FeCrAl Alloy Comparison and Selection Guide

From our earlier guides on FeCrAl fundamentals and the seven primary grades, you already understand: This article delivers a clear,…

From our earlier guides on FeCrAl fundamentals and the seven primary grades, you already understand: This article delivers a clear,…

Ethan

Product catalogs often list a dozen FeCrAl grades: 0Cr23Al5, 0Cr25Al5, 0Cr21Al6, 0Cr27Al7Mo2, 0Cr21Al6Nb, and more. The real questions are: Memorizing…

Ethan

In real industrial electric heating setups, FeCrAl isn’t “the safe bet”—it’s actually one of the most misunderstood and misused materials…

Ethan

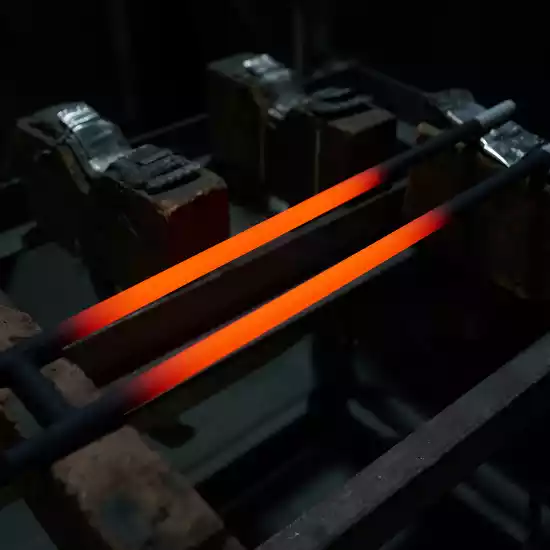

In high-temperature engineering, heating elements are the “heart” of furnace and kiln systems—their durability impacts uptime, energy efficiency, and operating…

Ethan

In the realm of high-temperature industrial heating, silicon carbide and molybdenum disilicide heating elements are the primary materials used. These…

Ethan

Imagine you’re running a ceramic factory where the kiln must operate continuously at 1700°C, and any failure of the heating…

Ethan

In high-temperature industrial settings, whether it’s kiln firing in ceramic factories, semiconductor crystal growth, or new energy battery production, selecting…

Ethan

Imagine you’re running a ceramic factory where the tunnel kiln must operate steadily at 1450°C, and any downtime could result…

Ethan

In high-temperature industrial settings, such as ceramic firing, metal heat treatment, or semiconductor production, Silicon Carbide Heating Elements are essential…

Ethan

In high-temperature industrial settings, whether it’s ceramic firing, metal heat treatment, or semiconductor crystal growth, Silicon Carbide Heating Elements play…

Ethan

Imagine a high-temperature industrial setting: a ceramic plant’s tunnel kiln operating 24/7, a semiconductor production line requiring precise temperature control…

Ethan