How to Choose SiC Heating Elements: A Buyer’s Guide

In high-temperature industrial settings, such as ceramic firing, metal heat treatment, or semiconductor production, Silicon Carbide Heating Elements…

Withstands up to 1650℃

30% longer service life

15+ years of manufacturing

Trusted across metallurgy, ceramics, glass, semiconductors, chemicals

stock available & custom orders in 7–30 days

CVSIC offers a comprehensive range of SiC Elements to high-temperature industrial clients worldwide, providing wholesale, customization, and OEM/ODM services to meet diverse operational requirements. Supported by consistent quality and a reliable international delivery network, we serve over 8,000 partners worldwide.

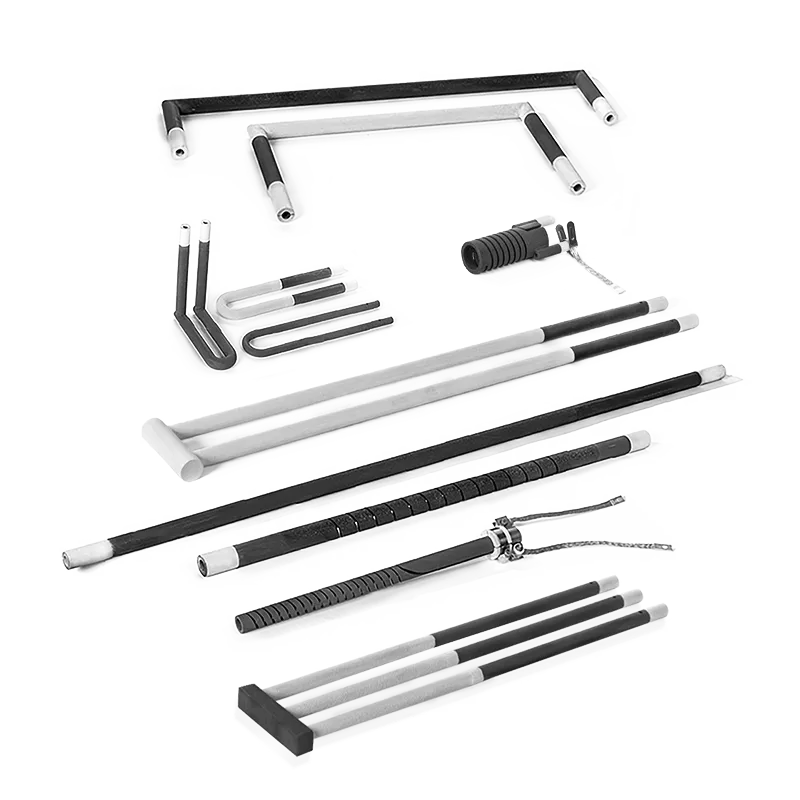

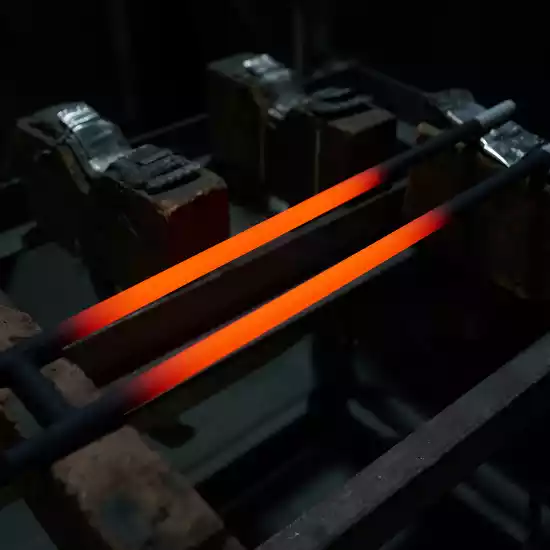

Silicon carbide heating elements, also known as silicon carbide rods, silicon carbide heaters, or silicon carbide resistors, are high-temperature electric heating elements crafted from high-purity silicon carbide.

These rods offer resistance up to 1650°C, high efficiency, long life, and energy savings, ideal for high-temperature furnaces and kilns.

Whether you require standard models or custom-specified silicon carbide heating elements, we provide a one-stop solution tailored to your needs.

As a trusted supplier of silicon carbide heating elements, we offer a full suite of B2B services to support your industrial heating needs:

Sales and Wholesale: Competitive pricing on bulk orders of SiC rods and silicon carbide bars, with flexible delivery options worldwide.

Custom Manufacturing: Partner with our engineering team to design custom SiC heating elements tailored to your furnace specifications, dimensions, and performance requirements.

Technical Support: Our experts provide guidance on element selection, installation, and maintenance to optimize performance and longevity.

Global Supply Chain: With a robust logistics network, we ensure timely delivery of silicon carbide heating rods to clients across North America, Europe, Asia, and beyond.

Solve your problems with cvsic’s powerful capabilities

Our SiC heating elements have been deployed in numerous factories and laboratories worldwide, consistently receiving positive recognition for performance and reliability.

| Comparison | Regular SiC Elements | Our SiC Heating Elements | International Brands |

|---|---|---|---|

| Temperature Range | ≤1400℃ | ≤1650℃ | ≤1650℃ |

| Service Life | Short, frequent replacement | Longer, 20–30% improvement | Stable |

| Lead Time | 30–60 days | 7–30 days | 60–90 days |

| Cost | Low but short lifespan | High cost-performance | Expensive |

| Customization | Limited | OEM/ODM, no MOQ | Limited |

Cost-Effective Alternative to Imported Products, combining quality and delivery advantages.

Selecting the appropriate silicon carbide heating element can enhance industrial processes. Our team provides comprehensive guidance to help identify the optimal silicon carbide rods or strips, ensuring suitability for specific applications. Whether upgrading an existing system or designing a new one, our silicon carbide heating elements offer the reliability and performance required for competitiveness.

Under normal operating conditions, silicon carbide heating elements typically last between 3,000 and 5,000 hours. The exact lifespan depends on various factors, including operating temperature, furnace atmosphere, heating method, and maintenance practices. For instance, operation in an oxidizing atmosphere extends lifespan, while reducing atmospheres or frequent start-stop cycles may shorten it. Proper installation and regular maintenance can significantly prolong service life.

We impose no MOQ restrictions and support single-unit sample orders, facilitating laboratory testing or small-batch trials. For bulk purchases, we offer competitive pricing and flexible delivery options.

Yes. Our SiC heating elements are fully compatible with international brands, such as Kanthal and Globar, in terms of specifications, mounting dimensions, and electrical performance, allowing for direct replacement without requiring modifications to the furnace. Leveraging in-house R&D and process optimization, we provide superior cost-effectiveness and faster delivery times.

Standard configurations (straight, U-shaped, W-shaped) are kept in stock for immediate dispatch. For custom, non-standard products, the production cycle ranges from 7 to 30 days, depending on the specifications and quantity. With a reliable supply chain and logistics network, we ensure rapid delivery to clients worldwide.

Yes. We offer comprehensive installation manuals, wiring guides, and usage precautions, along with remote video technical support upon request. For large-scale projects, we can arrange on-site guidance from our engineering team to ensure proper installation and safe operation of the heating elements.

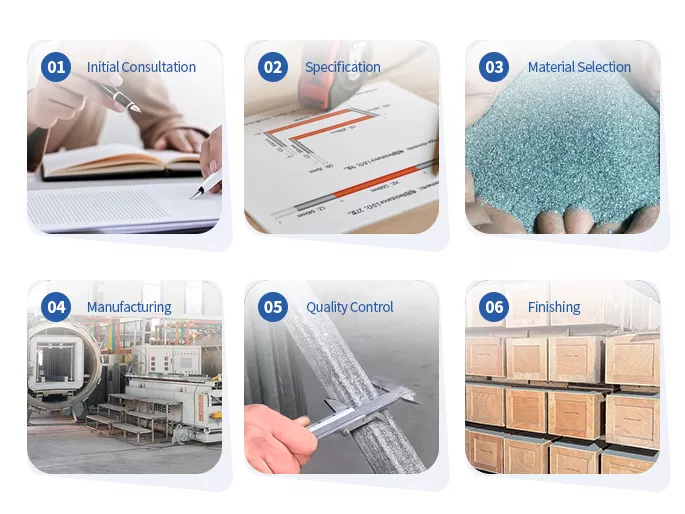

Each silicon carbide heating element undergoes rigorous inspection of raw materials, high-temperature sintering tests, resistance verification, and final quality checks, ensuring compliance with international standards. With over 8,000 global clients, our products have earned long-term validation for stability and consistency.

In high-temperature industrial settings, such as ceramic firing, metal heat treatment, or semiconductor production, Silicon Carbide Heating Elements…

In high-temperature industrial settings, whether it’s ceramic firing, metal heat treatment, or semiconductor crystal growth, Silicon Carbide Heating…

Imagine a high-temperature industrial setting: a ceramic plant’s tunnel kiln operating 24/7, a semiconductor production line requiring precise…

In high-temperature industrial settings, whether it’s kiln firing in ceramic factories, semiconductor crystal growth, or new energy battery…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support