0Cr25Al5 Resistance Wire

0Cr25Al5 Alloy Heating Wire

0Cr25Al5 is a standard FeCrAl resistance alloy with high resistivity, killer oxidation resistance, and rock-solid performance up to 1300°C. It is super common in industrial furnaces, electric heating elements, and heat-treatment equipment. We do custom orders and B2B wholesale.

- Model: CV-0Cr25Al5

- Alloy Grade: 0Cr25Al5 (FeCrAl 255)

- Main Composition: Fe: Bal.; Cr: 24–26; Al: 4.8–6.0; Mo: ≤0.5

- Max Temp: 1300°C

- Resistivity (20°C): 1.42 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr25Al5 is a classic FeCrAl resistance alloy built for high-temp electric heating elements.

It is iron-based with around 25% chromium and 5% aluminum. In hot air, it forms a tough, stable Al₂O₃ oxide layer that protects it—perfect for ongoing high-heat applications in industrial resistance furnaces, heat-treatment setups, and ceramic kilns.

0Cr25Al5 Resistance Wire Characteristics

- Offers adequate oxidation resistance, but do not expect it to withstand high temperatures for extended periods; recommended long-term operating temperature should not exceed 950°C.

- Its aluminum content forms a thin aluminum oxide layer that provides some oxidation protection, but repeated thermal cycling can cause flaking.

- Low resistivity (approximately 1.10–1.20 μΩ·m), suitable for low-to-medium temperature heating applications such as household ovens and dryers.

- Key advantage: excellent workability. Easily bendable and windable without cracking, ideal for mass production.

0Cr25Al5 alloy resistance wire is recommended for high-temperature environments with limited budgets and moderate temperature requirements.

0Cr25Al5 Resistance Wire Composition and How It Works

Composition

- Iron (Fe) base

- Chromium (Cr): Boosts oxidation and corrosion resistance

- Aluminum (Al): Creates that Al₂O₃ protective layer at high temperatures

How It Works

Above 1000°C, the surface builds a tight aluminum oxide (Al₂O₃) film. This layer keeps oxygen from penetrating deeper, which slows the wire from thinning and its resistance from shifting.

Al₂O₃ layer → Awesome oxidation resistance → Steady resistance → Way longer lifespan

0Cr25Al5 (FeCrAl 255) Specs Table

| Item | Value |

|---|---|

| Model | CV-0Cr25Al5 |

| Alloy Grade | 0Cr25Al5 (FeCrAl 255) |

| Main Composition (%) | Fe: Bal.; Cr: 24–26; Al: 4.8–6.0; Mo: ≤0.5 |

| Max Continuous Temp | 1300°C |

| Resistivity (20°C) | 1.42 μΩ·m |

| Density | 7.1 g/cm³ |

| Thermal Conductivity | 12 KJ/m·h·°C |

| Expansion Coefficient | 14.7 ×10⁻⁶/°C |

| Melting Range | 1500–1530°C |

| Tensile Strength | ≥680 MPa |

| Elongation | ≥10% |

| Microstructure | Ferritic |

| Magnetic | Yes |

| Key Features | High Cr → Top-notch oxidation resistance; Stronger at high temps than 216/235 alloys |

| Common Uses | High-temp industrial electric furnaces, radiant tubes, heating elements, processing furnaces |

Power Load vs. Lifespan

How long 0Cr25Al5 lasts depends a lot on surface load.

| Surface Load (W/cm²) | Typical Temp | What Happens |

|---|---|---|

| ≤ 1.5 | ≤ 1100°C | Runs steady for the long haul |

| 1.5 – 2.5 | 1100–1250°C | Sweet spot for industrial use |

| ≥ 3.0 | ≥ 1300°C | Life drops off fast |

To keep things running smoothly long-term, stick to a surface load of under 2.5 W/cm².

Calculating Resistance for 0Cr25Al5 Wire

Formula

R = ρ × L ÷ A

What the variables mean:

- R: Resistance (Ω)

- ρ: Resistivity of 0Cr25Al5 (1.42 μΩ·m)

- L: Wire length (m)

- A: Cross-sectional area (mm²)

Example:

- Diameter: 1.0 mm

- Resistance: about 1.81 Ω per meter

This makes 0Cr25Al5 awesome for high-power, tight-space industrial heating setups.

Where You’ll Find 0Cr25Al5 Resistance Wire

It is all over in spots like:

- Industrial resistance furnaces

- Heat treatment and annealing furnaces

- Ceramic kilns and glass heating gear

- All sorts of electric heating elements and coils

In furnace systems, it delivers steady, high-temperature heat and reduces failures caused by oxidation.

How 0Cr25Al5 Stacks Up Against Other Materials

| Material | Max Temp | Resistivity | Typical Use |

|---|---|---|---|

| 0Cr21Al6 | 1250°C | Medium | Budget-friendly jobs |

| 0Cr25Al5 | 1300°C | High | Go-to for mainstream industrial furnaces |

| 0Cr27Al7Mo2 | 1350°C | Higher | Super extreme high-heat situations |

| NiCr | ≤ 1200°C | Lower | Medium-temp heating |

Quick tip: For high-temp applications in regular air, 0Cr25Al5 is usually a tougher, longer-lasting alternative to NiCr.

Failure Modes and Things to Watch Out For

- Sulfur in the air: It will wreck that protective Al₂O₃ layer and make it fail quicker

- Too much surface load: Leads to grain growth and brittleness from heat

- Lots of hot-cold cycles: Builds up mechanical fatigue

Keep the environment and power in check—that is the key to getting the most life out of it.

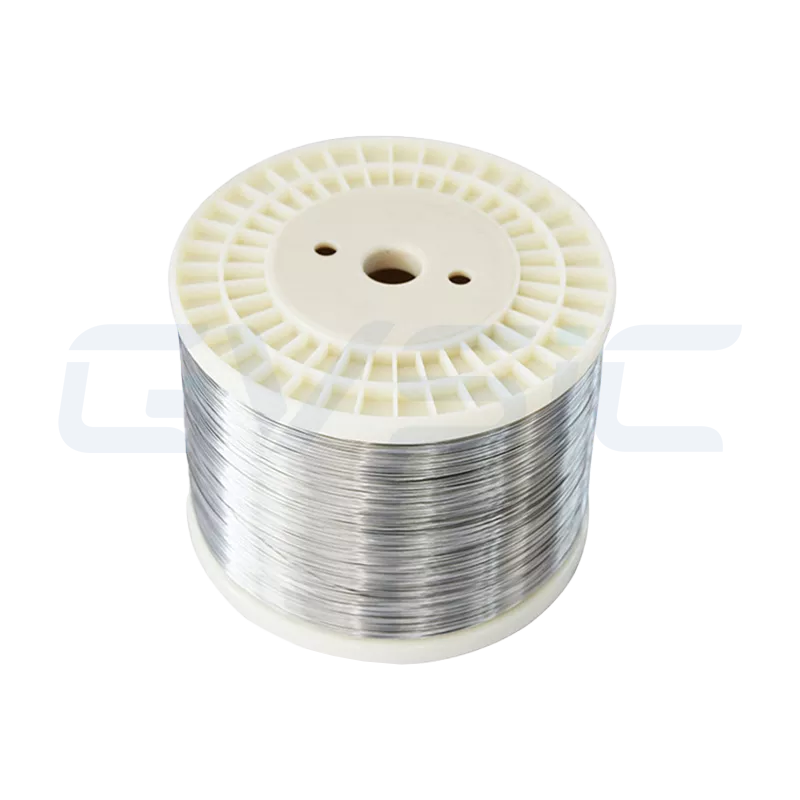

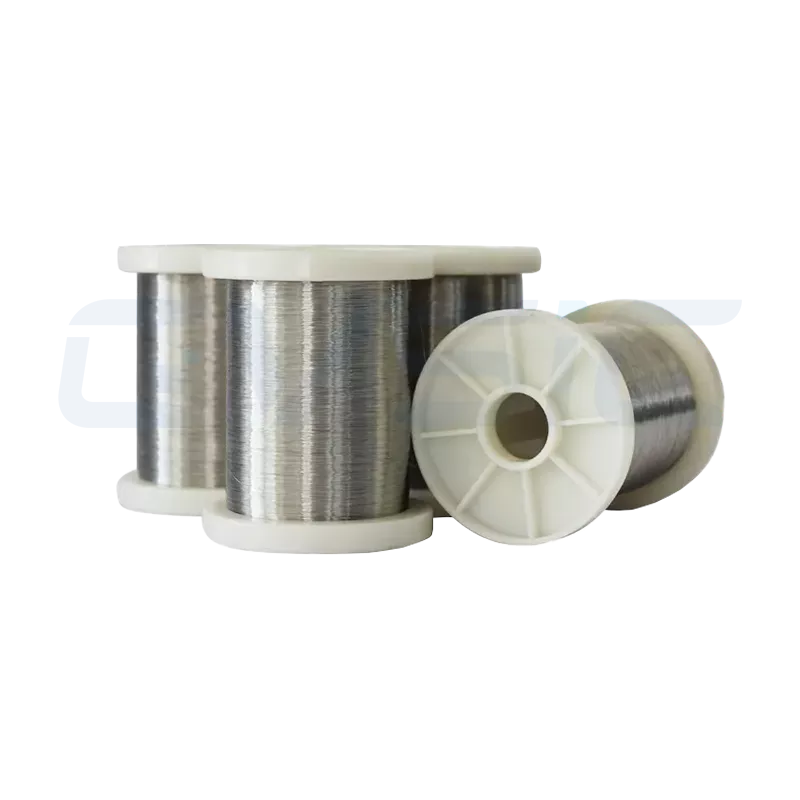

CVSIC 0Cr25Al5 Resistance Wire Custom & B2B Supply

We offer 0Cr25Al5 FeCrAl wire with:

- Custom diameters (0.1–7.0 mm)

- Cut-to-length or spool packaging

- OEM/ODM support for heating elements

- Reliable B2B wholesale for industrial buyers

FAQs

Can I just swap 0Cr25Al5 in for NiCr?

Yeah, but you will need to recalculate the length and power load.

It has got higher resistivity and different oxidation behavior, so do some quick engineering checks first.

What happens if I run a surface load that’s too high?

It speeds up grain growth and oxidation big time, which cuts the wire’s lifespan way shorter.

Is 0Cr25Al5 good in reducing atmospheres?

Nope—not recommended. It is best in plain air or mildly oxidizing setups.

0Cr25Al5 is one of the most battle-tested and popular high-temp resistance wires in the FeCrAl lineup. It nails the mix of staying stable at crazy heat, fighting oxidation, and just working great in real industrial apps—pretty much the standard pick for furnace heating systems.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 0Cr25Al5 Resistance Wire

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support