In real industrial electric heating setups, FeCrAl isn’t “the safe bet”—it’s actually one of the most misunderstood and misused materials we run into.

We keep seeing the same disasters on job sites:

- Spec calls for 1200℃, so they pick FeCrAl

- Numbers all look good on paper

- 3–6 months later: wires snap early, heavy oxidation, power drifting all over the place

The root cause is rarely poor material quality. It is almost always incomplete understanding of FeCrAl’s true operating boundaries.

This guide clearly defines what FeCrAl can — and cannot — reliably do.

What exactly is FeCrAl?

FeCrAl (iron-chromium-aluminum) is a high-temp resistance heating alloy family built around an iron base.

- Fe → the main structure

- Cr → helps fight oxidation

- Al → creates the star of the show: the protective layer

The magic isn’t in the exact mix percentages—it’s in how stable and continuous that aluminum-based oxide stays.

How FeCrAl Works?

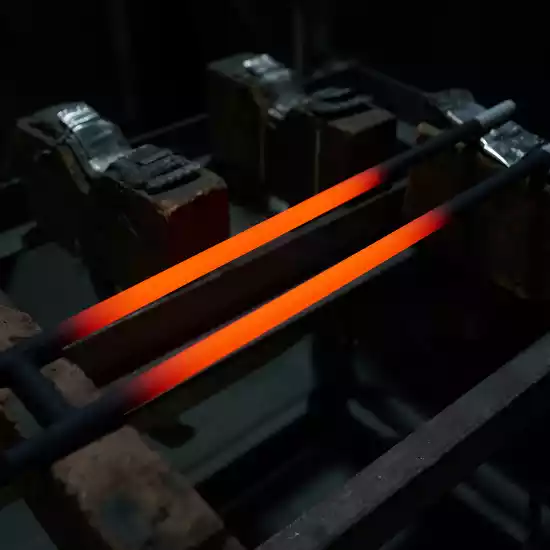

When you run current through FeCrAl at high heat, it grows a tight, tough Al₂O₃ (alumina) skin on the surface.

- That alumina layer is electrically insulating.

- Has a crazy high melting point

- Blocks oxygen diffusion like a fortress

This protective film is literally the only reason FeCrAl can hang at 1200–1400℃ for long periods.

Critical engineering reality

FeCrAl’s high-temperature capability depends far more on the integrity and renewal of this alumina film than on the intrinsic strength of the alloy itself.

FeCrAl Alloy Grades

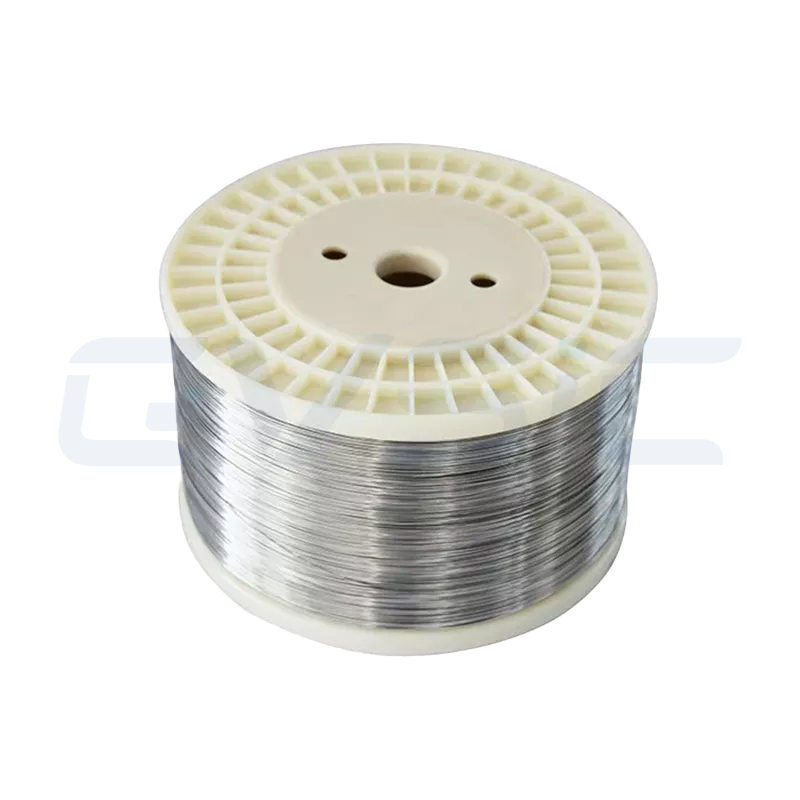

FeCrAl is available in seven main grades. CVSIC supplies the full range — refer to our FeCrAl grade comparison for detailed differences, or contact us directly for specifications on any specific grade.

Why Industrial Systems Choose FeCrAl

Real-World Engineering Advantages

| Engineering Requirement | FeCrAl Benefit |

|---|---|

| Continuous high-temperature duty | Permits higher surface temperatures |

| Oxidizing air atmosphere | Highly stable Al₂O₃ protective film |

| Cost sensitivity | Significantly lower cost than high-nickel NiCr alloys |

| High-power furnace designs | Supports higher power density |

Important caveat: FeCrAl is high-temperature capable, but not operationally forgiving.

Where FeCrAl actually belongs in industrial systems

Think of FeCrAl as a “push-the-temperature-boundary” material.

It shines in:

- Tube furnaces

- Box furnaces

- General industrial electric ovens

- Ceramic sintering

- Powder metallurgy sintering

- Lab-scale high-temp test rigs

But only when:

- Operating conditions stay steady

- You aren’t cycling it on and off all the time

- The atmosphere is known and controlled

FeCrAl Performance Boundaries

Rated temperature ≠ safe continuous operating temperature

A very common engineering misconception: “The spec says 1400°C, so running at 1250°C should be perfectly safe.”

Reality is more nuanced:

- Catalog maximum temperature

- ≠ realistic long-term operating temperature

- ≠ safe temperature at your specific wire diameter and power loading

Smaller wire diameters significantly reduce the practical temperature ceiling.

High Sensitivity to Thermal Cycling

Frequent on/off cycles cause:

- Repeated cracking of the alumina film

- Incomplete or defective regeneration

- Local exposure of the iron-rich base metal → rapid “breakaway” oxidation

This explains why FeCrAl is generally unsuitable for systems with aggressive or frequently fluctuating temperature control.

Atmosphere Compatibility – Selective Strengths

FeCrAl performs reliably in:

- Air

- Mildly oxidizing conditions

It struggles in:

- Sulfur-bearing atmospheres

- Strongly reducing environments

- High-carbon / carburizing conditions

Any of these can destabilize or destroy the protective Al₂O₃ layer.

Most Common Failure Modes

Excessive power density

- Surface loading (W/cm²) exceeds safe limits

- Localized overheating

- Erosion / burnout of the oxide film → wire failure

Undersized wire diameter

Chosen to achieve:

- Faster heat-up rate

- Lower material cost

Consequences:

- Excessively high surface temperature

- Reduced mechanical strength

- Accelerated thermal fatigue

Direct carry-over of NiCr design rules

FeCrAl is not NiCr. Copying NiCr-based layouts and assumptions is one of the leading causes of premature FeCrAl failure.

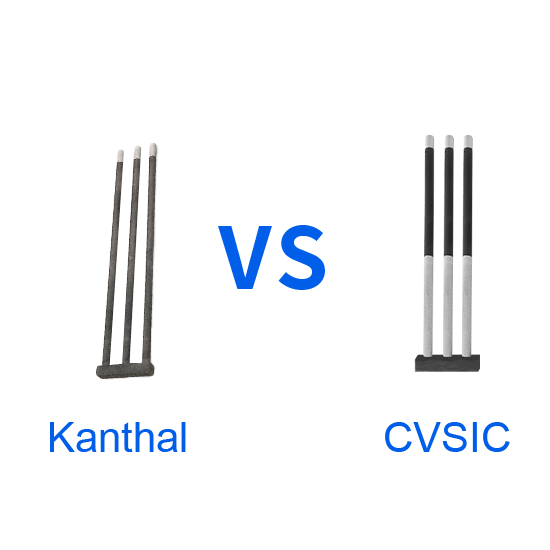

FeCrAl vs. NiCr – Head-to-Head Comparison

| Property | FeCrAl (Fe-Cr-Al) | NiCr (Ni-Cr) |

|---|---|---|

| Maximum service temperature | Higher | Lower |

| Primary oxide film | Al₂O₃ (alumina) | Cr₂O₃ |

| Thermal cycling tolerance | Lower | Higher |

| High-temperature strength | Lower | Higher |

| Material cost | Lower | Higher |

| Design margin / forgiveness | Low | High |

Bottom line:

FeCrAl wins on raw high-temperature performance.

NiCr wins on stability and forgiveness.

How CVSIC approaches FeCrAl projects

We never just ask “What temperature do you want?”

We always drill down on:

- Real surface watt loading

- Wire diameter and total length

- How often does it cycle on/off

- Exact atmosphere

- How the heating elements are mechanically supported

One wrong call on FeCrAl usually means the whole furnace is down.

FeCrAl isn’t a “just use it for high temp” material.

It’s an engineering material that demands respect for its real limits.

If you’re building or running industrial electric heat systems, understanding where the edges are matters way more than memorizing catalog numbers.

FAQ

It says 1400℃—why don’t we ever see people actually running it there?

Because 1400℃ is the absolute ceiling, not a practical long-term number. Wire size, watt density, and atmosphere usually drag the safe limit down significantly.

Can I just swap FeCrAl for NiCr?

You can—but you have to redesign everything.

Direct drop-in without changing parameters almost always ends badly

Short life means bad material, right?

Nope, not always.

Nine times out of ten, it’s a mismatch between how the system was designed and what FeCrAl can actually handle.

Thicker wire = always safer?

Yes—when power is the same.

Thicker wire drops surface loading and keeps the oxide layer happier and more stable.