Sinais de aquecimento irregular e aumento lento da temperatura

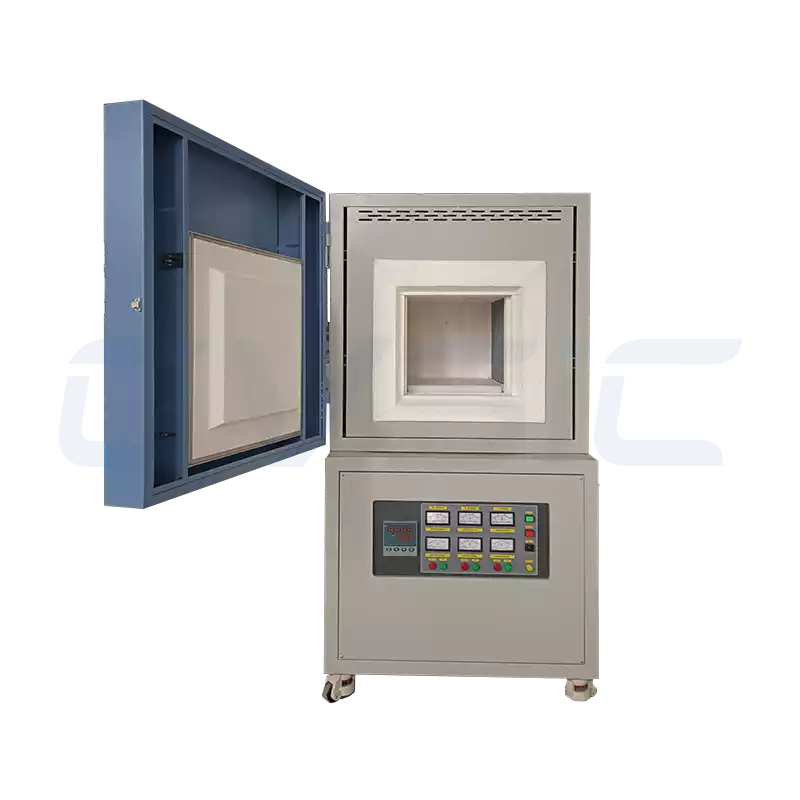

Em laboratório ou em ambiente industrial, forno de mufla os utilizadores deparam-se frequentemente com estes problemas reveladores:

- A temperatura definida não atinge o valor-alvo.

- Aparecem gradientes de temperatura significativos nas zonas do forno (por exemplo, variações de cima para baixo ou da frente para trás).

- As taxas de aquecimento abrandam visivelmente em comparação com uma unidade nova.

- As amostras apresentam sinterização irregular ou os resultados analíticos apresentam erros acrescidos.

Estes sintomas indicam normalmente uma perturbação do campo térmico interno ou um desvio do sistema de controlo.

Hoje, CVSIC acções comprovadas causas e soluções para o aquecimento desigual do forno de mufla, permitindo-lhe diagnosticar e resolver problemas rapidamente para um desempenho fiável.

Causas comuns e soluções para o aquecimento irregular em fornos de mufla

O aquecimento irregular ocorre quando a distribuição da temperatura na câmara do forno varia significativamente, frequentemente como um centro quente com extremidades mais frias ou pontos quentes isolados. Este facto pode comprometer a integridade da amostra, conduzindo, por exemplo, a uma sinterização inconsistente da cerâmica. De seguida, descrevemos as principais causas e soluções práticas.

Distribuição desigual ou envelhecimento dos elementos de aquecimento

- Fornos de fio de resistência(<1200℃): A exposição prolongada a altas temperaturas provoca a oxidação, aumentando a resistência e reduzindo a produção de calor.

- Elementos SiC (1400℃): Em ciclos prolongados, a resistência aumenta rapidamente, resultando em temperaturas mais baixas nos elementos afectados.

- Elementos MoSi2 (1600-1800℃): As fracturas frágeis ou a oxidação da tampa interrompem o aquecimento localizado.

- Em geral, a instalação incorrecta ou o envelhecimento localizado conduzem a uma radiação térmica inconsistente.

Soluções:

- Utilize um multímetro para verificar a consistência da resistência nas zonas de aquecimento.

- Substituir qualquer elemento se a resistência exceder o valor inicial em mais de 20%.

- Efetuar uma limpeza mensal para remover a poeira da superfície e a acumulação de óxido.

- Limitar as taxas de rampa a menos de 10°C/min para evitar o stress térmico e prolongar a vida útil do elemento.

Como determinar se os elementos de aquecimento do forno de mufla precisam ser substituídos?

Envelhecimento ou danos no isolamento da câmara do forno

- Tijolos de isolamento ou placas de fibra cerâmica podem pulverizar-se ou fissurar após uma exposição prolongada ao calor, permitindo a fuga de calor.

- As vedações soltas da porta da fornalha criam espaços que promovem “pontos frios” através de fugas de calor.

Soluções:

- Inspecionar as paredes da câmara e as vedações das portas quanto a fissuras, substituindo-as imediatamente se necessário.

- Utilizar uma câmara de imagem térmica para identificar as áreas de fuga.

- Para operações sustentadas, substitua a camada de isolamento a cada 2-3 anos para manter a eficiência.

Envelhecimento ou desalinhamento de termopares (sensores de temperatura)

- A oxidação ou o posicionamento incorreto impede que o controlador PID detecte com precisão as temperaturas reais, desencadeando uma compensação excessiva ou insuficiente.

- Isto aparece frequentemente como leituras regulares no ecrã, apesar de as temperaturas reais do forno serem baixas.

Soluções:

- Confirme que a profundidade de inserção do termopar está de acordo com as diretrizes do fabricante (normalmente um terço no ponto médio da câmara).

- Calibrar com um termómetro padrão para garantir a precisão.

- Substituir ou recalibrar a cada 1.000 horas de funcionamento para garantir um controlo preciso.

Parâmetros de controlo PID inadequados ou falhas no módulo

- Subótimo PID (valores de P, I, D) podem causar ciclos de ultrapassagem e retrocesso ou respostas de aquecimento atrasadas.

- Módulos de controlo da temperatura degradados ou relés de corrente defeituosos prejudicam ainda mais a estabilidade do aquecimento.

Soluções:

- Executar um processo de afinação automática para repor os parâmetros PID.

- Inspecionar os relés da placa de controlo e as ligações de alimentação quanto a folgas.

- Para fornos de mufla industriais, considere a possibilidade de atualizar para um sistema de controlo PLC modular para maior fiabilidade.

Tensão de alimentação insuficiente ou maus contactos eléctricos

- A tensão de alimentação cai abaixo dos níveis nominais (por exemplo, de 380V para 360V), cortando diretamente o fornecimento de energia.

- Linhas eléctricas envelhecidas, oxidadas ou soltas introduzem flutuações de corrente.

Soluções:

- Medir a tensão de entrada e confirmar que se mantém dentro de ±5% do valor nominal.

- Aperte os parafusos dos terminais nas ligações de alimentação para fixar os contactos.

- Instale um estabilizador de tensão ou um protetor de circuito dedicado se as flutuações persistirem.

Carregamento incorreto da amostra ou fluxo de ar restrito

- Amostras demasiado compactadas ou tabuleiros que bloqueiam a circulação criam uma dispersão desigual do calor.

- A convecção limitada atrasa o aquecimento local, retardando o aumento global.

Soluções:

- Manter uma distância mínima de 2-3 cm entre as amostras e as paredes do forno para um fluxo de ar uniforme.

- Opte por tabuleiros resistentes a altas temperaturas em vez de colocar os artigos diretamente no chão.

- Para um aquecimento de grande volume, mude para designs de fornos multi-zona para otimizar a uniformidade.

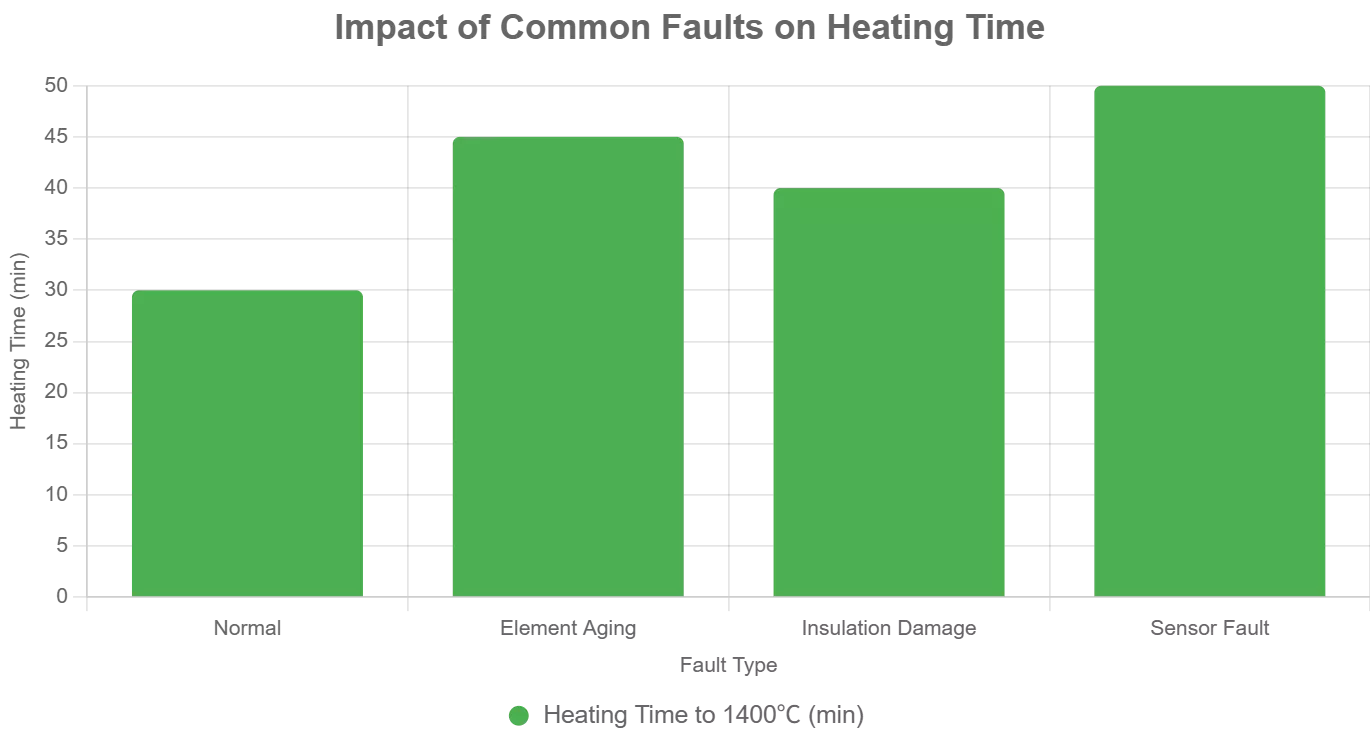

Impacto das falhas comuns no tempo de aquecimento

O diagrama abaixo ilustra como as falhas típicas afectam os tempos de rampa (com base nos dados do CVSIC):

Diagnósticos abrangentes e recomendações de manutenção

| Questão observada | Causas possíveis | Métodos de diagnóstico rápido |

| Aquecimento lento | Resistência aumentada, tensão insuficiente | Medir variações de corrente e resistência |

| Temperatura irregular | Envelhecimento de componentes, danos no isolamento | Imagem térmica do campo de calor |

| Flutuações de temperatura | Mau funcionamento do termopar ou do PID | Comparar as temperaturas reais com as temperaturas apresentadas |

| Sobreaquecimento localizado | Obstrução da amostra, fluxo de ar deficiente | Ajustar os percursos de carga e de ventilação |

Recomendações dos engenheiros do CVSIC

- Inspecionar os fornos de laboratório muito utilizados de três em três meses para obter o melhor desempenho.

- Utilize apenas elementos de aquecimento e termopares certificados pelo OEM para evitar problemas e aumentar a vida útil do equipamento.

- Se a taxa de aquecimento diminuir 15% ou mais, verificar imediatamente a potência de saída para evitar tempos de paragem.

Conclusão

A eficiência do forno de mufla depende de manutenção, e não apenas a conceção.

Comprometa-se com um calendário de manutenção regular com a CVSIC ou consulte a nossa equipa de engenharia para planos de serviço personalizados. Isto assegura um desempenho fiável e mantém os padrões de engenharia da CVSIC para uma experiência de utilizador sem falhas.

Pode ser necessário saber: