From our earlier guides on FeCrAl fundamentals and the seven primary grades, you already understand:

- FeCrAl comes in multiple tailored variants

- Cr and Al levels define absolute performance limits

- Each grade has a deliberate engineering focus

This article delivers a clear, head-to-head FeCrAl grade comparison — pinpointing which models best match specific duties — so you can select with confidence.

Quick-Reference FeCrAl Grades Comparison Table

Important note on “recommended long-term use temperature”: This reflects safe, predictable continuous operation under proper wire diameter, controlled surface loading (W/cm²), and stable atmosphere — not catalog maximums, short-burst limits, or marketing figures.

| Engineering Grade | Recommended Long-Term Temperature | Oxidation Resistance | Formability / Processing Difficulty | Relative Cost | Typical Applications & Best-Fit Duties |

|---|---|---|---|---|---|

| Low-Alloy FeCrAl | ≤1150°C | ★★☆☆☆ | ★☆☆☆☆ (Easy) | Low | Medium-temperature processes, cost-driven equipment |

| Standard / Workhorse FeCrAl | 1200–1250°C | ★★★☆☆ | ★★☆☆☆ | Medium | General-purpose industrial furnaces, muffle/box furnaces |

| Medium-High Al FeCrAl | 1250–1300°C | ★★★★☆ | ★★★☆☆ | Medium-High | Continuous high-temp duty in air/oxidizing atmospheres |

| High-Cr Stabilized FeCrAl | 1250–1300°C | ★★★★☆ | ★★★☆☆ | High | Extended-cycle operation, priority on reliability |

| High-Al Max-Temperature FeCrAl | 1300–1350°C | ★★★★★ | ★★★★☆ (Challenging) | High | Extreme-temperature designs with minimal cycling |

| Micro-Alloyed (Nb/Mo strengthened) | 1250–1350°C | ★★★★★ | ★★★★☆ | Higher | Demanding long-life, high-stability industrial applications |

| Custom-Optimized FeCrAl | Application-specific | Application-specific | Varies | Variable | Tailored solutions for unique or critical process conditions |

Correctly Interpreting the Comparison Dimensions

Most mis-selections stem not from insufficient data, but from misinterpreting what each column truly means in practice.

Recommended Long-Term Temperature

Engineering reality: The realistic continuous operating band where life is predictable, and failures are minimized — assuming good design practice (wire size, surface load, atmosphere control).

Key reminders

- Far below the melting point

- Not short-duration overload capability

- Definitely not advertised peak values

- The single most misunderstood parameter

Frequent cycling/start-stop? Treat listed temperatures as ~50–100°C, optimistic and derate accordingly.

Oxidation Resistance Rating

Measures the real driver of longevity:

- Speed and quality of Al₂O₃ scale formation

- Scale density and adherence

- Self-healing/regeneration at temperature

Interpretation:

- ★★☆☆☆ — Functional but highly condition-sensitive

- ★★★☆☆ — Broad, forgiving mainstream choice

- ★★★★☆ — Strong confidence in sustained high-temp exposure

- ★★★★★ — Oxidation is rarely the weak link

Processing / Formability Difficulty

Driven purely by alloy physics (especially Al content): higher Al → more demanding, more brittle → tighter tolerances needed for coiling, bending, and installation.

Real-world impact:

- Greater difficulty reduces the design/assembly margin

- High-Al grades suit experienced, high-precision production lines

- Avoid for quick retrofits or low-skill fabrication

Cost Considerations:

True lifecycle cost includes:

- Raw material price

- Scrap and forming losses

- Installation labor/time

- Expected service life

- Risk/cost of unplanned downtime

Field lesson: A wrong grade’s downtime expense usually dwarfs any upfront material savings.

Applicable Operating Conditions

Quick decision heuristics that matter most:

- Continuous duty >> frequent on/off → favor higher-Al grades

- New/untested equipment → stick to forgiving mid-range grades

- Pushing near 1300°C → select with margin, not “bare minimum.”

- Operating condition fit is the ultimate selector

Fast-Track Selection Pathway for Engineers

Narrow it down quickly:

- Design target ≤1200°C → 1cr20al3 Wire

- 1200–1300°C with continuous duty → 0Cr21Al6 Resistance Wire or 0Cr25Al5 Resistance Wire

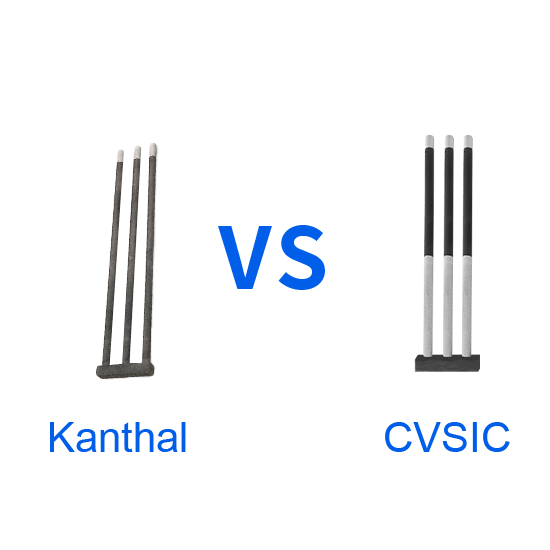

- ≥1300°C, minimal cycling, proven design → 0Cr21Al6Nb Resistance Wire Kanthal A1 Alternative or 0Cr27Al7Mo2 Wire Kanthal APM Alternative

- Unusual constraints or ultra-long life targets → Custom FeCrAl

Custom FeCrAl Alloy Manufacturer

CVSIC’s Field-Proven Selection Philosophy

Across real projects, we consistently favor:

- Building in a safety margin for extended life

- Choosing a slightly higher grade for added stability

- Steering clear of FeCrAl in unsuitable duties (e.g., aggressive cycling, reducing atmospheres)

Core insight: FeCrAl failures almost always come from pushing it right to — or beyond — its practical envelope, not from inherent weakness.

FAQ About FeCrAl Selection

Can I pick the “highest-grade” FeCrAl from the table?

Not advisable in practice. Top-tier grades offer peak performance but come with narrower operating windows and lower tolerance for deviations — often leading to earlier failure if conditions aren’t perfect.

Two grades show similar long-term temperatures — which wins?

Prioritize the one with:

- Easier processing / better formability

- Broader field track record

- Larger built-in safety margin

Budget is tight — how do I stay safe?

Protect yourself by:

- Accepting a modestly lower design temperature

- Using a thicker wire diameter

- Strictly controlling surface loading

…rather than compromising on grade. The small material savings rarely justify the risk.