Product catalogs often list a dozen FeCrAl grades: 0Cr23Al5, 0Cr25Al5, 0Cr21Al6, 0Cr27Al7Mo2, 0Cr21Al6Nb, and more.

The real questions are:

- Why so many variants?

- What specific engineering problems do adjustments in Cr and Al content solve?

- Is this random tweaking, or a deliberate progression?

Memorizing “which one handles the highest temperature” is not enough. In actual industrial service, that shortcut usually leads to costly field failures and re-learning the hard way.

Why FeCrAl Can’t Be a One-Formula Solution?

One core truth: No single composition can optimally serve every high-temperature heating duty.

FeCrAl alloy design is a deliberate series of trade-offs:

- Higher temperature capability → requires more Al

- Better mechanical strength and formability → limits how high Al can go

- Stronger overall oxidation resistance → demands synergy between Cr and Al

- Longer predictable service life → depends on grain structure, oxide adhesion, and more

Each grade is therefore purpose-tuned by varying Cr and Al levels to prioritize different performance priorities.

The Two Core Axes of FeCrAl Grade Evolution

Axis 1: Aluminum (Al) Content — Controls maximum temperature and oxide film quality

Al is the cornerstone element that enables the formation of a protective, self-healing Al₂O₃ (alumina) scale.

| Al Content (wt.%) | Typical Engineering Behavior |

|---|---|

| 3–4% | Slow oxide formation, limited max. temperature |

| 5–6% | Stable, dense oxide film; best all-around performance |

| ≥7% | Highest temperature capability, but increased brittleness and forming challenges |

Engineering principle: More Al is not always better. The goal is reliable, dense oxide formation under your specific operating envelope.

Axis 2: Chromium (Cr) Content — Governs early oxidation behavior and long-term structural integrity

Cr plays a supporting but critical role:

- Accelerates initial Al₂O₃ scale development

- Enhances early-stage oxidation resistance

- Improves matrix stability during prolonged high-temperature exposure

| Cr Content (wt.%) | Engineering Impact |

|---|---|

| <20% | Unstable early oxidation, higher life variability |

| 20–23% | Well-balanced performance and broad applicability |

| ≥25% | Superior high-temperature structural stability (at higher cost/complexity) |

Engineering Breakdown of the Seven Key FeCrAl Grades

These categories reflect CVSIC’s practical field-based performance layering — not rigid “official” classes.

Low-Alloy Grade — e.g., 1Cr20Al3 / similar (~20% Cr, 3–4% Al)

- Max continuous temperature: ~1100–1200°C

- Positioning: Cost-sensitive medium-temperature applications with modest thermal margin

- Summary: Serviceable, but avoid pushing close to limits for extended periods

Standard / Workhorse Grade — 0Cr23Al5 (~22–23% Cr, ~5% Al)

- Max continuous temperature: ~1250–1300°C

- Positioning: The global mainstream choice for industrial electric furnaces

- Key strength: Excellent balance of temperature capability, service life, and cost

High-Al Oxidation-Focused Grade — 0Cr21Al6 (~21% Cr, ~6% Al)

- Fast-forming, highly stable alumina scale

- Advantages: Superior performance in continuous high-temperature oxidizing atmospheres

- Trade-off: Reduced cold ductility → requires careful forming and winding processes

High-Cr Stabilized Grade — 0Cr25Al5 (~25%+ Cr, 5–6% Al)

- Enhanced matrix stability and balanced oxidation/strength

- Best suited for applications prioritizing long-term reliability over lowest cost

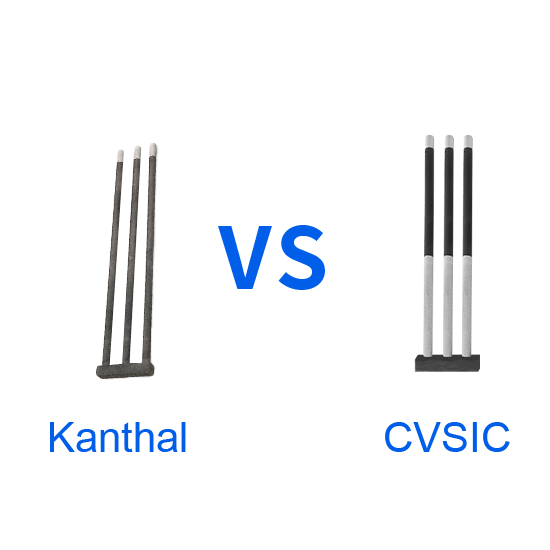

Micro-Alloyed / Dispersion-Strengthened Grades — e.g., 0Cr21Al6Nb (Nb addition, Kanthal A-1 equivalent), 0Cr27Al7Mo2 (Mo addition, Kanthal APM equivalent)

- Trace additions (Nb, Mo, etc.) refine grain, boost creep resistance, and improve oxide adhesion

- Ideal for projects with strict life/stability targets under demanding conditions

Custom-Optimized FeCrAl Increasingly common in CVSIC projects: Tailored compositions that sacrifice peak temperature for better behavior in specific duties, such as:

- Reduced sensitivity to thermal cycling

- Optimized surface loading tolerance

- Maximized life at targeted wire diameters

For complete comparisons and more profound FeCrAl knowledge, see our comprehensive FeCrAl Alloy Guide.

The True Direction of Evolution

In one engineering sentence: FeCrAl grades evolve not to chase ever-higher catalog temperatures, but to deliver more predictable, controllable, and reliable high-temperature behavior.

Priorities have consistently been:

- Stronger, more adherent oxide film

- Longer, more predictable service life

- Reduced uncertainty in real-world service

Practical Selection Guidance

When choosing a FeCrAl grade:

- Skip the simplistic question: “What’s the max temperature?”

- Ask the decisive questions instead:

- What wire diameter are you using?

- What surface loading (W/cm²) is planned?

- How frequent are start-stop cycles?

- Is this a continuous, long-term duty, or is it cyclic?

The grade is only a starting point — the actual operating condition determines success.

Final Thought

The value of understanding FeCrAl grades lies not in picking the “highest-spec” or most expensive option, but in selecting the one that best matches — and survives — your specific process realities.

FAQ

Does higher Al always deliver longer life?

No. While higher Al levels boost oxidation resistance, excessive levels increase brittleness, create difficulties, and increase the risk of early cracking under non-ideal conditions.

Why don’t high-end projects always choose the “top-grade” FeCrAl?

Extreme grades have narrower operating windows and lower fault tolerance. Deviations from ideal conditions often cause faster failure than a more forgiving mid-range grade.

Can different FeCrAl grades be directly substituted?

Rarely advisable. Even when nominal maximum temperatures appear similar, differences in oxide behavior, creep, cycling response, and life expectancy can be substantial.