Dental Furnaces: A Comprehensive Guide from Sintering Furnaces to Porcelain Furnaces

In dental clinics and laboratories, dental furnaces are essential pieces of equipment. Whether producing realistic all-ceramic crowns or…

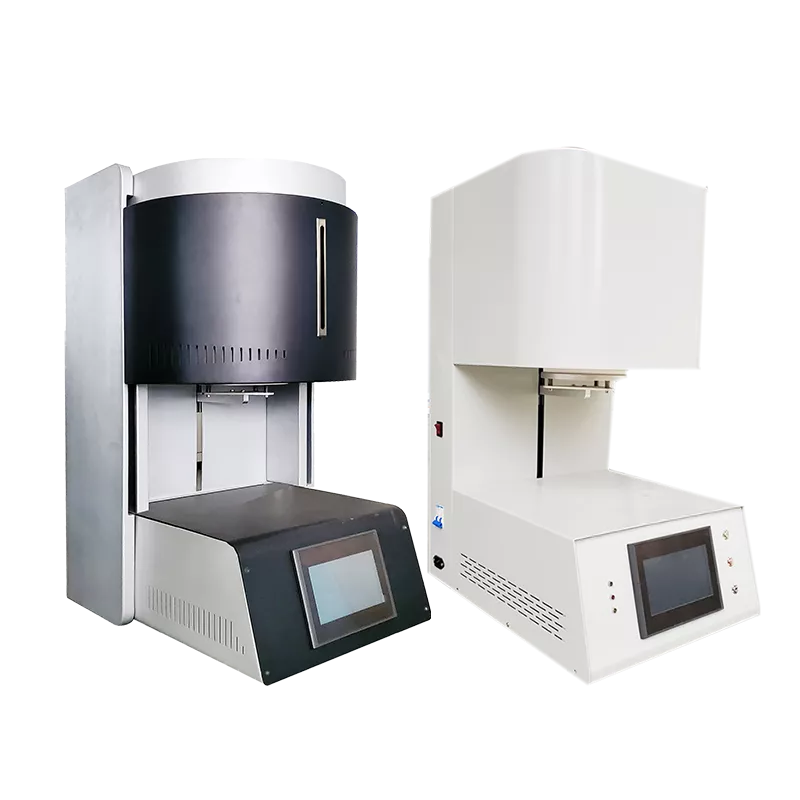

The CVSIC Plus Zirconia Sintering Furnace provides rapid, precise, and environmentally friendly zirconia sintering. Capable of processing 80 crowns in 90 minutes or 150 crowns per batch, it features a Japanese-imported pure chamber and MoSi₂ heating elements. Ideal for dental labs and manufacturers seeking efficiency and quality.

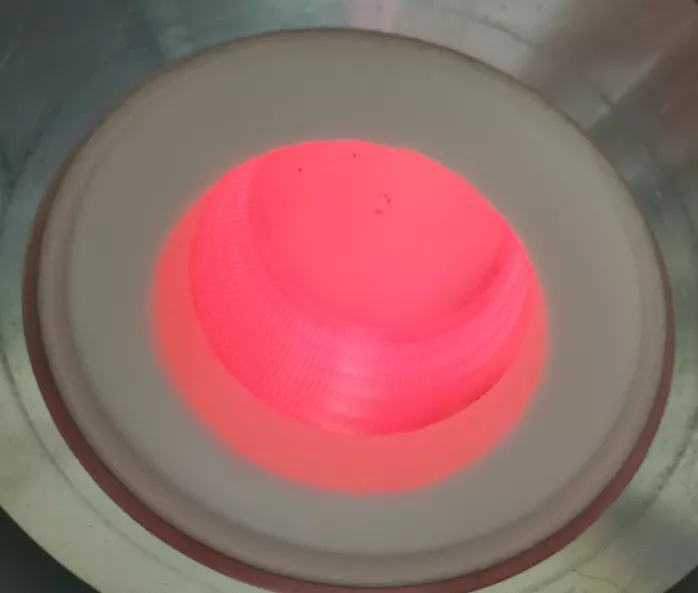

The CVSIC Zirconia Sintering Furnace Plus is the upgraded model of the CVSIC series, engineered to meet the high-output and precision requirements of modern dental laboratories and manufacturers. Equipped with a Japanese-imported alumina polycrystalline fibre furnace chamber and molybdenum disilicide heating elements, it ensures stable high-temperature performance and a contamination-free sintering environment up to 1700°C.

Its high capacity allows sintering of 150 crowns in one cycle, with fast sintering of 80 crowns in just 90 minutes, significantly improving productivity. With a fully automated control system and one-button start-up, the CVSIC Plus provides simple operation, energy savings, and consistent results.

Upgrade your dental laboratory or production line with the CVSIC Plus Zirconia Sintering Furnace — an efficient, precise, and eco-friendly solution. Contact CVSIC today for quotations, customization, or wholesale partnership opportunities.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

In dental clinics and laboratories, dental furnaces are essential pieces of equipment. Whether producing realistic all-ceramic crowns or…

Introduction: Temperature and Materials—The Fundamental Principles of Sintering Furnaces The creation of high-quality restorations is significantly influenced by…

Introduction: Choosing the Ideal Sintering Furnace for Your Dental Laboratory As an engineer, I recognize how the appropriate…

In dental labs, furnaces are essential tools for creating restorations, with sintering and porcelain furnaces being the two…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support