Imagine a high-temperature industrial setting: a ceramic plant’s tunnel kiln operating 24/7, a semiconductor production line requiring precise temperature control for crystal growth, or an electric vehicle battery production line striving for greater efficiency.

Behind these scenes, a critical component stands out—Silicon Carbide Rods (SiC Rods).

As high-performance non-metallic heating elements, silicon carbide rods, with their high-temperature resistance, corrosion resistance, and excellent thermal conductivity, are core components in numerous industries.

CVSIC Silicon Carbide Heating Elements, with their high purity and customized designs, deliver more efficient and reliable solutions for industrial users in China and worldwide.

This article explores the diverse applications and unique advantages of silicon carbide rods, introducing how CVSIC provides tailored heating solutions to meet your industrial needs. Whether you’re a ceramic manufacturer, a semiconductor engineer, or a new energy pioneer, you’ll find the information you need here.

What Are Silicon Carbide Rods?

Silicon carbide rods are heating elements made from high-purity silicon carbide material, sintered at temperatures reaching 2200°C. Their core advantages include:

- High Thermal Conductivity: Rapid heat transfer ensures uniform heating.

- High-Temperature Resistance: Stable operation in environments up to 1600°C.

- Corrosion Resistance: Outstanding performance in harsh acidic or alkaline environments.

- Wear Resistance: High hardness (Mohs 9.5) ensures long-term durability.

CVSIC Silicon Carbide Heating Elements further enhance purity and performance through optimized production processes. Whether in standard rod, U-shaped, or complex custom shapes, CVSIC meets specific industrial demands, providing heating technology support for global high-temperature manufacturing.

Main Applications of SiC Heating Elements

Silicon carbide rods demonstrate their versatility across multiple fields. Below are their primary application scenarios:

Industrial Heating Applications

- Electric Furnace Heating: In ceramics, glass, and metallurgy industries, silicon carbide rods are widely used as heating elements in tunnel kilns, roller kilns, and vacuum furnaces. For example, ceramic plants depend on SiC heating elements for high-temperature firing to ensure product quality.

- Heat Treatment Processes: In the automotive and aerospace industries, silicon carbide rods are utilized in tempering, annealing, and brazing processes, thereby ensuring the high strength and durability of metal components.

- Chemical Processing: Due to their corrosion resistance, SiC rods are used in the chemical industry to heat acidic or alkaline solutions, particularly in harsh environments.

CVSIC silicon carbide heating elements provide highly durable heating solutions for global ceramic and metallurgical enterprises, reducing equipment maintenance frequency and saving costs.

Semiconductor and Electronics Manufacturing

- Semiconductor Production: Silicon carbide rods provide stable high-temperature environments for crystal growth, epitaxy (thin-layer growth), and doping processes, ensuring precision in chip manufacturing.

- Electronic Component Processing: In wafer processing, the high thermal stability of SiC rods enables complex processes such as silicon wafer heat treatment.

- CVSIC Advantage: CVSIC’s silicon carbide rods, with precise temperature control, meet the semiconductor industry’s demands for high purity and consistency, supporting the global chip industry’s development.

Applications in New Energy

- Electric Vehicles (EV): Silicon carbide rods are used in high-temperature sintering for EV power systems (e.g., traction inverters), improving battery and motor efficiency.

- Photovoltaics and Fuel Cells: SiC rods support sintering and roasting processes in solar panel and fuel cell production, advancing the development of green energy.

- Quantum Technology: In high-precision, high-temperature environments, silicon carbide rods are being used in the development of quantum computing devices.

- CVSIC Innovation: CVSIC silicon carbide heating elements are optimized for new energy applications, offering enhanced energy efficiency and supporting China’s goals for carbon neutrality and peak carbon reduction.

Other Applications

- Kiln Furniture: In high-end ceramic and glass production, silicon carbide rods are used as kiln furniture support structures, ensuring high-temperature stability.

- Positioning Pins and Dilatometers: In welding and material testing, the wear resistance of SiC rods ensures high precision and accuracy.

- Fishing Gear: Due to their wear resistance, silicon carbide rods are used in high-end fishing rod guides, extending service life.

Advantages of Silicon Carbide Rods

Why choose silicon carbide heater? Here are their core advantages:

- Exceptional Durability: Hardness reaching 16 GPa, greatly exceeding traditional materials, reducing replacement frequency.

- Superior Thermal Performance: Minimal deformation at high temperatures with strong thermal shock stability.

- Energy Efficiency: High thermal conductivity reduces energy loss, particularly in EV and photovoltaic industries.

- Flexibility: Available in rod, strip, or U-shaped forms, adaptable to various furnace designs.

- CVSIC’s Unique Advantage: CVSIC silicon carbide heating elements utilize high-purity materials and localized production processes, ensuring a lower impurity content and extended service life.

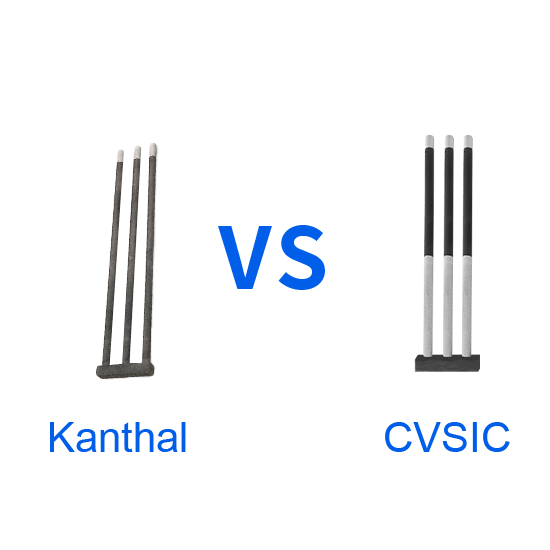

Comparison with Other Materials

Silicon carbide rods outperform other materials, as shown below:

- Silicon Carbide vs. Tungsten Carbide:

- SiC’s hardness (9.5 on the Mohs scale, compared to 8.5-9 for tungsten carbide) is better suited for high-temperature environments.

- Lower density (3.21 g/cm³ vs. 15.6 g/cm³) reduces equipment load.

- Silicon Carbide vs. Traditional Ceramics: SiC offers higher thermal conductivity and corrosion resistance, ideal for extreme environments.

- CVSIC’s Differentiation: CVSIC silicon carbide rods outperform market competitors in high-purity applications, particularly in the semiconductor and new energy industries.

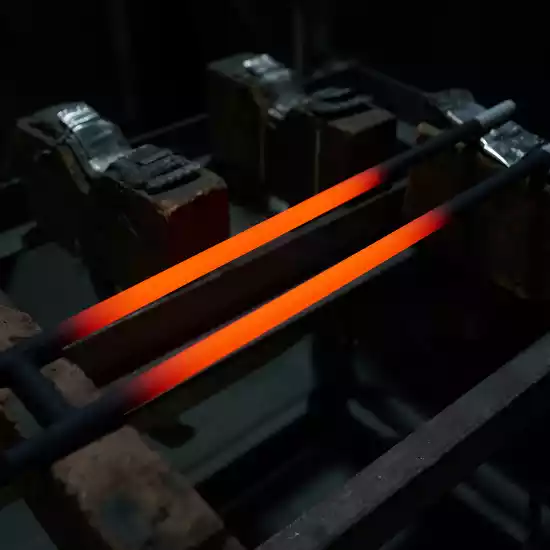

Case Study: Real-World Application of CVSIC Silicon Carbide Rods

A ceramic plant in Foshan faced frequent maintenance of tunnel kilns and high energy consumption. After adopting CVSIC Silicon Carbide Heating Elements:

- Results: Equipment downtime was reduced by 20%, thanks to the high durability and thermal stability of SiC rods.

- Data: At 1500°C, CVSIC rods maintained stable performance, resulting in a 15% reduction in energy consumption.

- Customer Feedback: “CVSIC’s custom design boosted our kiln efficiency and made cost management simpler.” This is the localized support for Chinese manufacturing needs.

Market Trends and Future Outlook

- Growth Drivers: Rapidly increasing demand for EVs, photovoltaics, and advanced ceramics is propelling the silicon carbide rod market.

- Market Size: The global silicon carbide market is expected to reach $9.5 billion by 2032, with a CAGR of 17.8%.

- Technological Innovation: Advances in silicon carbide coating technology and energy-saving designs further enhance the performance of SiC rods.

- CVSIC’s Role: As a Chinese brand, CVSIC is committed to developing sustainable heating solutions supporting the green industrial transition.

Conclusion

Silicon carbide rods are not only the cornerstone of high-temperature industrial applications but also indispensable innovative materials in new energy and semiconductor industries. CVSIC Silicon Carbide Heating Elements, with their high purity, customised designs, and localised support, offer reliable solutions for global high-temperature enterprises. From ceramic plant kilns to EV production lines, CVSIC is igniting the future of the industry.

Explore CVSIC’s silicon carbide heating elements and contact us for customized solutions to enhance your production efficiency and sustainability.

Reference:

- Saint-Gobain Performance Ceramics & Refractories

- Kintek Solution

- Global Market Insights

- The Business Research Company

- Meticulous Research