Applications for Custom Solutions

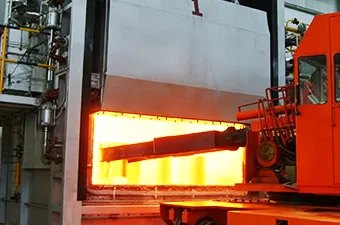

- Research Furnaces: Ideal for small-scale experiments and non-standard furnace designs

- Ceramics & Glass: Specialty kilns, transparent ceramics, and optical glass processing

- Metallurgical Heat Treatment: Special alloys, powder metallurgy, and vacuum heat treatment

- Semiconductor & Chemical Industries: Custom diffusion furnaces, crystal growth systems, and high-temperature reactors

CVSIC vs. Other Suppliers

| Comparison Item |

Standard Manufacturers |

CVSIC Customization Services |

International Premium Brands |

| Customization Capability |

Limited options |

Comprehensive shape, parameter, and condition support |

Restricted |

| Technical Support |

Basic production |

Dedicated engineer-led optimization |

Limited |

| Delivery Time |

30–60 days |

7–30 days |

60–90 days |

| Cost |

Low cost, short lifespan |

Cost-effective, near-premium quality |

Expensive |

| Minimum Order Quantity |

Often required |

No MOQ, sample-friendly |

Typically restricted |

Optimize Your High-Temperature Industrial Processes

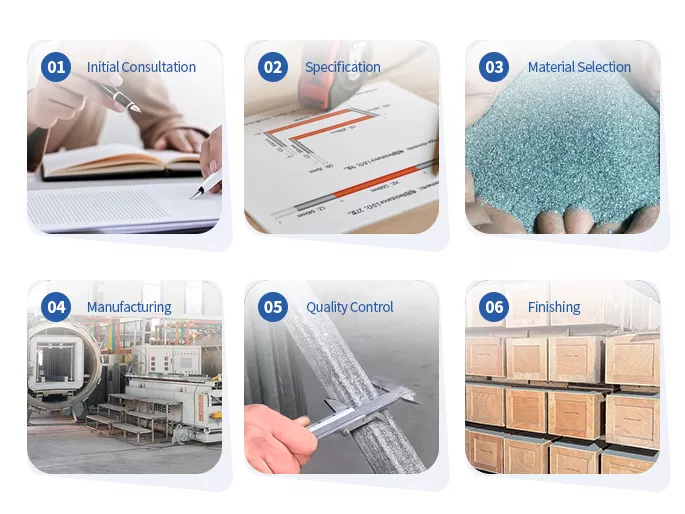

Choosing the right custom heating element is key to boosting process efficiency. Our team will assist with design and selection to ensure specialty SiC or MoSi2 elements perfectly match your furnace and process. Whether optimizing existing systems or developing new equipment, our custom high-temperature furnace elements provide stable, efficient heating performance, giving you a competitive edge.

Contact Us for Your Custom Heating Element Solution

Ready to enhance your high-temperature processes with custom Silicon Carbide or Molybdenum Disilicide heating elements? Contact our team today for quotes, product details, or custom consultation. We’re dedicated to powering your success with world-class custom SiC and MoSi2 heaters and expert service.

FAQ

Can you customize without drawings, only furnace dimensions?

Yes, simply provide furnace dimensions, operating temperature, atmosphere, and power requirements, and our engineers will design a tailored solution.

What is the lead time for custom products?

Typically 7–30 days, depending on design complexity and order volume.

Are custom elements expensive?

No, our custom elements deliver performance and longevity comparable to premium brands at a more competitive price and faster delivery.

Are they compatible with brands like Kanthal or Globar?

Yes, our custom elements match the installation dimensions and electrical performance of brands like Kanthal and Globar for seamless replacement.

Do you offer technical support?

Absolutely, we provide detailed installation guides, wiring instructions, and optional remote or on-site support for your project.

Standard Elements Fall Short? Let CVSIC Build Your Custom Solution.