In dental clinics and laboratories, dental furnaces are essential pieces of equipment. Whether producing realistic all-ceramic crowns or sintering durable zirconia restorations, dental furnaces play a vital role in the process. As an engineer at CVSIC, I recognize that a top-quality dental furnace can transform your laboratory’s productivity. Today, we will explore the definition, various types, selection criteria, and maintenance practices for dental furnaces to assist you in providing excellent care for your patients’ smiles.

What is a dental furnace? What does it do?

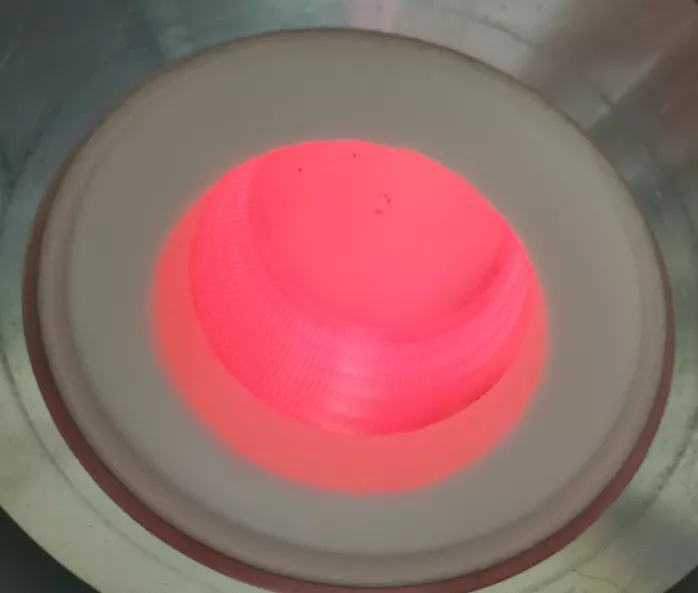

A dental furnace is a specialized high-temperature device intended for the processing of dental materials. Its main functions include sintering, firing porcelain, or thermally treating restorative substances such as zirconia, ceramics, and metals. By employing precise temperature management and programmable heating, these furnaces modify the physical and visual characteristics of materials, making them appropriate for dental use. In essence, a dental furnace serves as the “workbench” of a dental lab, converting raw materials into robust, aesthetically pleasing dental restorations.

CVSIC dental furnaces are renowned for their precise temperature control and durability. Whether for small dental practices or large laboratories, we offer customized solutions tailored to your needs.

Sintering Furnaces vs. Glazing Furnaces: What are the Key Differences?

Within the realm of dental furnaces, sintering furnaces and glazing furnaces are the two most prevalent types. Although their functions may overlap, they have distinct purposes and designs. Here are the main differences:

Dental Sintering Furnace

- Purpose: Mainly used for sintering high-strength materials such as zirconia, resulting in all-ceramic crowns, bridges, and other restorations.

- Operating Temperature: Generally falls between 1400°C and 1600°C, suitable for high-temperature sintering.

- Features: restorations’ sophisticated temperature control systems that guarantee a consistent zirconia crystal structure, enhancing the strength and translucency of restorations.

- Applications: Intended for dental laboratories that require high-precision, high-strength restorations.

- CVSIC Recommendation: Our zirconia sintering furnace employs intelligent temperature control technology to ensure stable sintering processes with yield rates of up to 99%.

Dental Porcelain Furnace

- Purpose: Utilized for firing ceramic materials, applying aesthetic coatings, or producing all-ceramic veneers, prioritizing restorative appearance.

- Operating Temperature: Typically ranges from 800°C to 1200°C, ideal for low-temperature ceramic processing.

- Features: Focuses on multi-stage programmed heating and vacuum conditions to secure perfect bonding between ceramic layers and substrates.

- Applications: Best suited for restorations that require meticulous aesthetics, such as anterior veneers or all-ceramic crowns.

- CVSIC Recommendation: Our Dental porcelain Furnace allows for up to 100 custom programs to satisfy diverse and complex processing needs.

Common Dental Materials and Compatible Furnace Types

Different dental materials require specific processing temperatures and techniques, making the selection of a suitable furnace critical. Below are common dental materials and their compatible furnace types:

Zirconia

- Characteristics: High strength, high translucency, commonly used for all-ceramic crowns, bridges, CVSIC’s, and implant restorations.

- Compatible Furnace: Sintering furnace (1400°C-1600°C).

- Precautions: The sintering process requires slow heating and cooling to prevent material cracking. CVSIC’s sintering furnace features built-in intelligent temperature control curves, ideally suited for zirconia processing.

Porcelain

- Features: Exceptional aesthetics, ideal for veneers or anterior restorations.

- Compatible Furnace Type: Porcelain furnace (800°C-1200°C).

- Precautions: Vacuum processing is required to minimize bubbles and ensure flawless aesthetics. CVSIC porcelain furnaces utilize vacuum pump technology to guarantee zero imperfections in finished products.

Metal Alloys

- Features: Used for metal-ceramic crowns or partial restorations, offering high strength but slightly reduced aesthetics.

- Compatible Furnace Types: Partial porcelain furnaces or specialized metal sintering furnaces (depending on alloy type).

- Precautions: Metal processing demands high temperature uniformity to prevent deformation caused by thermal stress.

Want to explore material-furnace compatibility in depth? Check out our Dental Material Processing Guide!

Key Factors for Selecting Dental Furnaces

Selecting the appropriate dental furnace for your lab or clinic necessitates thorough consideration. Here are essential factors to aid your choice:

Processing Requirements

- Determine your primary materials (zirconia, ceramics, or metals).

- Evaluate your production volume: Compact furnaces are suitable for small clinics, whereas large labs benefit from high-throughput devices.

Temperature Range & Control Precision

- Sintering furnaces need temperatures exceeding 1500°C, while porcelain furnaces require precise control near 1000°C.

- Choose CVSIC’s with advanced temperature control systems to avoid quality issues caused by fluctuations.

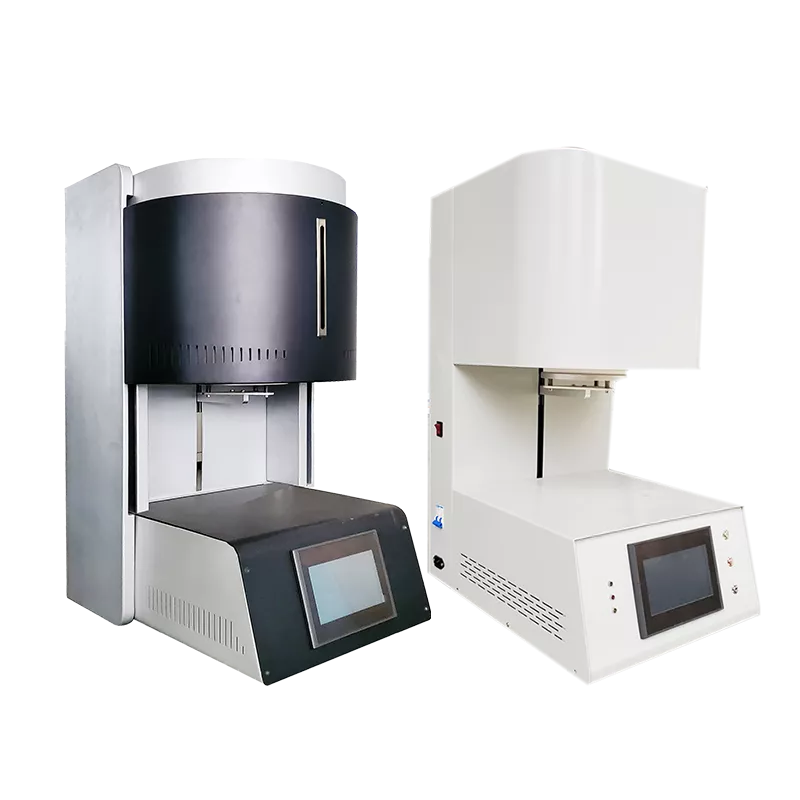

Equipment Size and Space

- Small clinics may select desktop dental furnaces to maximize space.

- Bigger laboratories should look into CVSIC’s high-throughput multi-functional furnaces, which support a range of processes.

Ease of Use and Programming

- Contemporary dental furnaces should allow multi-step program settings for various materials and fabrication methods.

- CVSIC dental furnaces come with touchscreen interfaces for easy operation, enabling quick learning for even newcomers.

After-Sales Support

Opt for brands that offer dependable after-sales assistance. CVSIC provides round-the-clock technical support and regular maintenance to keep your equipment running smoothly at all times.

Still unsure? View our guide on How to Choose a Dental Furnace for more purchasing advice!

Essential Knowledge for Using and Maintaining Dental Furnaces

To ensure long-term efficiency, a high-quality dental furnace requires correct usage and regular upkeep. Below are some practical suggestions:

Usage Suggestions

- Preheat and Calibrate: Make sure the furnace is clean and perform a temperature calibration before each use.

- Program Settings: Choose the correct heating curve according to the type of material to prevent damage from quick temperature fluctuations.

- Safe Operation: Confirm that the furnace door is securely fastened to avoid the escape of high temperatures. Use protective gloves while operating.

Maintenance Suggestions

- Regular Cleaning: Eliminate any residue from the furnace chamber to avoid contaminating fresh materials.

- Heating Element Inspection: Frequently examine the heating rods or coils for wear and replace them promptly to maintain temperature consistency.

- Software Updates: CVSIC dental furnaces allow for OTA firmware updates; regularly check for the most recent features.

Looking for more maintenance advice? Explore our Dental Furnace Maintenance Guide!

Why Choose CVSIC?

At CVSIC, we recognize that dental labs continually strive for efficiency and quality. Our dental furnaces are equipped with industry-leading temperature control technology, offering customized solutions to meet a range of needs, from small clinics to large laboratories.

Choose CVSIC for:

- High-Performance Equipment: Enjoy precise temperature control and up to 99% yield rates.

- Dedicated Service: Benefit from our global after-sales network and 24/7 technical support.

- Continuous Innovation: We release new furnace models annually to stay in line with dental industry trends. Contact CVSIC today to explore our dental furnace product line and find the ideal solution for your laboratory!

Conclusion

Dental furnaces are essential for dental laboratories. Choosing the right furnace enhances efficiency and results in high-quality restorations for patients. CVSIC is dedicated to offering high-performance, user-friendly dental furnace solutions to improve your laboratory’s capabilities. If you’d like to learn more about sintering or porcelain furnaces, visit our dental furnace product page or get in touch with our technical team!

FAQ

Can sintering furnaces and porcelain furnaces be used interchangeably?

Some multi-functional dental furnaces support both sintering and porcelain processes, but specialized models deliver superior performance for specific materials.

What is the lifespan of a dental furnace?

With proper use and regular maintenance, high-quality dental furnaces (such as CVSIC products) can last 8-10 years or longer. Regular replacement of heating elements further extends lifespan.

How do I choose a dental furnace for a small clinic?

Small clinics should prioritize compact, easy-to-operate models that are compatible with standard materials, such as zirconia and ceramics.

How long does a dental furnace take to complete a sintering cycle?

Zirconia sintering typically requires 6-8 hours (including cooling), while porcelain-fused-to-metal (PFM) crowns usually complete within 1-2 hours. Exact times depend on the material and program settings.

Does CVSIC offer customized dental furnace solutions?

Absolutely! We provide bespoke furnace designs tailored to the laboratory’s thermal and product volume requirements. Contact us for more details!