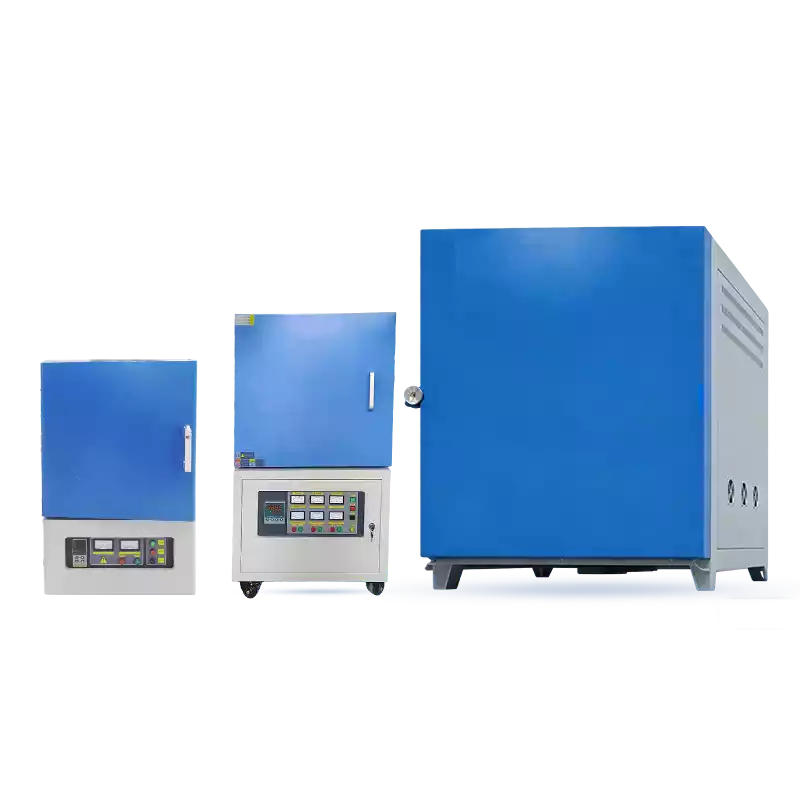

1400°C Muffle Furnaces

1400°C muffle furnace is a premier high-temperature solution for industrial heat treatment and scientific research, boasting a maximum temperature of 1400°C and offering multi-specification customization with volumes ranging from 1 to 100L and powers ranging from 1 to 120kW. It caters to the batch production demands of industries like metallurgy, ceramics, powder metallurgy, electronics, and new material development, while also supporting small-scale heat treatment testing in laboratories.

CVSIC delivers comprehensive solutions—from standard models to bespoke customization—at affordable prices. Our end-to-end services encompass design, manufacturing, installation, commissioning, after-sales support, and technical training. We empower enterprises to significantly enhance heat treatment efficiency, reduce energy consumption, and ensure process stability.

1400°C Muffle Furnace Manufacturer and Supplier

Procure high-performance 1400°C muffle furnaces directly from a reputable manufacturer in China, ensuring products tailored to specific technical requirements at competitive prices. We serve global B2B clients with comprehensive services including sales, wholesale, OEM branding, custom design, professional installation, and round-the-clock technical support, to guarantee seamless integration and operational excellence.

CVSIC 1400°C Muffle Furnace Features

- High-Temperature Stability: Maximum operating temperature of 1400°C, supporting continuous high-temperature operation.

- Flexible Volume Options: 1–100L, ideal for transitioning from laboratory research to industrial production.

- Power Versatility: 1–120kW, tailored to diverse process and capacity requirements.

- Premium Heating Elements: Features silicon carbide (SiC) heating elements for exceptional heat resistance and longevity.

- Precise Temperature Control: Intelligent PID controller with programmable multi-segment temperature curves, achieving ±1°C accuracy.

- Efficient Insulation: Composite ceramic fiber and alumina insulation for maximum energy efficiency.

- Safety Design: Includes over-temperature protection, power-off safeguards, automatic alarms, and interlock systems.

- Extendable Functionality: Options for atmosphere control, data logging, automatic loading, and remote monitoring.

Buy High-Quality 1400°C Muffle Furnace from China

Quick Navigation

1400°C Large Muffle Furnace

- Name: CVSIC 1400°C Large Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

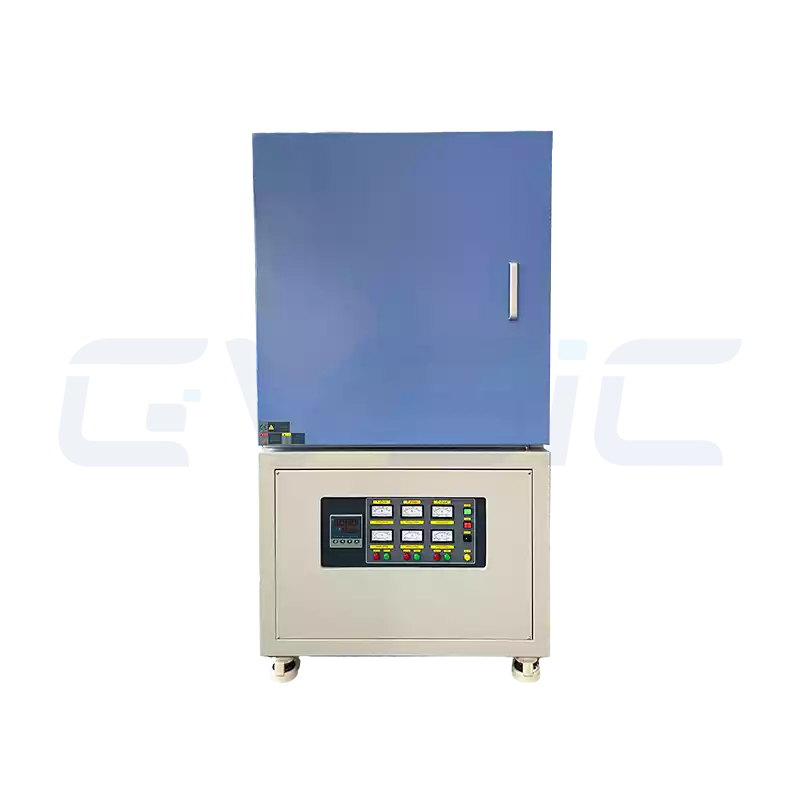

1400°C Medium Muffle Furnace

- Name: CVSIC 1400°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1400°C Small Muffle Furnace

- Name: CVSIC 1400°C Small Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

CVSIC 1400°C High-Temperature Industrial Muffle Box Furnace Customization Service

We are committed to providing comprehensive industrial heat treatment solutions in addition to manufacturing high-quality equipment.

- Customized Design: Fully customizable chamber size, volume, power, and atmosphere control systems.

- OEM/ODM Services: Offers brand customization and technology licensing.

- Installation and Commissioning: Global on-site installation and remote debugging support.

- Training and Technical Support: One-on-one engineer training to ensure optimal equipment performance.

- Maintenance and Spare Parts: Long-term supply of heating elements and consumables to minimize maintenance costs.

Why Choose CVSIC?

Solve your problems with cvsic’s powerful capabilities

Production Capacity

Quality Control

Quick Support

Global Partnership

1400°C Muffle Furnace Application

- Metallurgy and Powder Metallurgy: Ideal for metal sintering, annealing, and heat treatment to enhance material density and strength.

- Ceramics and Refractory Materials: Perfect for high-performance ceramics, electronic ceramics, and advanced materials’ high-temperature sintering.

- Laboratory and Scientific Research: Supports research institutes and universities in new material development, heat treatment experiments, and performance testing.

- Electronics and Semiconductor Industry: Used for annealing, oxidation, and protective atmosphere processing of components.

- Glass and New Material Development: Facilitates glass softening, sealing, and high-temperature experimentation for innovative new materials.

FAQ

What is the difference between a 1400°C muffle furnace and a 1200°C muffle furnace?

The 1400°C muffle furnace utilizes high-performance heating elements (SiC), capable of withstanding higher temperatures for demanding industrial processes, such as ceramics and special metal sintering. The 1200°C model is suited for standard heat treatment and experimental applications.

Can the 1400°C muffle furnace be used with a protective atmosphere?

Yes, we can integrate atmosphere control systems (e.g., nitrogen, argon, reducing gases) to meet oxygen-free or reducing atmosphere requirements.

Does it support non-standard customization?

Yes, we can tailor chamber size, power, atmosphere control, and automation features to your specific process needs.

How long is the equipment delivery cycle?

Finished furnaces typically ship within 2 to 4 weeks, while custom muffle furnaces may take 8 to 14 weeks, depending on your location and the volume of your order.

What does after-sales service include?

We offer remote technical guidance, on-site installation and commissioning, training, and long-term spare parts supply and maintenance services.

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support