Components: Aluminum braid, H-type stainless steel clamp (M-type clip)

- Diameter: 8-65mm (cold end/hot end)

- Temperature: Up to 1625℃ (oxidizing atmosphere)

- Voltage: 110-480V

- Appearance: Gray-green rod, smooth surface

- Packaging: Carton or export wooden crate

- Lifespan: Up to 2000 hours of continuous use

W-Type SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Shape: W-Type SIC Heating Rods

- Power Supply: 110-480V electric

- Manufacturing Process: High-quality SiC billet, high-temperature silicification recrystallization

- Diameter: 12-55mm

- Operating Temperature: Up to 1625℃

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

SG Type SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Shape: SS/SC/LD

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

SCR SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: SD/SCR/LS

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

Slot type (UX) SiC Heating Element

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: Slot type (UX-Type) SiC Heater

- Power Supply: 110-480V electric

- Manufacturing Process: High-quality SiC billet, high-temperature silicification recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

- Brand: CVSIC

MoSi2 Heating Elements & Rods

MoSi2 heating elements are the go-to choice for extremely high-temperature applications, operating stably up to 1850°C.

Straight (I-Type) MoSi2 Heating Elements

- Material: Molybdenum Disilicide (MoSi2)

- Shape: Straight/I-Type

- Power Supply: 220-480V

- Grade: 1700/1800/1900

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

W Shape MoSi2 Heating Elements

- Material: Molybdenum Disilicide (MoSi2)

- Shape: W-Type

- Power Supply: 220-480V

- Grade: 1700/1800/1850

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

U Shape MoSi2 Heating Rod

- Material: Molybdenum Disilicide (MoSi2)

- Power Supply: 220-480V

- Grade: 1700/1800/1850

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

L Shape Molybdenum Disilicide Rod

- Product Specifications

- Material: Molybdenum Disilicide (MoSi2)

- Shape: L-Type

- Power Supply: 220-480V

- Grade: 1700/1800/1850

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

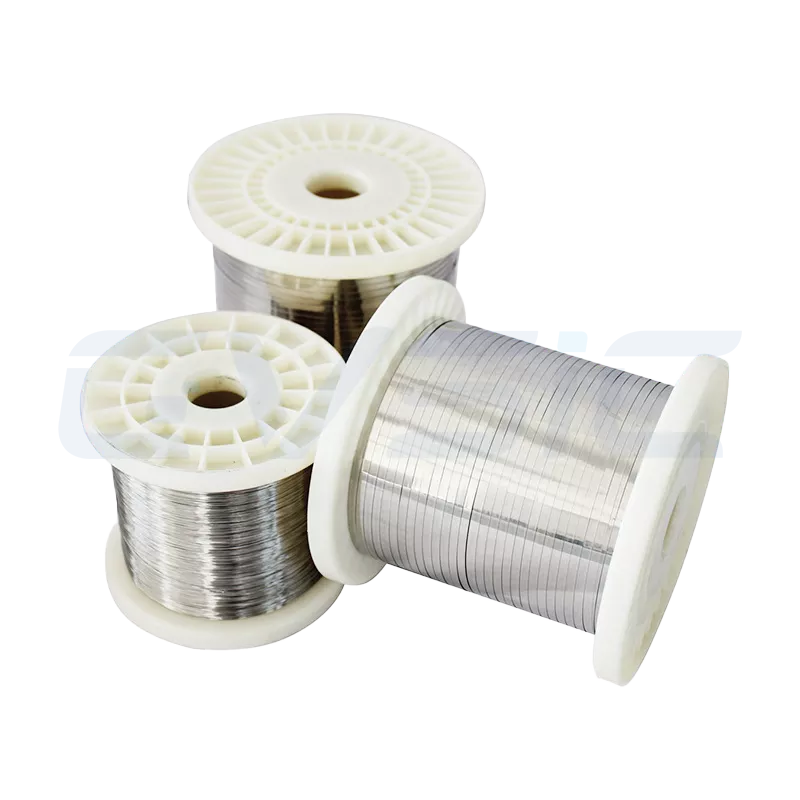

FeCrAl heating Wire

FeCrAl Heating wire is all over industrial kilns, heat treatment gear, lab heaters, and always-on industrial heating systems.

0Cr27Al7Mo2 Wire Kanthal APM Alternative

- Model: CV-0Cr27Al7Mo2

- Alloy Grade: Fe–Cr–Al–Mo high-temp resistance alloy

- Main Composition: Fe: Bal., Cr ≈27%, Al ≈7%, Mo (trace)

- Max Temp: ≤ 1400°C

- Resistivity (20°C): 1.50 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr21Al6Nb Resistance Wire Kanthal A1 Alternative

- Model: CV-0Cr21Al6Nb

- Alloy Grade: Fe–Cr–Al–Nb resistance alloy

- Main Composition: Fe: Bal., Cr ≈21%, Al ≈6%, Nb (trace)

- Max Temp: ≤ 1350°C

- Resistivity (20°C): 1.45 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr25Al5 Resistance Wire

- Model: CV-0Cr25Al5

- Alloy Grade: 0Cr25Al5 (FeCrAl 255)

- Main Composition: Fe: Bal.; Cr: 24–26; Al: 4.8–6.0; Mo: ≤0.5

- Max Temp: 1300°C

- Resistivity (20°C): 1.42 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr21Al6 Resistance Wire

- Model: CV-0Cr21Al6

- Alloy Grade: 0Cr21Al6 (FeCrAl 216)

- Main Composition: Fe: Bal.; Cr: 20–22; Al: 5.0–7.0; Mo: ≤0.5

- Max Temp: 1250–1300°C

- Resistivity (20°C): 1.35 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr23Al5 Alloy Wire

- Model: CV-0Cr23Al5

- Alloy Grade: 0Cr23Al5 (FeCrAl 235)

- Main Composition: Fe: Bal.; Cr: 22–24; Al: 4.5–6.0; Mo: ≤0.5

- Max Temp: 1250°C

- Resistivity (20°C): 1.40 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Tensile Strength: Tensile Strength ≥650 MPa

1cr20al3 Wire

- Model: CV-1Cr20Al3

- Alloy Grade: 1Cr20Al3 (FeCrAl low-aluminum resistance alloy)

- Main Composition: Fe: Bal., Cr 19–21%, Al 2.5–3.5%

- Max Temp: 1000–1100°C

- Resistivity (20°C): 1.25–1.35 μΩ·m

- Density: 7.2 g/cm³

- Forms Available: Wire, flat strip, ribbon, coiled, seamless spools

- Best Atmosphere: Air / Mildly oxidizing

1Cr13Al4 Alloy Wire

- Model: CV-0Cr21Al6

- Alloy Grade: 0Cr21Al6 (FeCrAl 216)

- Main Composition: Fe: Bal.; Cr: 20–22; Al: 5.0–7.0; Mo: ≤0.5

- Max Temp: 950°C

- Resistivity (20°C): 1.20-1.30 μΩ·m

- Density: 7.2 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

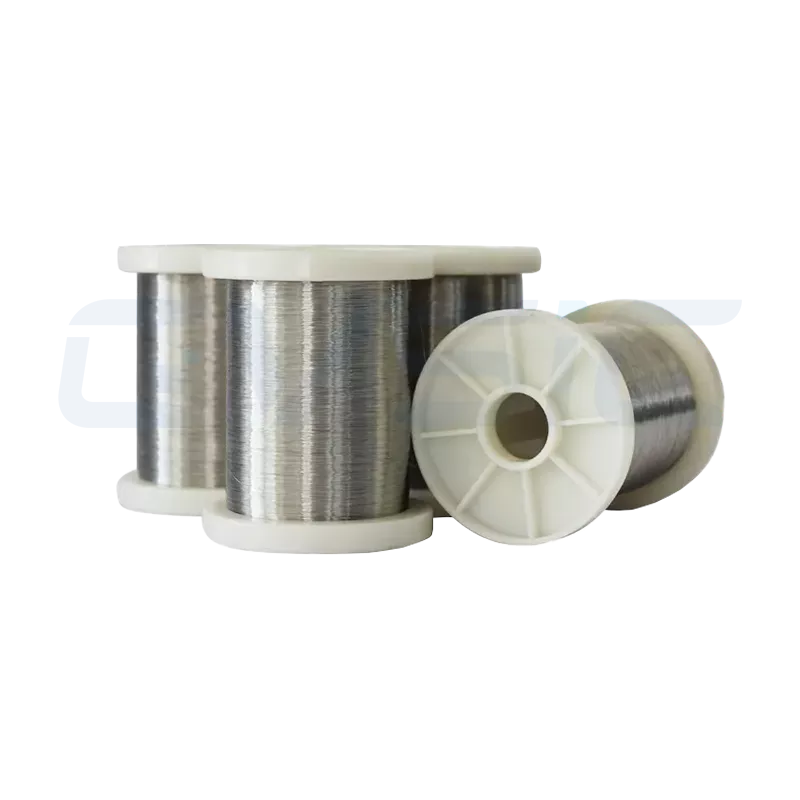

NiCr heating Wire

NiCr resistance wire is known for rock-solid resistance stability, consistent heat response, and tough mechanical strength.

Cr20Ni80 Heating Wire

- Model: CV-Cr20Ni80

- Alloy Grade: Ni80Cr20

- Main Composition: Ni: Bal., Cr: 20–23, Fe: ≤1%

- Max Temp: 1200°C

- Resistivity (20°C): 1.09 μΩ·m

- Density: 8.4 g/cm³

- Forms Available: Diameters: 0.018–10mm; Strips: 0.02–2mm; Custom tolerances

- Common Uses: High-temp furnaces, lab gear, ceramic sintering, cutting wires, appliance heaters

Cr30Ni70 Heating Wire

- Model: CV-Cr30Ni70

- Alloy Grade: NiCr70/30

- Main Composition: Ni: Bal. (about 70%), Cr: 28–31%, Fe: ≤1.0%

- Max Temp: 1200°C

- Resistivity (20°C): 1.18 μΩ·m

- Density: 8.1 g/cm³

- Forms Available: Diameters: 0.02–10mm (round) Strips: 0.02–2mm Custom flat wire, rods, coils

- Common Uses: Industrial furnace wires – High-temp elements – Ceramic heaters – High-temp ovens/tunnel kilns – Mold heating, lab furnaces

Cr20Ni35 Heating Wire

- Model: CV-Cr20Ni35

- Alloy Grade: Nichrome 35/20

- Main Composition:Ni: Cr: ≈20%, Ni: ≈35%, Fe: Bal.

- Max Temp: 1100–1150°C

- Resistivity (20°C): 1.02 μΩ·m

- Density: 8.0 g/cm³

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Mid-high temp industrial furnaces, ovens, heating tubes, durable elements

Cr20Ni30 Alloy Heatin Wire

- Model: CV-Cr20Ni30

- Alloy Grade: Nichrome 70/30, Ni70Cr30

- Main Composition:Ni: Cr: 18–21%, Ni: 30–34%, Fe: Bal.

- Max Temp: 1100°C

- Resistivity (20°C): 1.04 μΩ·m

- Density: 7.9 g/cm³

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Heaters, electric tubes, hair dryer wires, damping/cutting wires (foam/plastic)

Cr15Ni60 Alloy Wire

- Model: CV-Cr15Ni60

- Alloy Grade: Nichrome 60/15

- Main Composition:Ni: 55–61%, Cr: 15–18%, Fe: Bal.

- Max Temp: 1100°C

- Resistivity (20°C): 1.12 μΩ·m

- Density: 8.2 g/cm³

- Forms Available: Wire, strip, flat; 0.03–8mm diameters; custom coiling

- Common Uses: Industrial furnaces, oven elements, heating tubes, mold heaters, durable wires

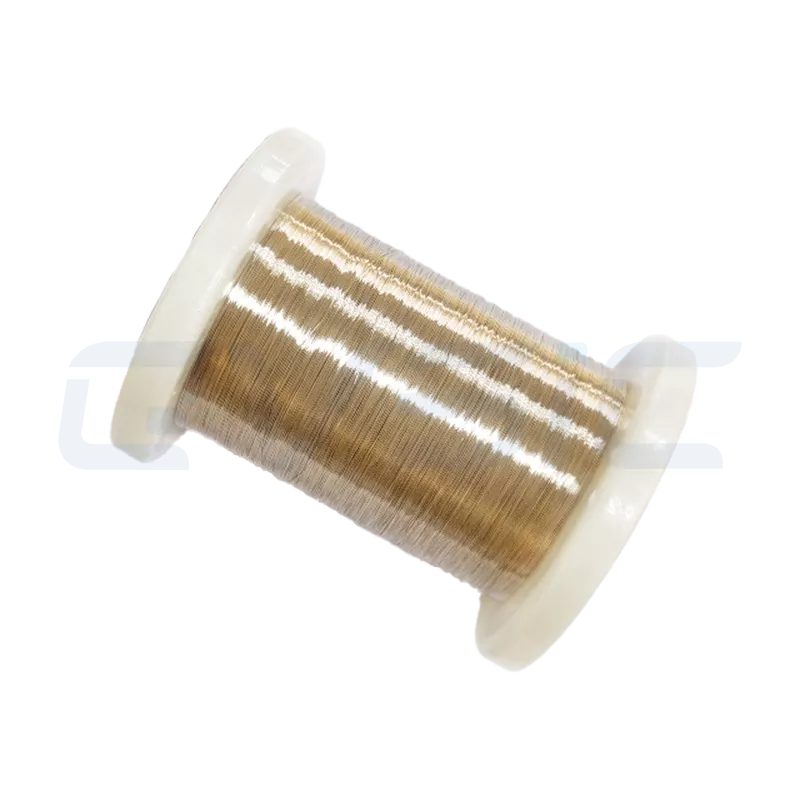

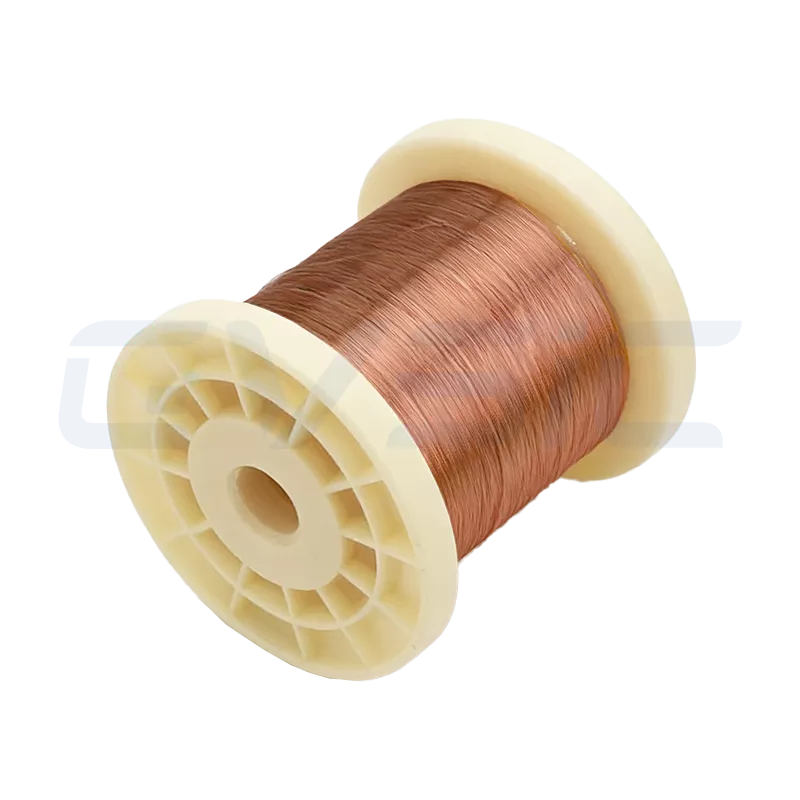

CuNi heating Wire

CuNi Resistance Wire is a family of resistance alloys with copper as the base and nickel as the main additive.

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

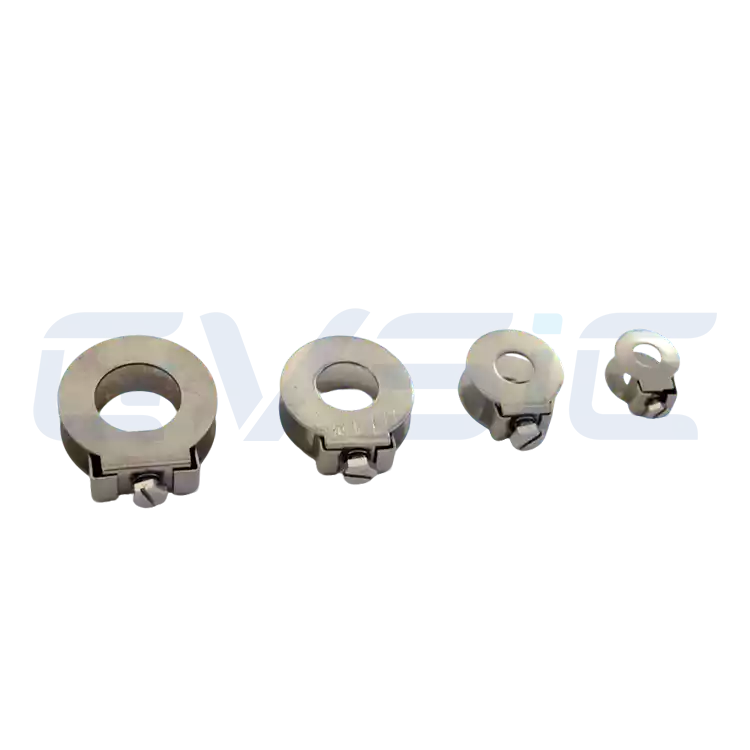

SiC Heating Elements Accessories

We offer a range of SiC Heating Elements accessories to ensure optimal performance and easy installation.

Stainless Steel G Clamps

- Material: Heat-resistant spring steel (with aluminum braid)

- Appearance: Silver, smooth

- Diameter: 8-65mm

- Application: Silicon carbide heating element accessory

- Shape: G-type

- Voltage: 110-480V

- Packaging: Carton or export wooden crate

- After-Sales Service: Global service center support

- Advantages: Stands up to corrosion and oxidation, rust-free, easy installation

Stainless Steel C Clamps

- Material: Heat-resistant spring steel

- Appearance: Silver, Polished

- Diameter: 8-65mm

- Suitable for: Silicon carbide heating element accessories

- Shape: C-Type

- Voltage: 110-480V

- Packaging: Carton or export wooden crate

- After-Sales Service: Global service center support

- Advantages: Corrosion-resistant, oxidation-resistant, rust-proof, quick and straightforward setup

Aluminum Braid

- Material: Aluminum foil and stainless steel

- Current: 25-400A

- Width: 8-50mm

- Thickness: 1-3.5mm

- Length: Customizable as needed

- Electrical Properties: High conductivity

- Packaging: Carton or export wooden crate

- Applications: Furnace heating accessories

- After-Sales Service: Global service center support

H-Type Silicon Carbide Clamp

- Material: Heat-resistant spring steel

- Appearance: Silver, smooth

- Diameter: 8-65mm

- Suitable for: Silicon carbide heating element accessories

- Shape: H-Type (M-Type)

- Voltage: 110-480V

- Packaging: Carton or export wooden crate

- After-Sales Service: Global service center support

MoSi2 Heating Elements Accessories

We offer a range of MoSi2 Heating Elements accessories to ensure optimal performance and easy installation.

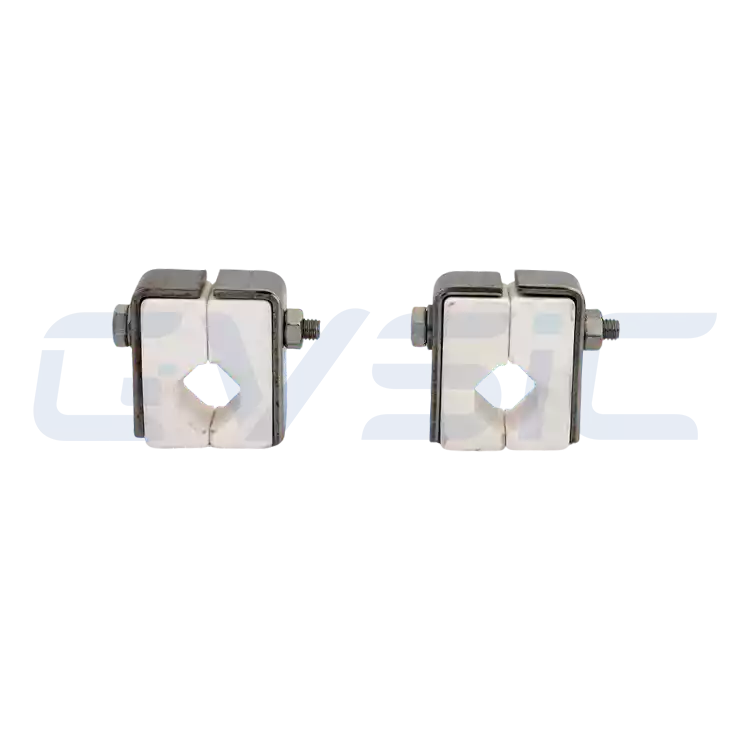

MoSi2 Heating Element two Shank Holders

- Materials: Insulating ceramic (high-density alumina ceramic) and stainless steel (heat-resistant steel)

- Components: Stainless steel angle brackets, hex nuts, hex bolts, two insulating ceramic blocks

- Diameters: 3/6mm, 4/9mm, 6/12mm, 9/18mm, 12/24mm

- Appearance: Silver stainless steel clips, smooth white ceramic blocks, high-temperature resistant

- Voltage: 110-480V

- Packaging: Carton

- Advantages: Handles extreme heat, is corrosion-resistant, easy to install, supports thermal expansion and contraction

- Inventory: In stock

- Product Category: MoSi2 heating element accessory

- After-Sales Service: Global service center support

MoSi2 Heating Element Single Shank Holders

- Material: Stainless steel (heat-resistant steel)

- Components: Stainless steel angle brackets, hex nuts, hex bolts

- Diameter Compatibility: 3/6mm, 4/9mm, 6/12mm, 9/18mm, 12/24mm

- Appearance: Silver, smooth

- Voltage: 110-480V

- Packaging: Carton

- Applications: Suitable for various MoSi2 heating elements (U-type, W-type, L-type, straight)

- Advantages: High-temperature resistant, corrosion-resistant, flexible installation, easy operation

- Product Category: MoSi2 heating element accessory

- Origin: China

- Minimum Order Quantity: 10 pieces

- Inventory: In stock

- After-Sales Service: Global service center support

Mosi2 Heating Element Plate Holders

- Materials: High-density alumina ceramic (Al₂O₃) and corrosion-resistant stainless steel (heat-resistant steel)

- Components: Hex nuts, hex bolts, two insulating ceramic plates

- Diameters: 3/6mm, 4/9mm

- Temperature: Up to 1900℃

- Appearance: Silver stainless steel clip, smooth; white ceramic plates, high-temperature resistant

- Voltage: 110-480V

- Packaging: Carton

- Applications: Suitable for various Molybdenum Disilicide (MoSi2) heating elements (U-type, W-type, L-type, straight)

- Advantages: Handles extreme heat, corrosion-resistant, easy to install, supports thermal expansion and contraction

- Product Category: Molybdenum Disilicide (MoSi2) heating element accessory

- Inventory: In stock

- After-Sales Service: Global service center support

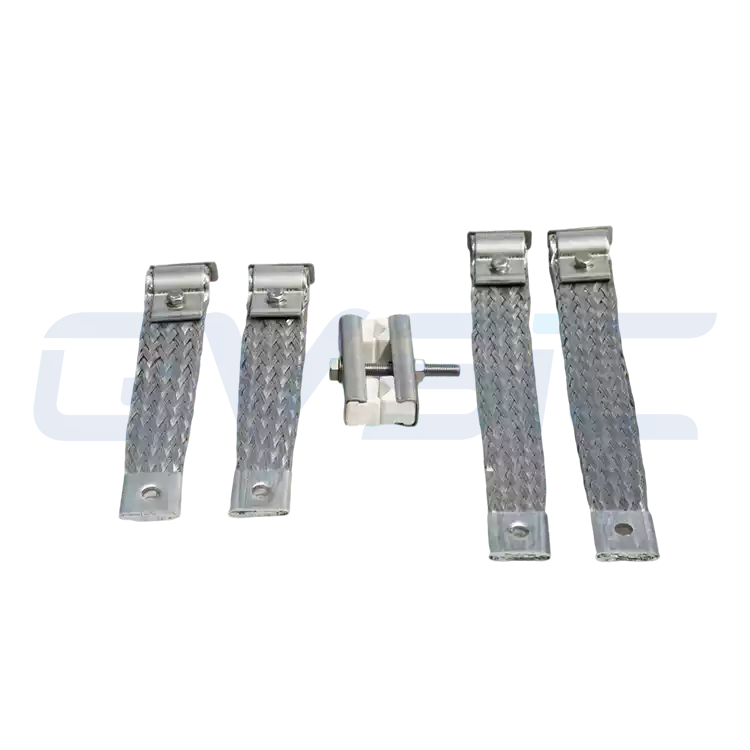

Mosi2 Heating Element Combination Straps

- Materials: Aluminum foil and stainless steel (heat-resistant steel)

- Current: 25-800A

- Width: 8-50mm

- Thickness: 1-3.5mm

- Single Wire Diameter: 0.15-3mm

- Length: Customizable

- Appearance: Smooth, bright, flexible

- Electrical Property: High conductivity

- Product Category: Furnace spare part

- Applications: High-temperature furnaces, heating testing equipment

- Inventory: In stock

- Origin: China

- Packaging: Carton or export wooden crate

- After-Sales Service: Global service center support

MoSi2 Heating Elements C Contact Clamp

- Materials: High-quality stainless steel and heat-resistant spring steel

- Sizes: Diameters 6mm, 9mm, 12mm

- Thickness: 2mm

- Voltage: 110-480V

- Appearance: Silver, smooth

- Packaging: Carton

- Advantages: Corrosion-resistant, high-temperature resistant, rust-free, rapid heating, long lifespan, easy installation and maintenance

- Usage: Used with aluminum braid to secure MoSi2 cold-end aluminum coating for efficient conductivity

- Product Category: MoSi2 heating element accessory

- Inventory: In stock

- Origin: China

Ceramic Holders for MoSi2 Heaters

- Materials: Insulating ceramic (high-density alumina or ceramic fibre) and stainless steel (heat-resistant steel)

- Components: Stainless steel angle brackets, hex nuts, hex bolts, two insulating ceramic plates

- Diameters: 3/6mm, 4/9mm, 6/12mm, 9/18mm, 12/24mm

- Temperature: Up to 1900℃

- Appearance: White ceramic plates, high-temperature resistant; silver stainless steel clips, smooth

- Voltage: 110-480V

- Packaging: Carton

- Applications: Suitable for Molybdenum Disilicide (MoSi2) heating elements (U-type, W-type, L-type, straight)

- Advantages: Tough enough for extreme heat, corrosion-resistant, supports external installation, handles thermal expansion and contraction with ease

- Inventory: In stock

- After-Sales Service: Global service center support

Ceramic Fiber Products

CVSIC provides customized and wholesale services for high performance ceramic fiber products and ceramic modules.

Ceramic Fiber Heating Module

- Name: CVSIC Ceramic Fiber Heating Module

- Temperature: 1100-1800 ℃

- Density: 300-700 kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂, and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Module

- Name: CVSIC Ceramic Fiber Module

- Temperature: 1050-1600 ℃

- Density: 160-240 kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂, and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Board

- Name: CVSIC ceramic fiber board

- Temperature: 1050-1800 ℃

- Density: 300-700 kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂, and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Bulk Cotton

- Name: CVSIC Ceramic Fiber Bulk Cotton

- Temperature: 1050-1600 ℃

- Density: None

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂,Cr₂O₃ and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Blanket & Wool

- Name: CVSIC ceramic fiber blanket

- Temperature: 1050-1600 ℃

- Density: 64-170 kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition:AL₂O₃, SiO₂, and ZrO₂

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Paper

- Name: CVSIC ceramic fiber paper

- Temperature: 1200-1600 ℃

- Density: 180-220kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂, and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Shaped Parts

- Name: CVSIC Ceramic Fiber Shaped Products

- Temperature: 1200-1800 ℃

- Density: 300-700kg/m³

- Size: customized according to customer requirements

- Composition Adjustment: AL ₂ O ₃, SiO ₂, ZrO ₂ and other compositional ratios

- Surface Treatment: Surface curing agent or refractory mud coating

- Packaging Customization: Carton or wooden crate Packaging

- Technical Support: Provide selection advice, mold design and installation Guidance

Ceramic Fiber Textiles

CVSIC provides customized ceramic fiber fabrics at competitive prices for you.

Ceramic Fiber Yarn

- Name: CVSIC Ceramic Fiber Yarn

- Temperature: 650-1260 ℃

- Density: 500-650 kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂, and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Tape

- Name: CVSIC Ceramic Fiber Tape

- Temperature: 650-1260 ℃

- Density: 500-650 kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂, and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Sleeves

- Name: CVSIC Ceramic Fiber sleeves

- Temperature: 650-1260 ℃

- Density: 500-650 kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂, and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Cloth

- Name: CVSIC Ceramic Fiber Cloth

- Temperature: 650-1260 ℃

- Density: 500-650 kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂, and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Ceramic Fiber Rope

- Name: CVSIC Ceramic Fiber Rope

- Temperature: 650-1260 ℃

- Density: 500-650 kg/m³

- Size: customized according to customer requirements

- Adjustment of chemical composition: AL₂O₃, SiO₂, ZrO₂, and other compositional ratios

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

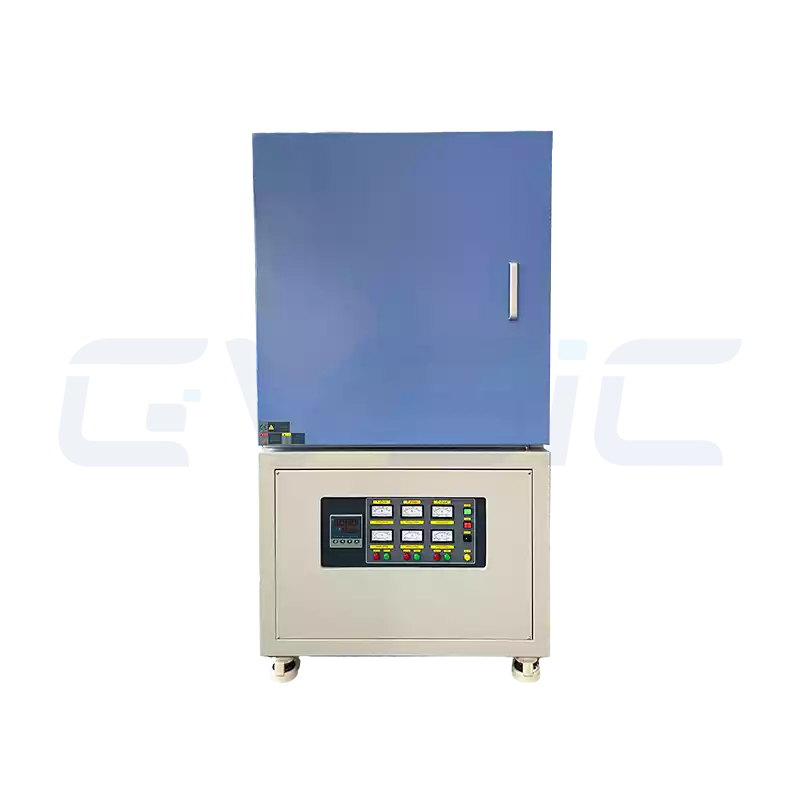

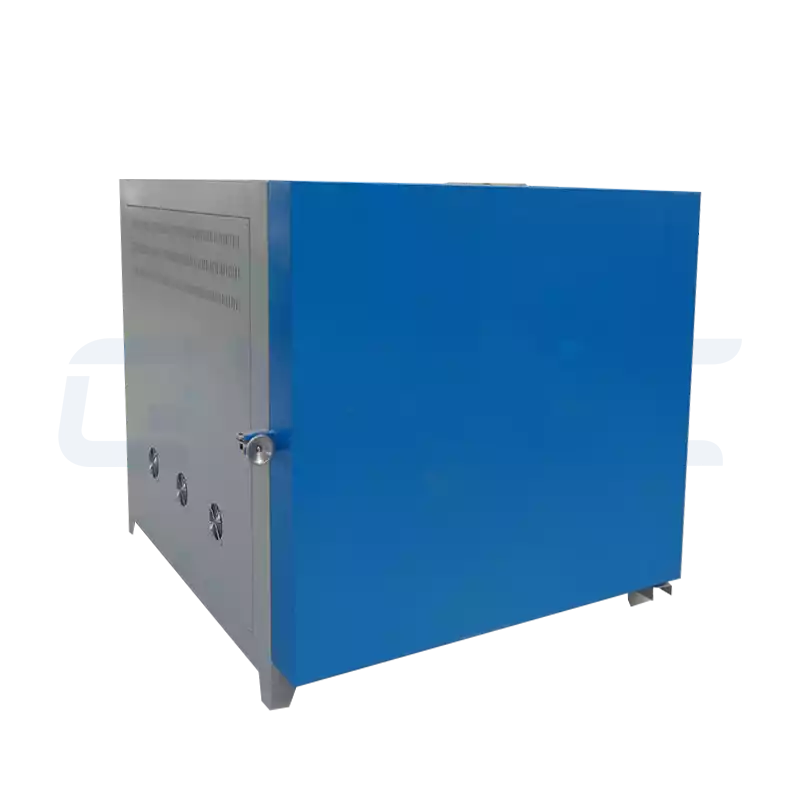

Muffle furnaces

CVSIC offers box muffle furnaces covering multiple temperature ranges of 1200°C, 1400°C, 1700°C, 1800°C, with volumes from 1L to 1000L, and customizable according to user needs.

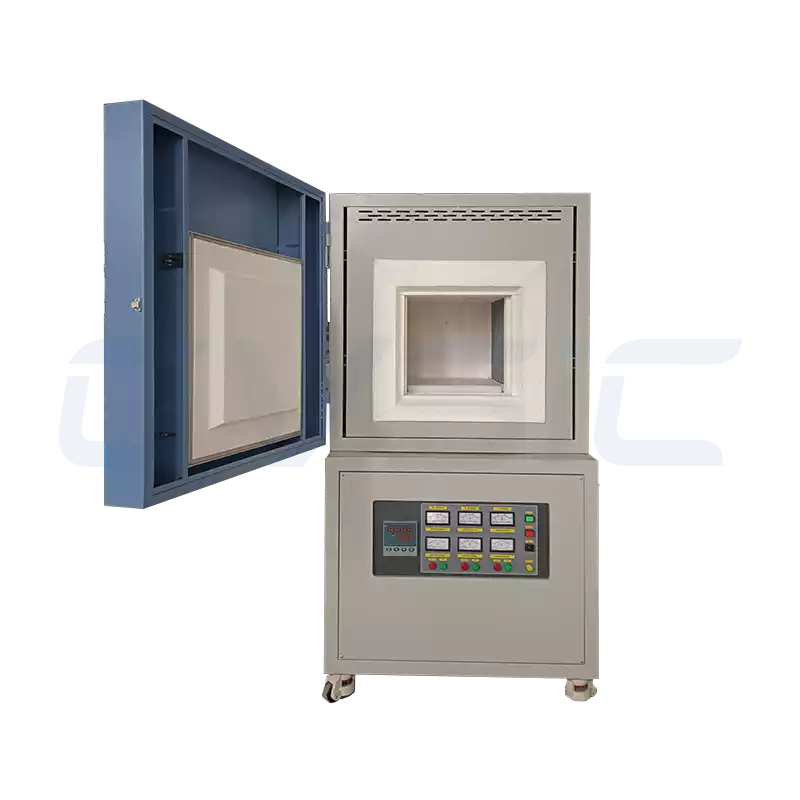

1800°C Industrial Muffle Furnace

- Name: CVSIC 1800°C Industrial Muffle Furnace

- Temperature: Maximum of 1800°C and operating temperature of 1700°C

- Heater: MoSi2 Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1800°C Small Muffle Furnace

- Name: CVSIC 1800°C Small Muffle Furnace

- Temperature: Maximum temperature of 1800°C, with stable operation at 1700°C

- Heater: U-shaped MoSi2 heating element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Large Muffle Furnace

- Name: CVSIC 1700°C Large Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Medium Muffle Furnace

- Name: CVSIC 1700°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Small Muffle Furnace

- Name: CVSIC 1700°C Small Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1400°C Large Muffle Furnace

- Name: CVSIC 1400°C Large Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1400°C Medium Muffle Furnace

- Name: CVSIC 1400°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

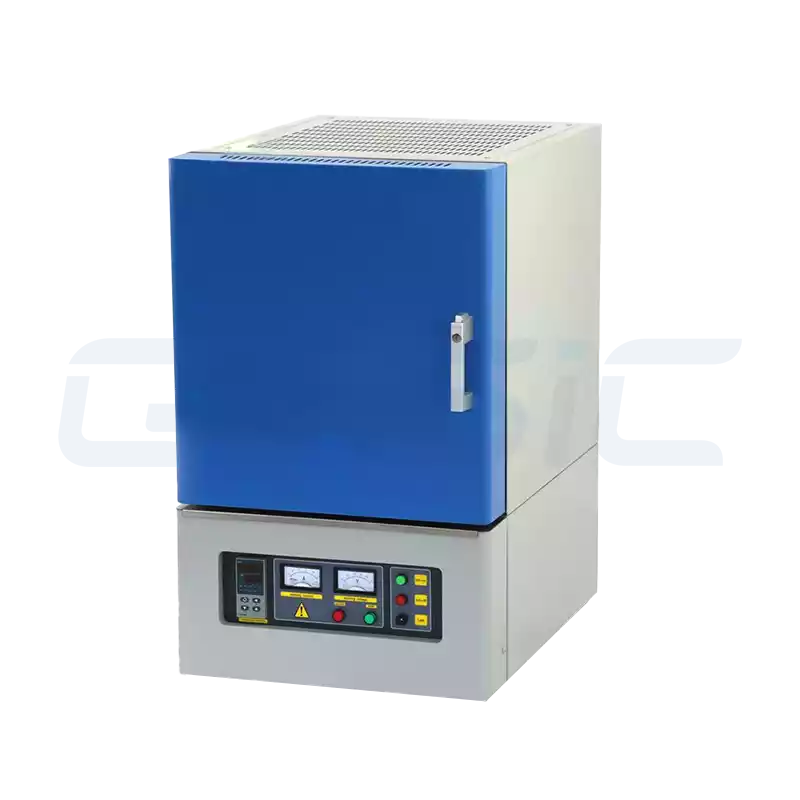

1400°C Small Muffle Furnace

- Name: CVSIC 1400°C Small Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1200°C Large Muffle Furnace

- Name: CVSIC 1200°C Large Muffle Furnace

- Temperature: Maximum temperature of 1200°C, with stable operation at 1100°C

- Heater: HRE FeCrAl resistance wire

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1200°C Medium Muffle Furnace

- Name: CVSIC 1200°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1200°C, with stable operation at 1100°C

- Heater: HRE FeCrAl wire

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

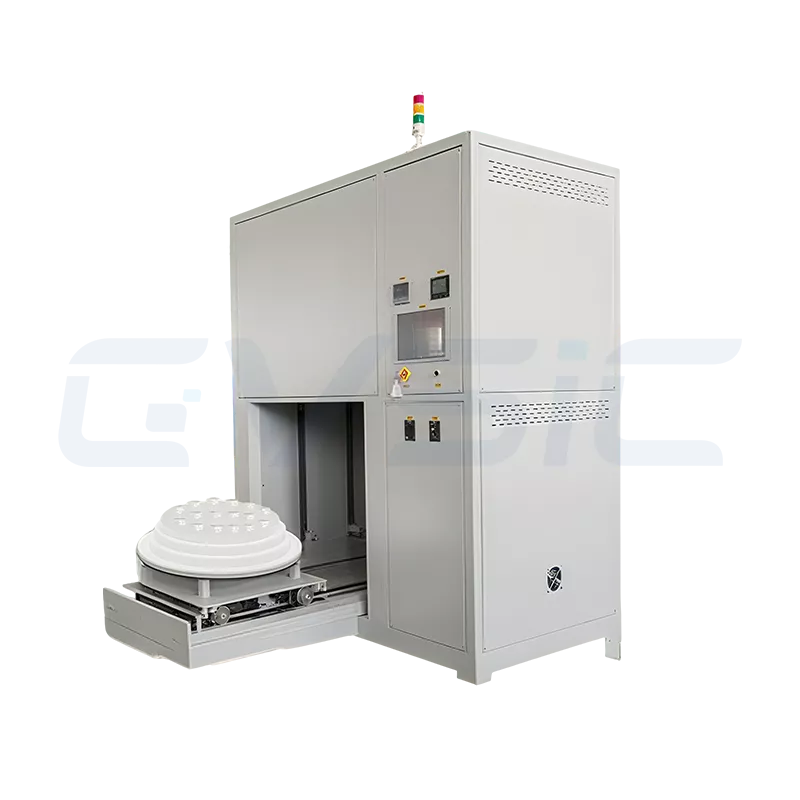

Dental Furnace

CVSIC provides customized Dental Furnace at competitive prices for you.

Dental Zirconia Sintering Furnace Plus

- Name: CVSIC Plus Zirconia Sintering Furnace

- Furnace Chamber: The Japanese-imported Chamber

- Temperature: With a maximum temperature of 1700℃

- Heater: MoSi₂ Element

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Dental Vacuum Porcelain Furnace

- Name: Dental Vacuum Porcelain Furnace

- Furnace Chamber: Quartz Chamber

- Temperature: With a maximum temperature of 1200℃

- Heater: resistance wire heating elements

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Dental Zirconia Sintering Furnace

- Name: Dental Zirconia Sintering Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With a maximum temperature of 1700℃

- Heater: MoSi₂ Element

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Lift-Type Dental Zirconia Sintering Furnace

- Name: Lift-Type Dental Zirconia Sintering Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With a maximum temperature of 1700°C (continuous operation at 1600°C)

- Heater: MoSi₂ Element

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

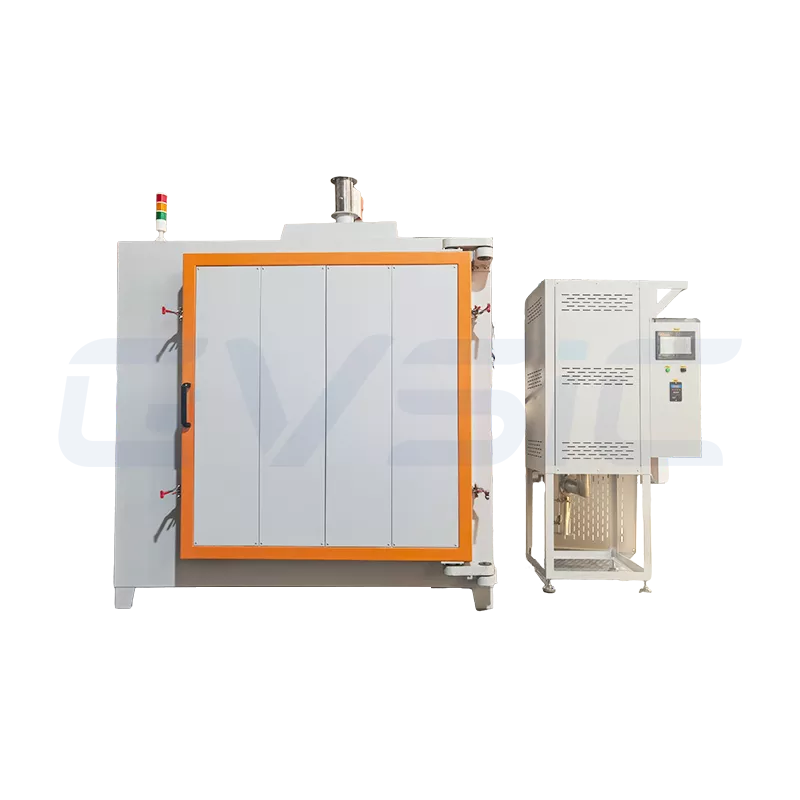

Atmosphere Furnace

CVSIC provides customized Atmosphere Furnace at competitive prices for you.

Hydrogen Furnace

- Name: Hydrogen Sintering Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With maximum working temperature 1600℃

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Retort Atmosphere Furnace

- Name: Retort Atmosphere Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: Maximum temperature of 1000°C; operating temperature up to 950°C

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Atmosphere Box Furnace

- Name: CVSIC Atmosphere Box Furnace

- Temperature: 1100-1700 ℃

- Heater: SiC Element, MoSi₂ Element

- Atmosphere System: N₂, CO₂, Ar

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

Atmosphere Hot Press Furnace

- Name: Atmosphere Hot Press Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: 1200°C, 1400°C, or 1700°C

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Debinding Furnace

CVSIC offers comprehensive debinding furnace systems, enhancing your production efficiency from design to ongoing support.

Hot Air Circulation Debinding Furnace

- Name: Hot Air Circulation Debinding Furnace

- Furnace Chamber: Stainless Steel Chamber

- Heating Element: Resistance Wire

- Maximum Temperature: 650°C

- Operating Temperature: 600°C

- Vacuum Level: Non-Vacuum

- Available Atmosphere: Inert Atmosphere (N₂, CO₂, Ar₂, etc.)

- Application Processes: Sintering, Debinding Sintering, Heat Treatment

Debinding and Pre-Sintering Integrated Furnace

- Name: Debinding and Pre-Sintering Integrated Furnace

- Furnace Chamber: Ceramic Fiber

- Heating Elements: Resistance Wire, SiC Heating Elements

- Maximum Temperature: 650°C, 1200°C

- Voltage: 380V

- Vacuum System: None

- Available Atmosphere: Inert atmosphere (N₂, CO₂, Ar₂, etc.)

- Process Applications: Sintering, Brazing, Debinding Sintering, Heat Treatment, Annealing

Lifting Atmosphere Sintering Furnace

- Name: Atmosphere debinding and sintering furnace

- Furnace chamber: Ceramic fiber

- Heating elements: MoSi2 heating elements

- Maximum temperature: 1700°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Available Atmosphere: Inert Gas (N₂, CO₂, Ar₂)

- Applications: Degreasing Sintering, Heat Treatment

Bottom Loading Debinding and Sintering Furnace

- Name: Degreasing and Sintering Furnace

- Furnace Lining: Ceramic Fiber

- Heating Elements: MoSi2 Heating Elements

- Maximum Temperature: 1750°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Process Applications: Degreasing Sintering, Heat Treatment

- Brand: CVSIC

Hydrogen Furnace

- Name: Hydrogen Sintering Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With maximum working temperature 1600℃

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

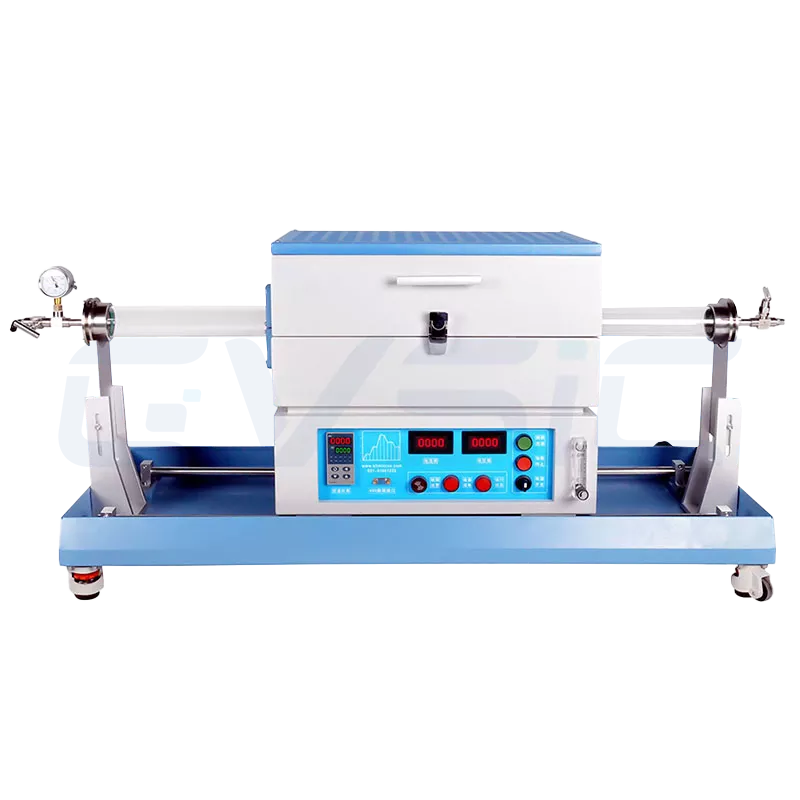

Tube Furnace

CVSIC provides customized Tube Furnace at competitive prices for you.

CVD Tube Furnace

- Name: CVSIC Vacuum CVD Tube Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With a maximum temperature of 1200℃, 1400℃, or 1600℃

- Heater: Resistance wire, SiC Heating Element, MoSi2 Element

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

PECVD Tube Furnace

- Name: CVSIC PECVD Tube Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With a maximum temperature of 1200℃

- Heater: Resistence wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Sliding Tube Furnace

- Name: Sliding Tube Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: maximum temperature 1200°C, and operating temperature 1100°C

- Heater: Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Multi-Zone Tube Furnace

- Name: Multi-Zone Tube Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: 1200°C, 1400°C, or 1600°C

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Vacuum Tube Furnace

- Name: Vacuum Tube Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: 1200°C, 1400°C, or 1600°C

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

Rotary Tube Furnace

- Name: CVSIC Rotary Tube Furnace

- Heating Element: Molybdenum-containing resistance wire

- Temperature: Max temperature of 1200℃, with 1100℃ continuous operation temperature

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Place of Origin: China

- Brand: CVSIC

Vertical Tube Furnace

- Name: CVSIC Vertical Tube Furnace

- Heating Element: FeCrAl, SiC Heating Elements, MoSi2 Heating Elements

- Temperature: 1200°C / 1400°C / 1600°C

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Place of Origin: China

- Brand: CVSIC

Steam Activation Tube Furnace

- Name: CVSIC Steam Activation Tube Furnace

- Heating Element: molybdenum-containing resistance wire

- Power: 3Kw

- Temperature: stable heating up to 1100°C , recommended operating temperature 1000°C

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- Brand: CVSIC

Our B2B Services

Global Sales and Wholesale: We provide high-quality SiC and MoSi2 heating elements, accessories, and industrial furnaces to global clients. Ample inventory ensures fast delivery, meeting timelines from small labs to large-scale industrial production.

Customization Services: We get that every furnace application is unique, so we offer tailored solutions. From custom-shaped heating elements to specialized furnace designs, our engineering team works with you to ensure top performance.

Technical Support and Consulting: Our industry experts provide comprehensive support, including material selection, furnace design, and maintenance. We offer complimentary engineering consultations for new furnace installations or conversions from gas or oil to electric heating systems.

After-Sales Service: We offer comprehensive after-sales support, including installation guidance, maintenance advice, and replacement parts, to minimize downtime and ensure long-term reliability.

Our Competitive Advantages

Industry-Leading Expertise: With decades of experience in high-temperature industries, we understand the challenges your applications face.

Superior Product Quality: Our SiC and MoSi2 heating elements are manufactured using advanced processes, including hot pressing and sintering, to ensure high density and excellent performance.

Global Reach, Local Support: As a trusted global supplier, we combine worldwide logistics with localized support, ensuring timely delivery and prompt response services, regardless of your business’s location.

Energy Efficiency and Cost Savings: SiC elements consume less power for energy savings, while MoSi2 elements facilitate rapid heating and maintain stable resistance.

Commitment to Sustainability: We prioritize eco-friendly materials and processes, such as energy-efficient furnace designs and durable heating elements, which reduce the need for replacements and minimize environmental impact.

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support