H-Type SiC Heating Elements

H-Type SiC Heater, Rods, Elements

CVSIC H-type silicon carbide heating element (SiC rod) handles up to 1625°C (2957°F), works with 8-65mm sizes, and resists corrosion and oxidation, with a 2000-hour lifespan. Offering global wholesale, customization, and OEM/ODM services. Contact us for free samples!

- Product Name: H-Type Silicon Carbide Heating Element (SiC Rod)

- Material: High-purity green hexagonal silicon carbide (SiC)

- Components: Aluminum braid, H-type stainless steel clamp (M-type clip)

- Diameter: 8-65mm (cold end/hot end)

- Temperature: Up to 1625℃ (oxidizing atmosphere)

- Voltage: 110-480V

- Appearance: Gray-green rod, smooth surface

- Packaging: Carton or export wooden crate

- Lifespan: Up to 2000 hours of continuous use

H-Type SiC Heater Description

H-type silicon carbide heating element (also called SiC rod) is a non-metal electric heating element made from high-purity green hexagonal silicon carbide, sintered at 2200℃ through high-temperature silicification and recrystallization, built for high-temp furnaces and industrial heating.

Its H-type design, paired with aluminum braids and H-type clamps (M-type clips), ensures solid conductivity and secure fixation, making it ideal for oxidizing atmospheres that reach up to 1625°C (2957°F) with a 2000-hour continuous lifespan.

It offers resistance to extreme heat, oxidation, and corrosion, heats up quickly, retains its shape, and is easy to install and maintain, making it a go-to choice for ceramics, semiconductors, glass, metallurgy, and various research applications. Paired with an automated power supply, it delivers precise, constant temperature control or automatically adjusts according to process curves.

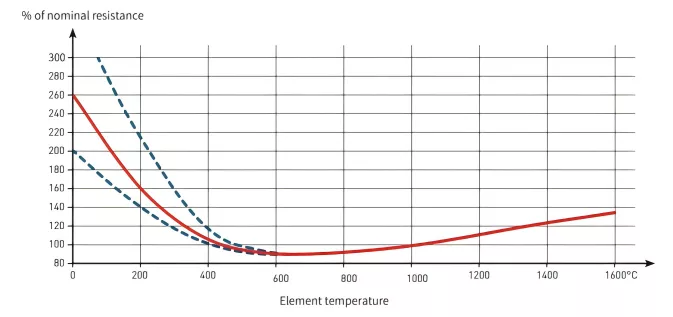

SiC Heating Elements ResistanceTemperature Performance Graphs

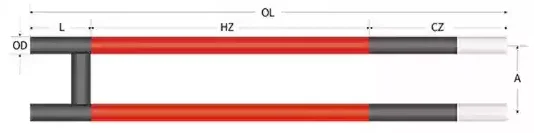

H Type SiC Rods Ordering Information

When ordering H-type silicon carbide heating elements, please provide the following parameters:

- Diameter: Cold end/hot end diameter (8-65mm)

- Length: Hot zone (HZ), cold zone (CZ), total length

- Resistance: As per circuit design

- Example: H-type SiC rod, diameter 14/25mm, hot zone length 400mm, cold zone length 250mm, resistance 8Ω

Note: Custom specs are available to ensure perfect compatibility with furnace designs.

H Type SiC Rods Connection Method

- Installation Position: The H-type clamp (M-type clip) with aluminum braid is fixed to the SiC rod’s cold end at its outermost point, ensuring tight contact with the aluminum coating.

- Connection Method:

- Place the aluminum braid on the SiC rod’s cold-end aluminum coating.

- Secure the aluminum braid around the cold end with the H-type stainless steel clamp (M-type clip) using screws.

- Verify that the clamp’s diameter marking (8-65mm) matches the diameter of the SiC rod.

- Connect to the power source, ensuring connection end voltage <0.01V for solid electrical contact.

- After 2-3 hours of furnace operation, re-tighten screws to address thermal relaxation.

- Note:

- Avoid over-compression during installation to prevent damage to the SiC rod.

- Keep cold end temperature <300℃ to avoid overheating and connection failure.

- Use an SCR voltage regulator (for precise current control) to extend the element’s lifespan.

H Type SiC Elements Application Fields

CVSIC H-type silicon carbide heating elements are widely used in:

- Ceramics Industry: For high-temp sintering in tunnel kilns, roller kilns, and muffle furnaces.

- Electronic Semiconductors: Supports heating for wafer sintering, diffusion furnaces, and encapsulation processes.

- Glass Industry: Used in glass kilns and annealing furnaces for precise heating.

- Metallurgy: Provides stable heating for metal heat treatment and smelting furnaces.

- Scientific Research: Meets heating needs for lab high-temp furnaces and analytical testing equipment.

- Defense, Mechanical, and Light Industries: Offers reliable high-temp heating solutions.

CVSIC H Type SiC Rods Product Advantages

- Handles Extreme Heat Like a Pro: Operates up to 1625°C (2957°F) in oxidizing atmospheres, with a 2000-hour lifespan.

- Oxidation and Corrosion Resistance: High-purity SiC material thrives in harsh environments.

- Rapid Heating: Great thermal conductivity heats up fast, boosts efficiency, and saves energy.

- Minimal Deformation: Stays structurally stable at high temps, keeping its shape.

- Easy Installation and Maintenance: The H-type clamp and aluminum braid design simplify setup, resulting in low maintenance costs.

- Chemical Stability: Works with various atmospheres, perfect for complex process environments.

- Stock Availability: Standard specs ship in 2-3 days; custom specs delivered in 7-30 days.

- Global Service: ISO-certified factory, 360-ton annual capacity, offers free samples with no minimum order quantity.

H Type SiC Heater Installation Method

To ensure the performance and safety of H-type silicon carbide heating elements, follow these steps:

- Inspect Components: Check that the SiC rod, H-type clamp (M-type clip), and aluminum braid are undamaged, and verify that the diameter markings match the element.

- Secure Cold End: Place the aluminum braid on the aluminum coating of the cold end, using the H-type clamp to secure it with screws.

- Vertical/Horizontal Installation: Install the SiC rod vertically or horizontally per furnace design, ensuring no mechanical stress and keeping clearance (≥3 times hot end diameter) from furnace walls.

- Power Connection: Connect the power source via the aluminum braid, ensuring good contact and connection end voltage <0.01V.

- Initial Operation: After 2-3 hours of furnace operation, re-tighten clamp screws to address thermal relaxation.

- Maintenance Check: Regularly check clamp and screw tightness to prevent loosening or damage from overheating.

- Note: Installation must be performed by professionals, avoiding striking or over-compressing the SiC rod to prevent damage. For detailed guidance, please get in touch with us.

H Type SiC Elements Design Recommendations

- Diameter Matching: Choose an H-type clamp matching the cold end diameter (8-65mm), verifying marked numbers.

- Cold End Length: Design cold end length (Le) based on furnace depth, keeping cold end temperature <300℃.

- Resistance Matching: Select appropriate resistance based on circuit design to avoid overloading or underloading.

- Installation Space: Keep clearance (≥3 times hot end diameter) from furnace walls/bottom to prevent localized overheating.

- Temperature Control: Use an SCR voltage regulator (for precise current control) to extend the element’s lifespan.

- Regular Maintenance: Check clamp and screw tightness after 2-3 hours of initial operation to prevent loosening or corrosion that may affect performance.

CVSIC H Type SiC Rods Customization Services

CVSIC offers flexible customization for H-type silicon carbide heating elements:

- Size Customization: Tailored to diameter (8-65mm), length, and resistance, with matching clamps.

- OEM/ODM Services: Support bulk wholesale, free samples, no minimum order quantity, and delivery in 7-30 days.

- Special Coatings: Offer oxidation- or corrosion-resistant coatings for better high-temp performance.

- Technical Support: Provide expert guidance and thermal field simulation from selection to setup.

- Contact us for customized solutions or free samples!

CVSIC is committed to delivering top-notch H-type SiC heating elements to optimize heating performance in high-temp furnaces, ceramics, semiconductors, and more. Contact us for product quotes, customization services, or free samples to boost your heating efficiency!

H Type SiC Elements Accessories

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To H-Type SiC Heating Elements

DB Type SiC Heater Rods

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: DB Type

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

Straight (ED type) SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: ED/Straight/ROD/RR/GD

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

U-Type SiC Heating Elements

- Material: High-purity silicon carbide (SiC), ≥99% content

- Shape: U-Shaped SiC Heating Element

- Power Supply: 220V/380V

- Manufacturing Process: High-quality silicon carbide blank, high-temperature silicon carbide recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625℃

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

W-Type SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Shape: W-Type SIC Heating Rods

- Power Supply: 110-480V electric

- Manufacturing Process: High-quality SiC billet, high-temperature silicification recrystallization

- Diameter: 12-55mm

- Operating Temperature: Up to 1625℃

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

SG Type SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Shape: SS/SC/LD

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

SCR SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: SD/SCR/LS

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

Slot type (UX) SiC Heating Element

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: Slot type (UX-Type) SiC Heater

- Power Supply: 110-480V electric

- Manufacturing Process: High-quality SiC billet, high-temperature silicification recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

- Brand: CVSIC

H-Type SiC Heating Elements Relate News

How to Choose SiC Heating Elements: A Buyer’s Guide

In high-temperature industrial settings, such as ceramic firing, metal heat treatment, or semiconductor production, Silicon Carbide Heating Elements…

Kanthal vs CVSIC: SIC & MoSi2 Heating Element Comparison

In the realm of high-temperature industrial heating, silicon carbide and molybdenum disilicide heating elements are the primary materials…

Silicon Carbide Rod Uses, Advantages & CVSIC Heating Element Excellence

Imagine a high-temperature industrial setting: a ceramic plant’s tunnel kiln operating 24/7, a semiconductor production line requiring precise…

Silicon Carbide VS Molybdenum Disilicide Elements: Differences and Selection Guide

In high-temperature industrial settings, whether it’s kiln firing in ceramic factories, semiconductor crystal growth, or new energy battery…

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support