How to choose the right ceramic fiber product for your project?

Selecting the right ceramic fiber is crucial for high-temperature industries due to its thermal insulation and heat resistance.…

CVSIC Ceramic Fiber Heating Modules and Electric Heating Boards can withstand temperatures up to 1800°C, combining heating and insulation in one unit. They suit industrial furnaces, pipe heating, and lithium battery sintering. Custom sizes and packaging are available, with global wholesale supply. Contact us for efficient heating solutions!

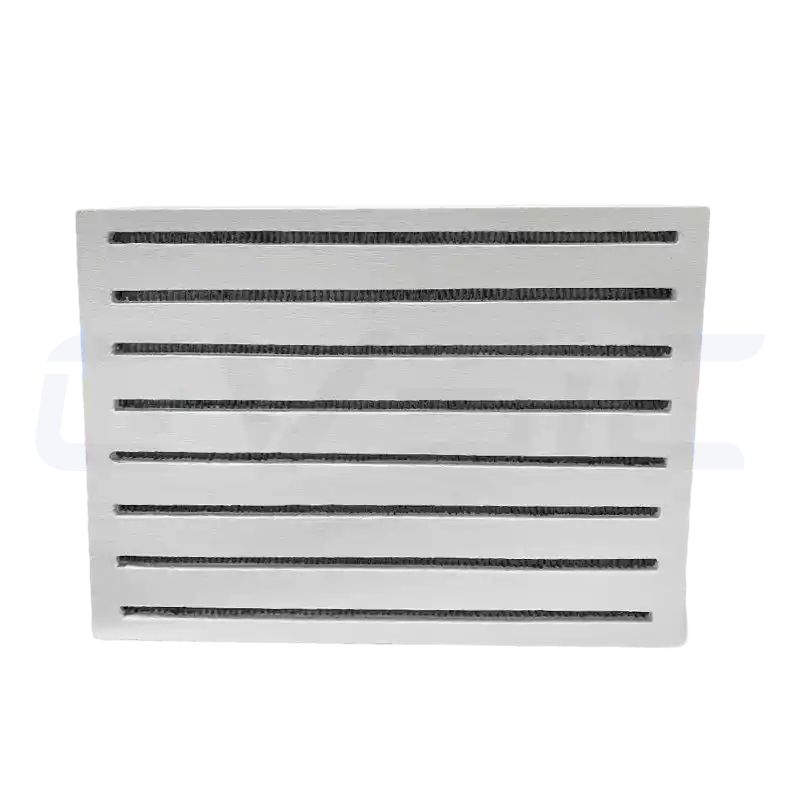

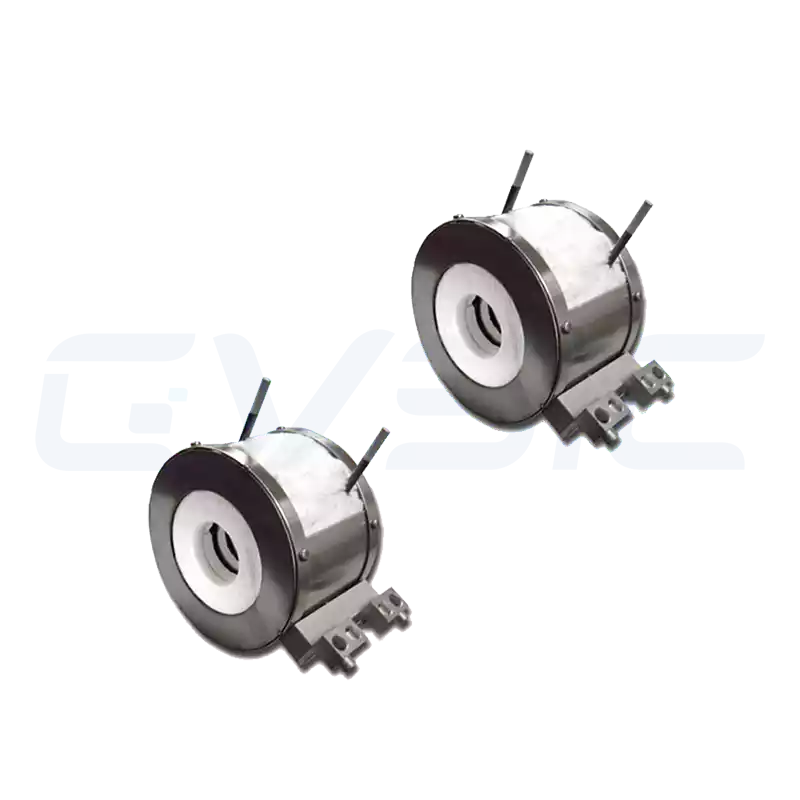

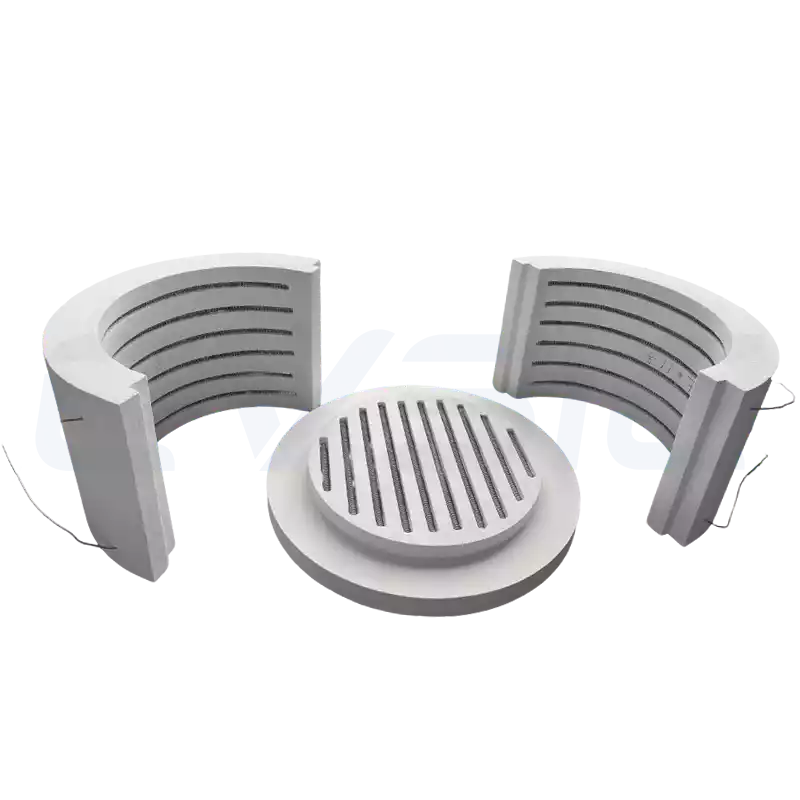

CVSIC ceramic fiber electric heating modules/electric heating plates are made of high-purity ceramic fiber and electric heating elements (such as resistance wire, silicon carbide, or molybdenum disilicide) through a special process, combining efficient heating and excellent insulation, eliminating the complexity of traditional electric heating wire suspension structures.

The product supports various installation methods, including embedded, semi-exposed, slot-mounted, and externally mounted configurations. The operating temperature range is 300-1300°C. When using silicon carbide or molybdenum disilicide heating elements, the maximum temperature resistance can reach 1800°C. The product series covers six temperature grades: 1260°C, 1400°C, 1500°C, 1600°C, 1700°C, and 1800°C, and is widely applied in industrial furnaces, pipe heaters, and lithium-ion battery sintering equipment.

CVSIC ceramic fiber electric heating modules/electric heating plates are widely used in the following fields:

CVSIC offers comprehensive customization services for ceramic fiber electric heating modules/heating plates to meet your specific requirements:

Contact us immediately to obtain customized solutions and quotes for CVSIC ceramic fiber electric heating modules/electric heating plates, and optimize your high-temperature heating and insulation applications!

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Selecting the right ceramic fiber is crucial for high-temperature industries due to its thermal insulation and heat resistance.…

In the world of high-temperature industries, heat is both a friend and a challenge. How can equipment maintain…

In high-temperature industries, selecting the right insulation material is akin to choosing the ‘best armour’ for equipment. As…

In high-temperature industries, equipment must operate steadily and efficiently while minimizing energy loss. Ceramic fiber meets these challenges…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support