Debinding Furnace

CVSIC offers comprehensive debinding furnace systems, enhancing your production efficiency from design to ongoing support.

Our debinding furnaces are utilized in both industry and research, offering vacuum, hydrogen, and hot air flow, as well as high-temperature heating capabilities. They effectively help with removing binders and preparing materials from lab work to large-scale production.

CVSIC debinding furnaces operate at temperatures ranging from 600°C to 1700°C and utilize various heating elements, including graphite rods and metal wires. They use common gases such as nitrogen, argon, and hydrogen, ensuring that operations remain clean and stable with a wide range of materials.

Best Debinding Furnace Manufacturer & Supplier In China

In ceramics, powder metallurgy, additive manufacturing, and materials research, effective binder removal is critical to achieving high-quality end products.

CVSIC’s debinding furnaces, with a temperature range of 600–1700°C, feature models that support vacuum, hydrogen, and hot air capabilities, enabling efficient, contaminant-free degreasing for ceramics, powder metallurgy, additive manufacturing, and research applications.

Why Choose Our Debinding Furnaces?

- Superior Product Quality: Thorough binder removal prevents cracks, voids, or impurities during sintering, ensuring flawless results.

- Enhanced Process Stability: Precise atmosphere and temperature control guarantee consistent batch-to-batch performance.

- Versatile Industry Applications: Reliable support for applications ranging from laboratory research to large-scale industrial production.

CVSIC Debinding furnace Features

- Precision Thermal Control: Multi-zone temperature control keeps heat steady within ±1°C, avoiding overheating.

- Flexible Atmosphere Options: Supports nitrogen, argon, hydrogen, and more to meet diverse binder decomposition needs.

- Robust and Durable Design: Constructed with high-quality ceramic fiber and alumina for long-lasting performance.

- Energy Efficiency: Advanced insulation and heating systems reduce energy usage by 15–25% and minimize operating costs.

- Safety and Compliance: Our furnaces meet CE and ISO safety rules and have built-in monitors for temperature and gas safety.

Buy High-Quality Debinding Furnace from China

Quick Navigation

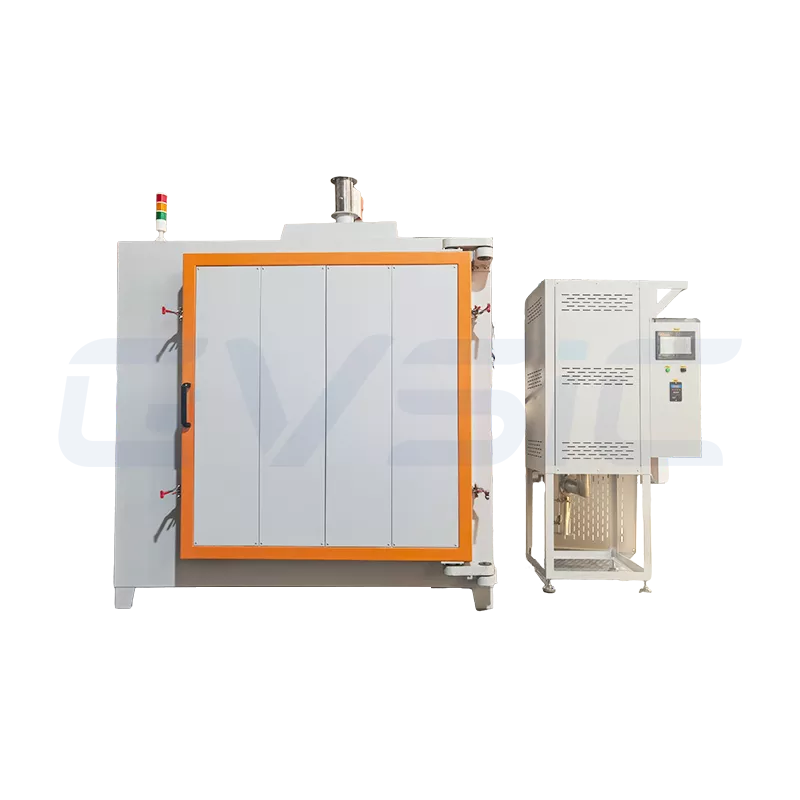

Hot Air Circulation Debinding Furnace

- Name: Hot Air Circulation Debinding Furnace

- Furnace Chamber: Stainless Steel Chamber

- Heating Element: Resistance Wire

- Maximum Temperature: 650°C

- Operating Temperature: 600°C

- Vacuum Level: Non-Vacuum

- Available Atmosphere: Inert Atmosphere (N₂, CO₂, Ar₂, etc.)

- Application Processes: Sintering, Debinding Sintering, Heat Treatment

Debinding and Pre-Sintering Integrated Furnace

- Name: Debinding and Pre-Sintering Integrated Furnace

- Furnace Chamber: Ceramic Fiber

- Heating Elements: Resistance Wire, SiC Heating Elements

- Maximum Temperature: 650°C, 1200°C

- Voltage: 380V

- Vacuum System: None

- Available Atmosphere: Inert atmosphere (N₂, CO₂, Ar₂, etc.)

- Process Applications: Sintering, Brazing, Debinding Sintering, Heat Treatment, Annealing

Lifting Atmosphere Sintering Furnace

- Name: Atmosphere debinding and sintering furnace

- Furnace chamber: Ceramic fiber

- Heating elements: MoSi2 heating elements

- Maximum temperature: 1700°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Available Atmosphere: Inert Gas (N₂, CO₂, Ar₂)

- Applications: Degreasing Sintering, Heat Treatment

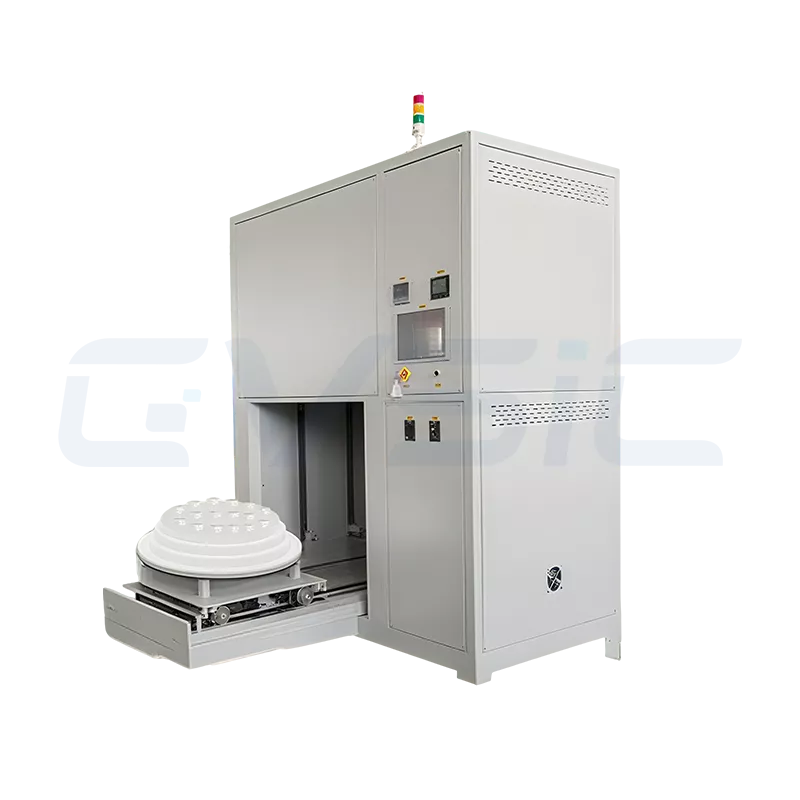

Bottom Loading Debinding and Sintering Furnace

- Name: Degreasing and Sintering Furnace

- Furnace Lining: Ceramic Fiber

- Heating Elements: MoSi2 Heating Elements

- Maximum Temperature: 1750°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Process Applications: Degreasing Sintering, Heat Treatment

- Brand: CVSIC

Hydrogen Furnace

- Name: Hydrogen Sintering Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With maximum working temperature 1600℃

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

CVSIC Debinding Furnace Services

We provide end-to-end solutions to meet your debinding furnace requirements:

- Global Sales and Wholesale: Competitively priced finished furnaces with rapid delivery and OEM branding options.

- OEM Branding: Our furnaces can be customized to align with your brand and product portfolio.

- Custom Design: We can make furnaces to fit your needs, like changing the size, gas control, or heating settings.

- Professional Installation: Expert technicians ensure seamless on-site setup and commissioning.

- Technical Support and Maintenance: 24/7 support, spare parts, and preventive maintenance maximize uptime and performance.

- End-to-End Project Management: From initial consultation to post-installation support, we deliver streamlined services for both standard and custom solutions.

Why Choose CVSIC?

Solve your problems with cvsic’s powerful capabilities

Production Capacity

Quality Control

Quick Support

Global Partnership

CVSIC Debinding furnaces Applications Across Industries

- Ceramics Manufacturing: Ensures defect-free sintering by removing binders from ceramic components.

- Metallurgy: Facilitates debindingof metal powders and components in powder metallurgy processes.

- Additive Manufacturing: Supports pre-sintering binder removal for 3D-printed metal and ceramic parts.

- Materials Science: Enables preparation of advanced materials for research and industrial applications.

- Automotive and Aerospace: Provides clean surface treatment for precision components prior to heat treatment.

- Research Laboratories: Offers controlled debindingfor material testing and development.

FAQ

Do you offer OEM branding for debinding furnaces?

Yes, we offer customization options for our furnaces, enabling seamless integration with your brand and product line.

What is the delivery time for finished debinding furnaces?

Our standard furnaces are delivered within 2–4 weeks, depending on location and order volume, through our efficient global logistics.

Can you customize furnaces for specific binder removal processes?

Absolutely, we offer custom furnaces with tailored chamber sizes, atmosphere controls, and thermal profiles, typically delivered in 8–12 weeks.

How energy-efficient are your debinding furnaces?

Our furnaces utilize ceramic fiber insulation and intelligent heating to conserve energy and reduce costs, while maintaining effective material cleaning.

What support is available after purchasing a debinding furnace?

We offer 24/7 technical support, spare parts, and maintenance services, with dedicated account managers to ensure sustained reliability and performance.

Why Partner with CVSIC for debinding Furnaces?

Partner with CVSIC for efficient, precise debinding furnaces—customized solutions, fast delivery, and expert support for your needs worldwide. Contact us for OEM branding, wholesale, or a consultation.

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support