Furnace Heating Elements

Tailored Selection and Custom Solutions for Industrial Furnace Heating Systems—Electric Heating Element Setup and Engineering Support for Industrial Furnaces, Heat Treatment Furnaces, Sintering Furnaces, and High-Temp Lab Furnaces.

- Match your furnace type and conditions for rock-solid heating stability

- Boost element lifespan and cut down on maintenance costs

- Full customization and reliable long-term supply for all your B2B needs

Key Attributes of Furnace Heating Elements

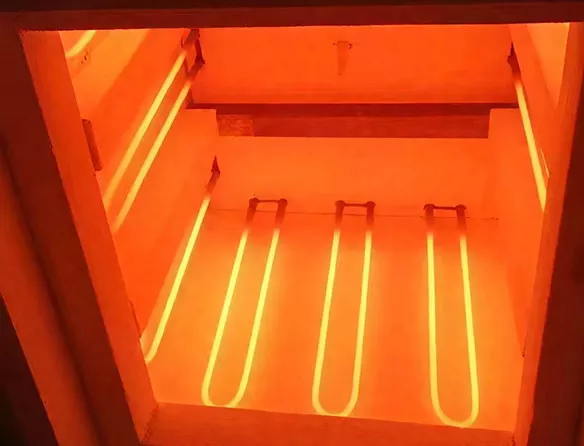

These are the core heating parts designed specifically for industrial furnaces—their performance has a direct impact on temp evenness, lifespan under repeated heating/cooling cycles, and overall process reliability.

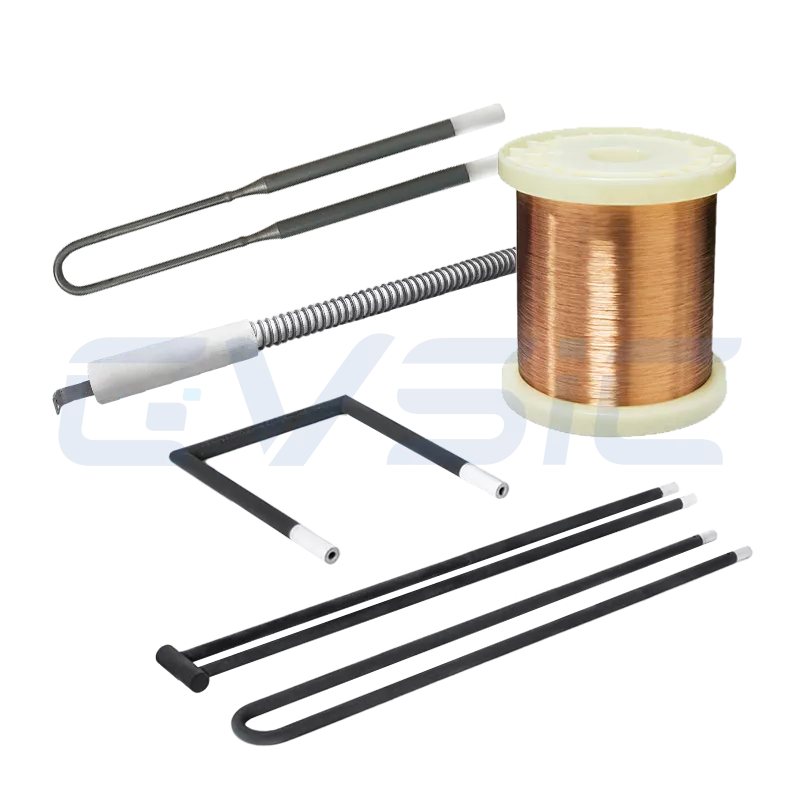

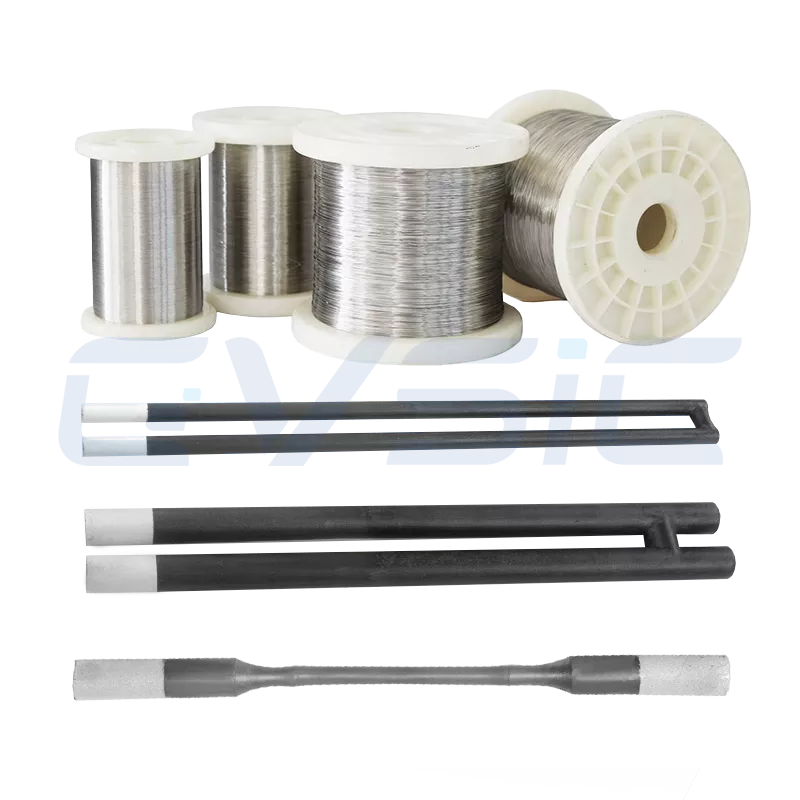

- Material Systems: SiC, MoSi2, FeCrAl, NiCr

- Temp Adaptation Range: Medium (≤1200°C), High (1200–1600°C), Ultra-High (≥1600°C)

- Shapes: Rod, U-shaped, spiral, plate, custom resistance wire

- Typical Uses: Heat treatment furnaces, sintering furnaces, lab furnaces

- Engineering Priorities: How well it fits the system, installation setup, cold-end design, atmosphere compatibility

Key Features:

- Handles long-term high-temps: Tough enough for multiple thermal cycles and constant power

- System fit: Designed to work hand-in-hand with your furnace lining, structure, power supply, and atmosphere

- Real-world reliability: Material, power load, and installation directly control how long it lasts

Note: Furnace heating elements aren’t like general-purpose ones—they’re engineered specifically for industrial furnace setups.

What We Offer for Furnace Heating Elements

Wholesale and steady long-term supply: SiC Elements, MoSi2 Elements, FeCrAl, NiCr

Custom solutions:

- Matching your exact furnace type

- Temp range and power design

- Special shapes (U-type, spiral, plate)

Project/OEM partnerships:

- In-depth engineering discussions

- Tight batch consistency and quality checks

Supporting extras:

- Cold-end wiring, fixtures, insulation

- Full optimization of your furnace heating system

Heating Needs by Furnace Type

Heat Treatment Furnace Elements

Sintering / High-Temp Furnace Elements

Lab / Special Process Furnace Elements

- Features: Compact size, precise temp control, quick heat response

- Common Materials: MoSi, custom resistance wire

- Focus Areas: Temp accuracy, reliability through thermal cycles

- Common Apps: Research experiments, high-precision heat treating, small high-temp furnaces

Selection Furnace Heating Elements by Temp Range

| Temp Range | Typical Furnace Type | Go-To Elements | Engineering Focus |

|---|---|---|---|

| ≤1200°C | Heat treatment furnace | FeCrAl, NiCr | Power stability, maximizing lifespan |

| 1200–1600°C | Medium-high temp furnace | SiC Heating Elements | Oxidation resistance at high temps, even zoning |

| ≥1600°C | Ultra-high temp furnace | MoSi2 Heating Elements | Lifespan at extreme temps, managing thermal shock |

Impact of Furnace Environment on Heating Elements

Key Factors:

- Atmosphere: Air, inert, reducing, or vacuum

- Lining Materials: Refractory bricks, ceramic fiber, composites

- Installation Styles: Straight insert, U-shaped, spiral, plate

- Power Modes: AC/DC, intermittent/continuous

Heads up: Around 80% of element failures come from environment or installation mismatches—not the material itself.

Electric Furnace Heating vs Gas / Liquid Heating

| Aspect | Electric (Furnace) | Gas Heating | Liquid Heating |

|---|---|---|---|

| Energy Cleanliness | No burn, zero pollution | Emissions produced | Leak risks |

| Temp Control Precision | Very high | Medium | Medium |

| System Complexity | Medium | High | High |

| Sustainability | Very high | Low | Medium |

| Service Life | Long | Medium | Medium |

Bottom line: Electric heating elements are the future for industrial furnaces—especially great for high-temp and precision control jobs.

FAQ

Why do in-furnace elements fail early? What’s usual?

Usually it’s a mismatch with the environment, poor installation, or overloading power—not faulty material.

Can you replace elements in my existing furnace?

Yep, we offer adaptation plans to make sure new ones fit perfectly with your current setup.

How to combine SiC and MoSi2 in a furnace?

Use SiC for medium-high zones and MoSi₂ for the hottest parts—gets you stable long-term performance.

Do you do non-standard customs?

Absolutely—we customize based on your furnace size, power, voltage, and other specs.

Can resistance wire swap in for SiC or MoSi₂?

For medium-low temps, sure—FeCrAl or NiCr works. But over 1400°C? Stick with SiC or MoSi₂.

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support