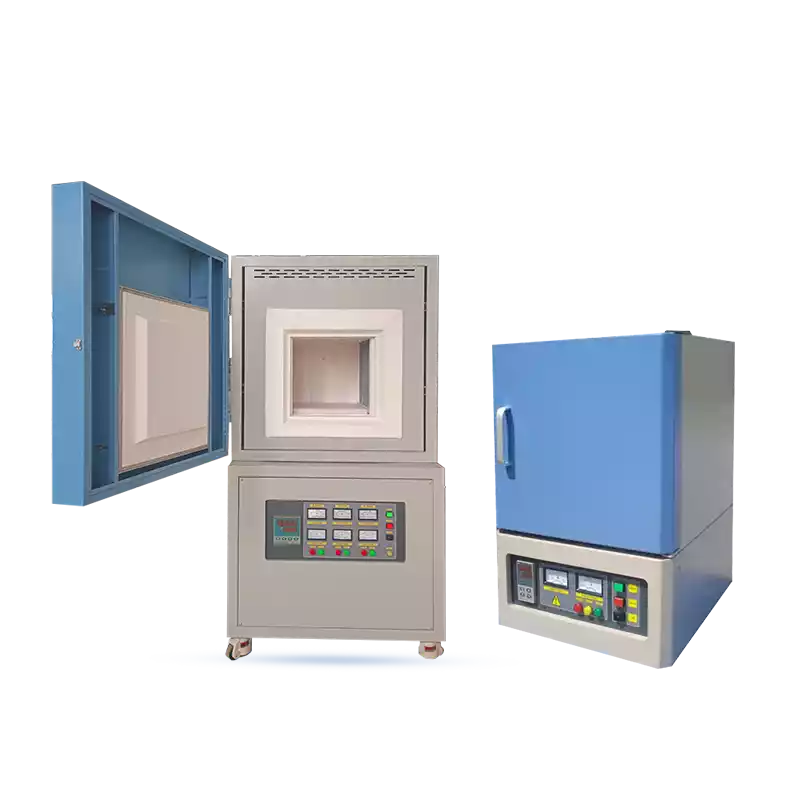

High Temperature Muffle Furnaces

High-temperature muffle furnaces, featuring high-quality MoSi2 heating elements capable of reaching 1800°C, are advanced equipment widely used in ceramics, rare metals, electronic materials, glass, and laboratory research for sintering, annealing, calcination, and other processes.

CVSIC high-temperature box furnace series covers 1700°C and 1800°C ranges, with capacities from 1L to 100L and power up to 150kW, supporting applications from small laboratories to medium and large-scale industrial settings.

As a high-temperature muffle furnace manufacturer, we provide one-stop solutions — from standard models to customized designs —covering design, production, testing, installation, and technical support.

1700°C and 1800°C High-Temperature Muffle Furnace Manufacturer & Supplier

CVSIC As a high-temperature muffle furnace manufacturer, CVSIC provide one-stop solutions — from standard models to customized designs —covering design, production, testing, installation, and technical support.

CVSIC High Temperature Muffle Furnaces Features

- High-Temperature Capability: Up to 1800°C, meeting demands for high-temperature sintering, annealing, and heat treatment.

- Flexible Specifications: Capacity range of 1–100L, supporting small laboratory and medium-scale production line applications.

- Long-Life Heating Elements: MoSi₂ heating elements ensure stable long-term operation at high temperatures.

- Precision Temperature Control System: PID programmable temperature controller with multi-step programming, achieving temperature accuracy of ±1°C.

- Efficient Insulation Structure: High-performance ceramic fiber and alumina insulation layers reduce heat loss.

- Durable Structural Design: Double-layer steel casing with a forced-air cooling system ensures long-term reliability.

- Safety Protection: Equipped with over-temperature protection, power-off protection, and an automatic alarm system.

- Flexible Installation Options: Desktop or floor-standing installation to meet diverse spatial requirements.

Buy High-Quality High Temperature Muffle Furnace from China

Quick Navigation

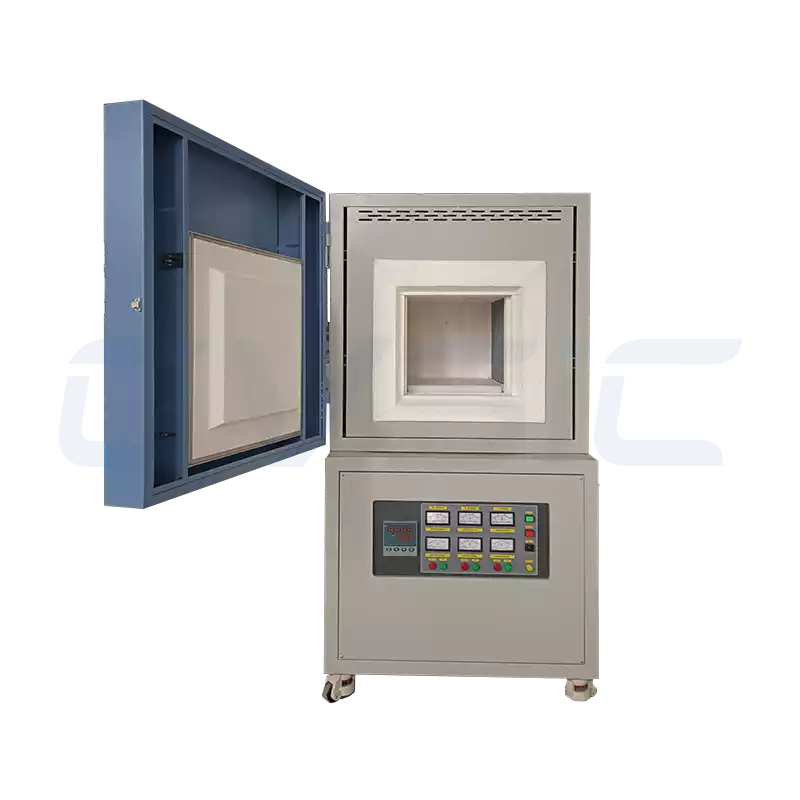

1800°C Industrial Muffle Furnace

- Name: CVSIC 1800°C Industrial Muffle Furnace

- Temperature: Maximum of 1800°C and operating temperature of 1700°C

- Heater: MoSi2 Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

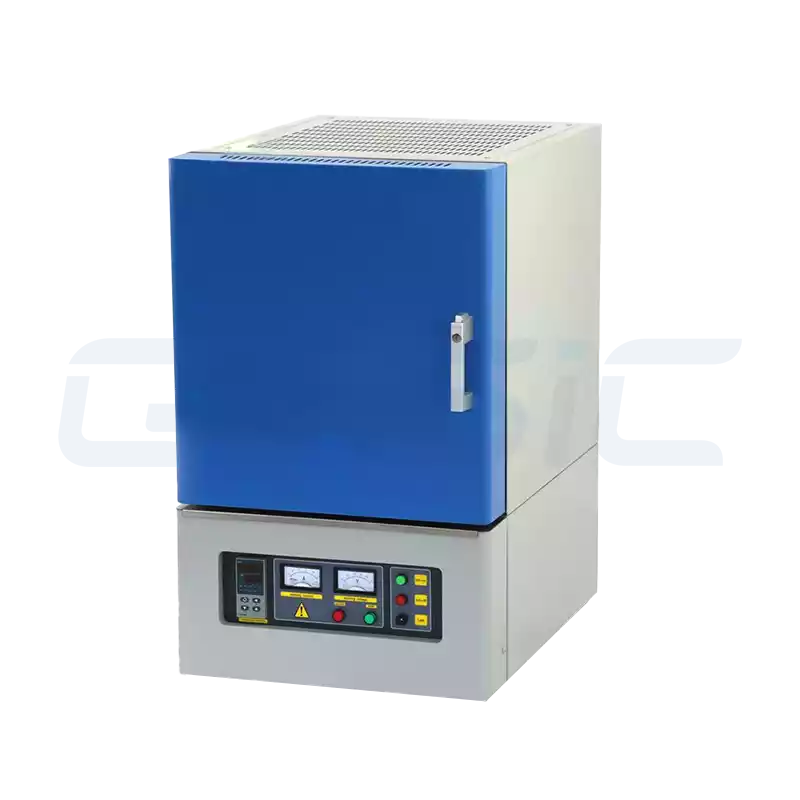

1800°C Small Muffle Furnace

- Name: CVSIC 1800°C Small Muffle Furnace

- Temperature: Maximum temperature of 1800°C, with stable operation at 1700°C

- Heater: U-shaped MoSi2 heating element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Large Muffle Furnace

- Name: CVSIC 1700°C Large Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Medium Muffle Furnace

- Name: CVSIC 1700°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Small Muffle Furnace

- Name: CVSIC 1700°C Small Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

Custom High-Temperature Box Furnace From China

We offer not only standardized high-temperature muffle furnace models but also tailored solutions for specific process needs:

- Customized Furnace Chamber: Adjustable capacity, dimensions, power, and temperature control systems

- Control System Upgrades: Support for multi-step curve programming and data logging

- OEM/ODM Services: Provide white-label production and brand customization

- Technical Support: Offer guidance on model selection and installation services

- After-Sales Support: Provide operation training, maintenance support, and spare parts supply

Why Choose CVSIC?

Solve your problems with cvsic’s powerful capabilities

Production Capacity

Quality Control

Quick Support

Global Partnership

CVSIC High-Temperature Muffle Furnace Application Areas

CVSIC high-temperature muffle furnaces are widely used in various industrial and scientific scenarios, addressing the full range of needs from experimental validation to production processing.

Ceramics and Advanced Materials

- Sintering of structural and functional ceramics

- Preparation of high-temperature materials like zirconia and alumina

- Heat treatment of ceramic powders and coating materials

Metallurgy and Rare Metals

- Heat treatment of alloys and powder metallurgy materials

- Sintering and annealing of rare metals

Electronics and Semiconductors

- Sintering and oxidation of ceramic substrates

- High-temperature aging tests for electronic components

Scientific Research and Laboratories

- Development and performance testing of new materials

- High-temperature chemical reactions and thermal decomposition experiments

Glass and Special Materials

- High-temperature softening and sealing tests

- Research and validation of special refractory materials

FAQ

What processes are high-temperature muffle furnaces suitable for?

Suitable for high-temperature sintering, annealing, and heat treatment in ceramics, metals, electronic materials, glass, and scientific research.

What’s the difference between 1700°C and 1800°C muffle furnaces?

The 1800°C model can operate at higher temperatures for extended periods, making it suitable for materials that require higher temperatures; the 1700°C model is ideal for standard high-temperature sintering and heat treatment.

Do they support vacuum or controlled atmosphere functions?

This series is designed for standard air environments and does not support vacuum or controlled-atmosphere systems; it is suitable for sintering and heat treatment in air.

What is the delivery time?

Standard models ship in 7–15 days, customized models in about 30 days, depending on order size and specifications.

Is after-sales support provided?

We offer remote technical support, operation training, and long-term spare parts supply to ensure stable equipment operation.

Whether for research laboratories or industrial production lines, CVSIC high-temperature muffle furnaces deliver stable, efficient, and reliable performance to meet your high-temperature process needs.

From 1L compact laboratory furnaces to 100L industrial equipment, we provide flexible options and customized solutions.

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support