Routine maintenance and cleaning are vital for ensuring the longevity of your muffle furnace and the success of your experiments. Whether your furnace uses resistance wire, SiC, or MoSi2 heating elements, neglecting upkeep can result in unstable temperatures, component damage, or even failed trials.

In this guide, CVSIC outlines practical tips for daily maintenance and cleaning to keep your equipment in peak condition while minimizing operational costs.

Why Routine Maintenance and Cleaning Matter for Muffle Furnaces

Muffle furnaces operate under prolonged high-temperature and heavy-load conditions, exposing heating elements, furnace chambers, and control systems to oxidation, dust buildup, or aging. Without proper care, this can lead to:

- Performance degradation: Increased temperature deviations and reduced uniformity.

- Shortened component life: For instance, accelerated surface oxidation on SiC heating elements can cut lifespan by 20%-30%.

- Sample contamination: Dust or residues compromising experimental outcomes.

- Safety risks: Overheating or electrical issues heightening the chance of failures.

With a structured maintenance approach, you can extend furnace body life by 30%-50%, while preserving heating uniformity and operational safety.

Basic Cleaning After Daily Use

| Cleaning Area | Methods and Precautions |

| Furnace Chamber Walls | Use a soft-bristle brush or vacuum to remove dust and residues; avoid metal tools that could scratch surfaces. |

| Door Seals | Inspect seals regularly for integrity; replace immediately if aging or detachment is detected. |

| Bottom Trays | Clear any sample residues or slag promptly to prevent oxide buildup from disrupting the thermal field. |

| Exterior and Vents | Wipe with a dry or slightly damp cloth; ensure vents remain unobstructed to prevent dust accumulation. |

Note: Never clean while the furnace is hot—allow it to cool to below room temperature (<50°C) before proceeding.

6 Key Tips for Muffle Furnace Maintenance and Cleaning

1. Regular Chamber Cleaning to Prevent Contamination

- Clean the furnace chamber every 1-2 months to remove dust, sample residues, or oxides using a soft brush or specialized cleaner.

- Dust buildup can contaminate samples (e.g., impurities in ceramic sintering) or reduce thermal efficiency, raising energy use by up to 10%. Acidic residues may also corrode chamber materials like alumina fiber.

Operational Tips:

- Power off and cool to room temperature.

- Use the soft brush provided by CVSIC for chamber cleaning, steering clear of abrasive tools.

- For stubborn residues, apply a neutral cleaner, wipe thoroughly, and ensure complete drying before reuse.

2. Inspecting Heating Element Condition

Every 3-6 months, examine the appearance and resistance of resistance wire, SiC, or MoSi₂ elements.

- Resistance wire: Check for breaks or oxidation (white/green powdery deposits).

- SiC Heating Elements: Monitor surface oxide layers (>2 mm warrants attention) or cracks.

- MoSi2 Heating Elements: Verify end connections for looseness, oxidation, or crumbling.

Operational Tips:

- Measure and log resistance values after every 500 hours of operation to track trends.

- Use a multimeter for testing; consider replacement if resistance rises >20% for wire, >30% for SiC, or >10% for MoSi₂. How to determine muffle furnace heating elements need replacement?

Mosi2 heating elements for muffle furnaces

3. Calibrating Temperature Sensors and Control Systems

- Calibrate thermocouples and PID controllers every 6 months to maintain measurement accuracy.

- Aging or dust on thermocouples can cause ±5-10°C deviations, undermining experiment reproducibility.

- Misadjusted PID parameters reduce temperature control efficiency.

Operational Tips:

- For thermocouples: Regularly inspect plugs and protective sheaths to avoid oxide interference with accuracy.

- For PID controllers: Keep dry and away from high-humidity areas to prevent circuit drift.

- Temperature calibration: Recommended every 1000 hours of operation or every 6 months.

4. Checking Door Seals and Insulation Layers

- Monthly inspections: Look for aging, cracking in door seals, and damage to insulation (alumina fiber or ceramic boards).

- Poor sealing leads to heat loss and higher energy consumption.

- Damaged insulation impairs temperature uniformity, affecting sample quality.

Operational Tips:

- Repair or replace seals with high-temperature sealant as needed.

- Inspect insulation for cracks or shedding; address promptly to restore integrity.

- Always ensure the door is fully closed during operation to minimize air leaks.

5. Maintaining Chamber Dryness to Prevent Oxidation

- Keep the chamber dry before and after experiments; in humid conditions, preheat at 200°C for 30 minutes if necessary.

- Moisture accelerates oxidation in SiC and MoSi₂ (e.g., low-temperature oxidation producing powder on MoSi₂) and promotes rust on resistance wire, reducing lifespan by 20%.

- After use, ventilate to dry thoroughly; store in low-humidity environments (<50% RH) and consider adding desiccants.

SiC heating elements for muffle furnaces

6. Monitoring Energy Use and Operational Logs

- Log energy consumption, ramp-up times, and temperature data for each run to spot anomaly trends.

- A 15%-20% rise in energy use or extended ramp times may signal aging elements or dust—proactive maintenance prevents breakdowns.

- Monthly reviews of historical data: Investigate promptly if anomalies appear, such as a 10% energy increase.

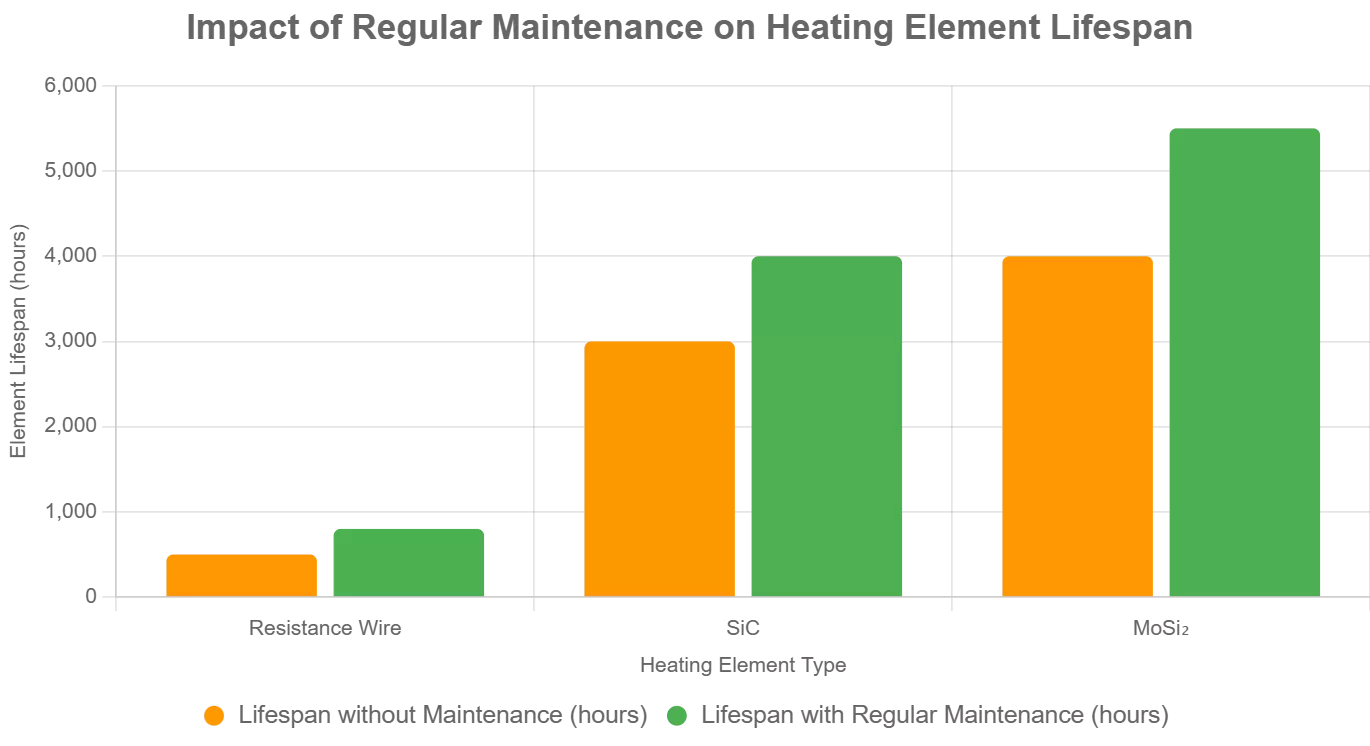

Impact of Maintenance on Muffle Elements Lifespan

The following highlights the lifespan extension effects of routine maintenance on heating elements (based on CVSIC data):

Maintenance Focus for Different Elements

- Resistance wire: Remove oxide powders, inspect for breaks, and limit operation to <1100°C.

- SiC: Protect from moisture, periodically remove surface oxides, and avoid acidic atmospheres.

- MoSi₂: Prevent low-temperature oxidation (400-600°C); cool rapidly to <300°C after high-heat runs.

Preventive Maintenance Schedule (Recommended Intervals)

| Maintenance Task | Interval | Details |

| Chamber Cleaning | Weekly | Remove dust and residues |

| Heating Element Inspection | Monthly | Check resistance variations |

| Temperature Control Calibration | Every 6 Months | Verify thermocouple and PID accuracy |

| Insulation Layer Check | Every 6 Months | Inspect for cracks or degradation |

| Electrical Connections | Annually | Tighten terminals to prevent loose contacts |

By incorporating regular chamber cleaning, element inspections, sensor calibrations, seal and insulation upkeep, dryness maintenance, and energy monitoring, you can substantially extend your muffle furnace’s service life and enhance experimental precision.