MoSi2 Heating Elements: Introduction and Applications

Imagine you’re running a ceramic factory where the tunnel kiln must operate steadily at 1450°C, and any downtime…

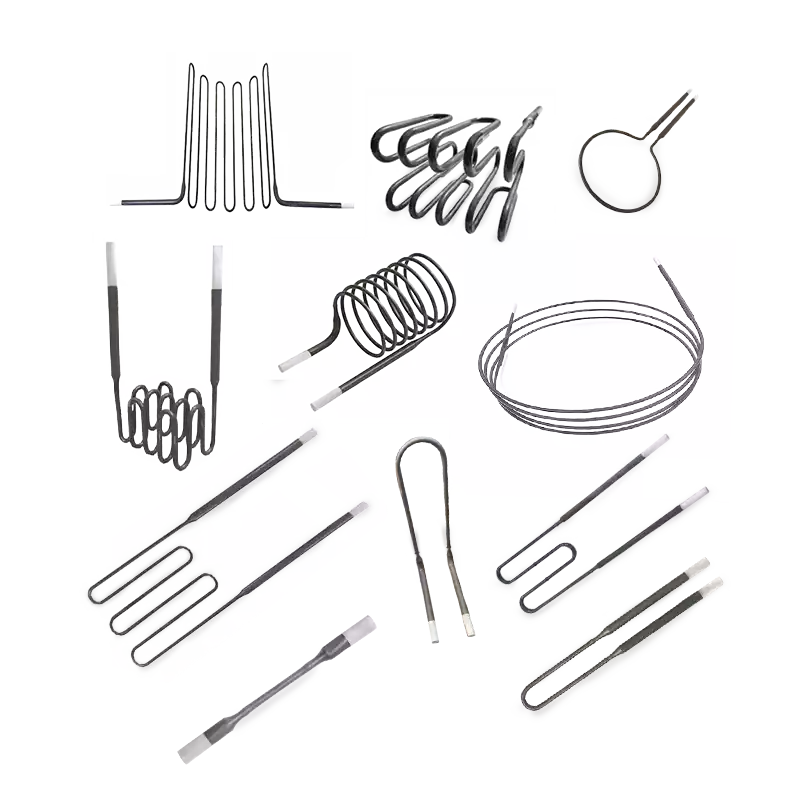

MoSi2 heating elements, commonly referred to as MoSi2 rods, or MoSi2 heaters, are advanced ceramic heating components crafted from high-purity molybdenum disilicide.

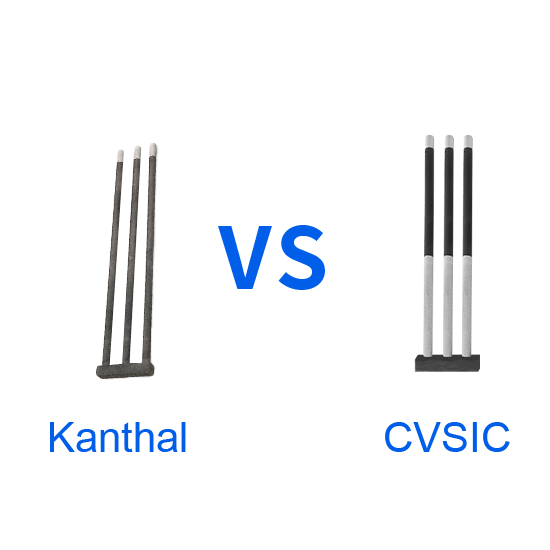

Compared to silicon carbide heating elements, MoSi2 Heating rods offer superior temperature (up to 1850℃) and oxidation resistance, as well as stability at elevated temperatures, making them ideal for ultra-high temperature processes.

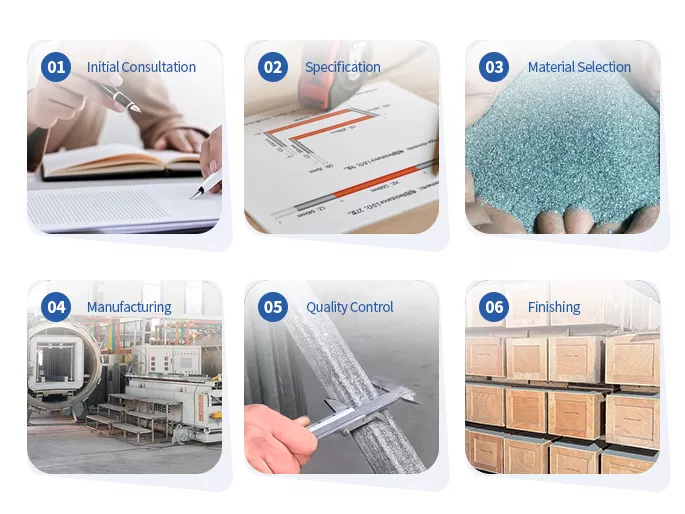

As a professional molybdenum disilicide heating element supplier, we offer comprehensive B2B services for global high-temperature industrial clients:

Solve your problems with cvsic’s powerful capabilities

Our reliable and versatile MoSi2 heaters are widely used in these industries:

Our MoSi2 heating elements are a trusted solution in high-temperature laboratories, university centers, and industrial environments worldwide.

| Feature | Regular MoSi2 Elements | CVSIC MoSi2 Elements | Imported Brands |

|---|---|---|---|

| Max Temp | ≤1700℃ | ≤1850℃ | ≤1850℃ |

| Lifetime | Short, frequent replacement | 20–50% longer | Stable |

| Resistance Stability | Poor at high temp | Excellent, precise control | Excellent |

| Lead Time | 30–60 days | 7–30 days | 60–90 days |

| Cost | Low but unstable | Best price-performance | High |

| Customization | Limited | OEM/ODM, no MOQ | Limited |

A cost-effective alternative to premium brands like Kanthal Super and Kyocera MoSi₂, offering comparable performance with faster delivery.

Selecting the right MoSi₂ heating elements can significantly enhance the performance and reliability of ultra-high-temperature furnaces. Whether upgrading existing systems or designing new high-temperature solutions, our expert engineering team provides personalized support—from product selection to installation and operation—ensuring you achieve optimal heating performance.

In oxidizing atmospheres at 1600–1700°C, our elements generally last 4,000–8,000 hours. Lifespan depends on furnace atmosphere, operating temperature, and cycling frequency, lasting longer in oxidizing conditions and decreasing in vacuum or reducing environments.

No minimum order. Single-unit samples available for research and testing. Bulk orders benefit from competitive pricing and flexible delivery.

MoSi₂ elements meet the electrical and dimensional specifications of leading brands such as Kanthal Super. This allows for direct replacement without furnace modifications, along with the benefits of expedited delivery and cost-effectiveness.

Standard configurations ship immediately. Custom designs delivered within 7–30 days.

Yes, we provide comprehensive installation manuals, wiring instructions, and usage guidelines to ensure a seamless setup. For large projects, we offer remote or on-site technical support.

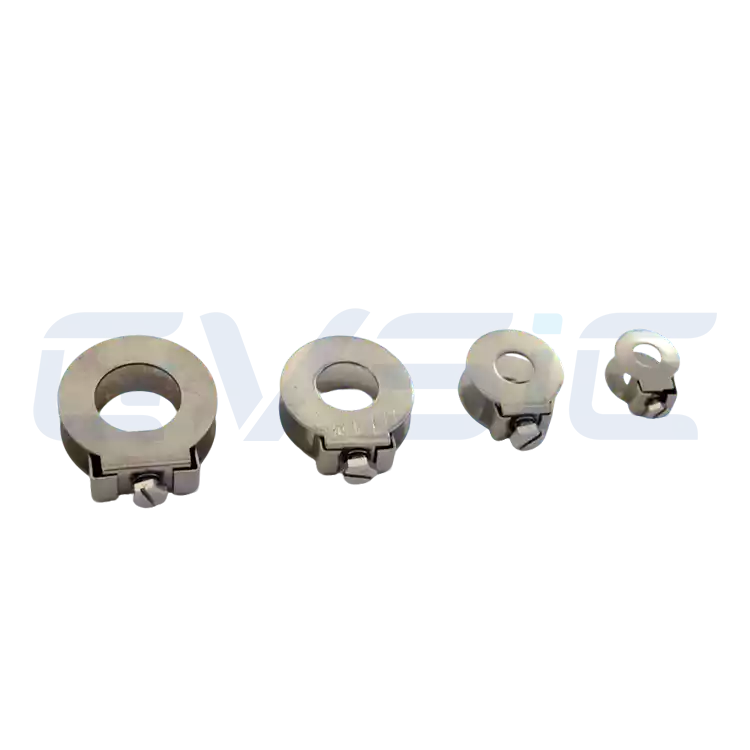

MoSi₂ is a brittle ceramic material; however, our customized wooden crates and individual foam packaging ensure safe delivery, with a breakage rate of less than 0.1%.

Yes, we offer OEM/ODM services, designing elements to match your furnace type, voltage, current, and other specifications. We also provide optimization support to enhance energy efficiency and lifespan.

Imagine you’re running a ceramic factory where the tunnel kiln must operate steadily at 1450°C, and any downtime…

In high-temperature industrial settings, whether it’s kiln firing in ceramic factories, semiconductor crystal growth, or new energy battery…

Imagine you’re running a ceramic factory where the kiln must operate continuously at 1700°C, and any failure of…

In the realm of high-temperature industrial heating, silicon carbide and molybdenum disilicide heating elements are the primary materials…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support