Electric Heating Elements

The Cleanest, Most Controllable, and Sustainable Way to Heat in Industrial Systems

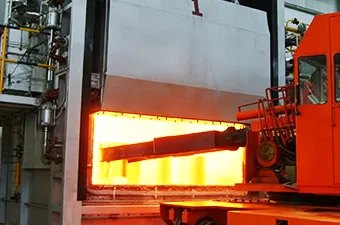

Electric heating elements are the key components in industrial heating systems that turn electricity directly into heat. They’re used all over the place—in industrial furnaces, heat-treatment setups, ceramic and powder-sintering furnaces, lab furnaces, and tons of OEM heating gear.

Compared to gas or liquid heating, electric has huge perks: no direct emissions, super-precise temperature control, and a much simpler system. That’s why it’s becoming a big deal in modern industrial heating.

What Are Electric Heating Elements?

From an engineering perspective, they’re components that operate on the principle of resistive heating: Current flows through a resistive material, converting electrical energy directly into heat, which then spreads via radiation, conduction, or convection.

Their main performance comes down to the material system, including stuff like:

- Max operating temperature

- Resistance stability

- How well it handles oxidation and different atmospheres

- Overall lifespan

Basic Working Principle of Electric Heating Elements

It boils down to three key steps:

- Power input: Setting voltage, current, and power levels

- The resistive material heats up: Resistance determines how efficiently it generates heat.

- Heat output: Hits your target temp and keeps things evenly heated

In real-world industrial use, it’s the combination of material choice, element shape, and power density design that determines whether your system stays stable and reliable, and runs long-term.

Main Ways to Classify Electric Heating Elements

I. By Material System (The Most Important)

Different materials set the temperature ceilings, lifespan, and where they shine.

| Material System | Max Operating Temp | Applicable Atmosphere | Key Features | Typical Applications |

|---|---|---|---|---|

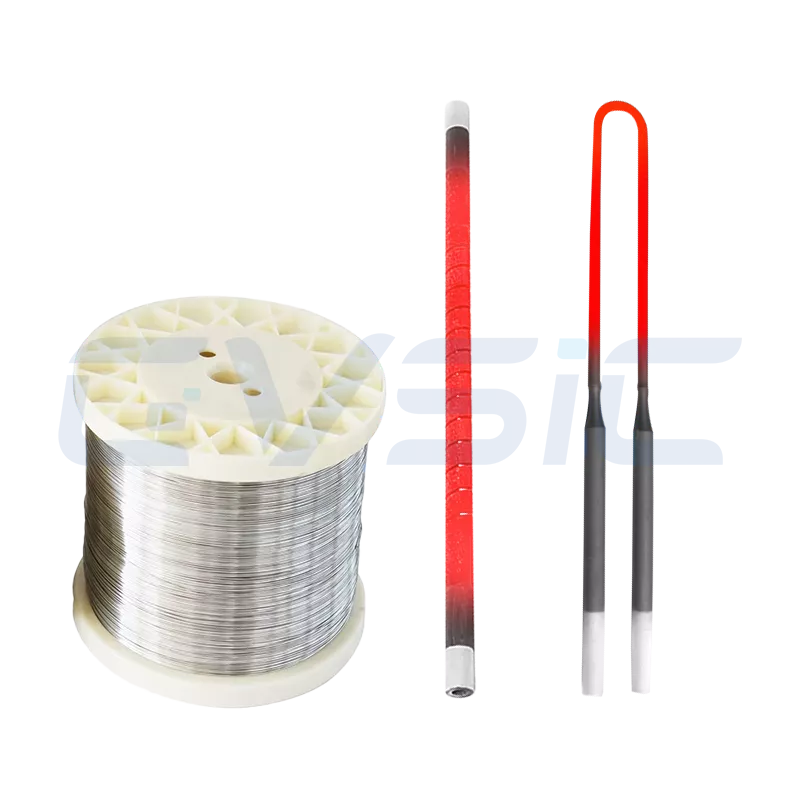

| Resistance Wire (FeCrAl / NiCr / NiCu) | ≤1400°C | Oxidizing / Neutral | Stable resistance, flexible designs | Industrial furnaces, ovens |

| Silicon Carbide Elements | ≤1600°C | Oxidizing | High temp strength, long lifespan | Industrial furnaces, ceramic kilns |

| MoSi2 Heating Elements | ≤1800°C | Oxidizing | Extreme high temps, strong oxidation resistance | Sintering furnaces, lab furnaces |

II. By Structure Form

We design them in various shapes based on your equipment and setup:

- Wire or coil: Standard for resistance wire systems

- Rod-shaped: Typical for SiC and MoSi₂ elements

- Strip or plate: Great for specific modules

Shape isn’t picked alone—it’s tailored to your setup and mechanical constraints.

III. By Temperature Range

| Temperature Range | Common Materials |

|---|---|

| ≤600°C | NiCu resistance alloy |

| 600–1200°C | NiCr resistance wire |

| 1000–1400°C | FeCrAl resistance wire |

| 1400–1600°C | SiC Heating Elements |

| ≥1600°C | MoSi2 Heating Elements |

Electric vs Gas vs Liquid Heating

Key Comparison of Industrial Heating Methods

| Aspect | Electric Heating | Gas Heating | Liquid Heating |

|---|---|---|---|

| Energy Source | Electricity | Natural gas / Fuel | Heat transfer oil / Steam |

| Direct Emissions | None | Yes (CO₂ / NOx) | None |

| Temperature Control | Precise and quick | Somewhat rough | Medium |

| Efficiency | High—direct delivery | Big heat losses | Some transfer losses |

| System Complexity | Simple | Complex | Complex |

| Safety | No open flame | Explosion risk | Leak risk |

| Automation Friendly | Top-notch | Okay | Okay |

| Sustainability | Very high | Fossil fuel dependent | Varies by source |

Why Industries Are Switching to Electric Heating

Zero Pollution or Byproducts

No CO₂, NOx, or burn leftovers—keeps your furnace atmosphere steady, ideal for precise treatments or high-purity sintering.

Highly Controllable Temp and Power

Easy fine-tuning, multi-zone control, and fast response—boosts process consistency and quality.

Safer and Lower Maintenance

Ditch gas lines and burners for a simpler setup and lower long-term maintenance costs.

Fits Electrification and Green Trends

Works great with renewables, key for cutting carbon and sustainable manufacturing.

Gas or liquid still has its place in low-temp or massive-load scenarios, but for high-temp, precision, or super-clean jobs, electric is the smarter long-term choice.

Choosing Elements for Different Applications

Industrial Furnaces & Heat Treatment

Ceramic & Powder Sintering

Lab & Research Furnaces

- Temp Range: 1000–1800°C

- Go-To Materials: MoSi2

- Main Focus: Even temps, spot-on control

Key Performance Specs for Industrial Electric Elements

These matter big time for reliability when selecting or designing:

- Max Operating Temperature (°C)

- Power Density (W/cm²)

- Resistance Stability

- Service Life

- Atmosphere Compatibility

- Thermal Cycling Tolerance

They often involve trade-offs, so judge based on your actual setup.

Standard vs Custom Electric Heating Elements

| Aspect | Standard Elements | Custom Elements |

|---|---|---|

| Fit | One-size-fits-most | Tailored to your conditions |

| Lifespan Stability | Decent | Way better |

| Upfront Cost | Cheaper | A bit more |

| Long-Term Cost | Hit or miss | More predictable |

| Engineering Risk | Higher | Lower |

For tricky conditions, high temps, or nonstop use, custom delivers real engineering wins.

FAQ

Are your electric heating elements all standard inventory?

Not quite. We’ve got both off-the-shelf standards and fully custom options tailored to your specific conditions. For high-temp, special atmospheres, or long runs, we usually suggest going custom based on your real parameters.

How to choose between SiC and MoSi2 elements?

Key things to consider:

- Your target max temp

- Running near the limit long-term?

- Lifespan and how often you want to replace

Rule of thumb:

- Up to 1600°C, wanting solid reliability and good value → SiC

- Over 1600°C, extreme apps → MoSi₂

Can resistance wire replace SiC or MoSi2?

Yeah, in mid-to-low temperatures (≤1400°C), FeCrAl or NiCr wire is more flexible and easier on the budget.

But above 1400°C, long-term? We don’t recommend swapping it in for SiC or MoSi2.

Can you design elements around my existing furnace structure?

Absolutely. A lot of our custom jobs start with your current furnace size, mounting setup, and power—we design to fit perfectly, no need to overhaul your whole system.

Do you only offer one type of heating material?

Nope. We can help mix and match different types in the same system to cover varying temp zones or process steps.

Contact Us | Get Your Electric Heating Solution

Stable heating starts with the right elements.

If you’re:

- Designing or upgrading furnaces/equipment

- Dealing with short element lifespans

- Needing tailored solutions for your setup

- Hunting for a solid B2B supplier

Drop us your details and needs—we’re ready to talk shop.

We can help:

- Check if your current setup makes sense.

- Suggest the best materials and shapes.

- Deliver custom plans and volume supply.

Engineering outcomes are often locked in at the selection phase.

We’re all about teaming up early to nail it right from the start.