Straight (I-Type) MoSi2 Heating Elements

I-Type MoSi2 Heater, Rods, Elements

CVSIC Straight (I-Type) Molybdenum Disilicide (MoSi2) heating element, up to 1900℃, oxidation-resistant and high-temperature, perfect for ceramics, electronics, lithium batteries, and high-temp furnaces. Offering global wholesale, customization, and OEM/ODM services. Contact us for free samples!

- Material: Molybdenum Disilicide (MoSi2)

- Shape: Straight/I-Type

- Power Supply: 220-480V

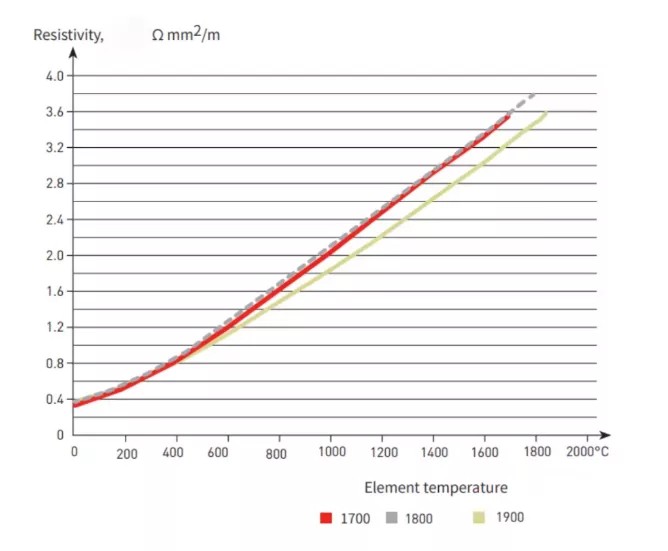

- Grade: 1700/1800/1900

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

Straight Type MoSi2 Heater Description

CVSIC Straight (I-Type) Molybdenum Disilicide (MoSi2) heating element, with a linear design, is crafted from high-purity MoSi2 through a high-temperature sintering process, boasting a density of 5.5-6.2 g/cm³ and a maximum operating temperature of 1900℃. Its high-density structure and advanced welding technology deliver top-notch oxidation resistance, rapid heating, and strong mechanical strength, making it a budget-friendly heating option for high-temperature furnaces and demanding environments. It’s widely used in ceramics, electronics, lithium batteries, and high-temperature heat treatment industries.

Ordering Information

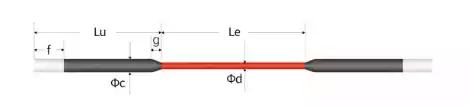

When ordering Straight (I-Type) MoSi2 heating elements, please provide the following parameters:

- Material Grade: 1700/1800/1900

- d/c: Hot zone/cold zone diameter (mm)

- Le: Hot zone length (mm)

- Lu: Cold zone length (mm)

- Example: I-Type, 1800 grade, d/c=6/12mm, Le=400mm, Lu=300mm, denoted as: 1800/I-Type/6/12x400x300

Note: For additional specifications or custom options, please get in touch with us.

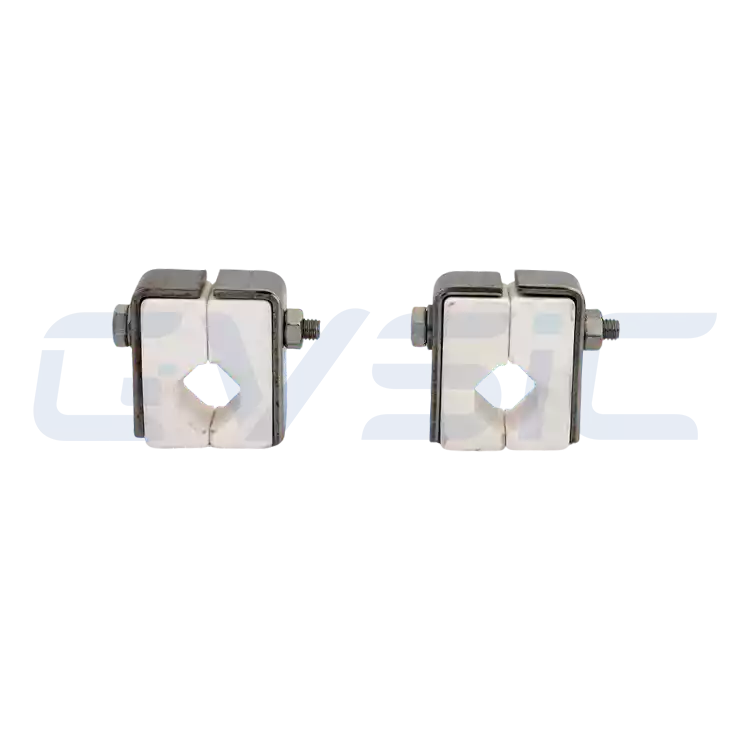

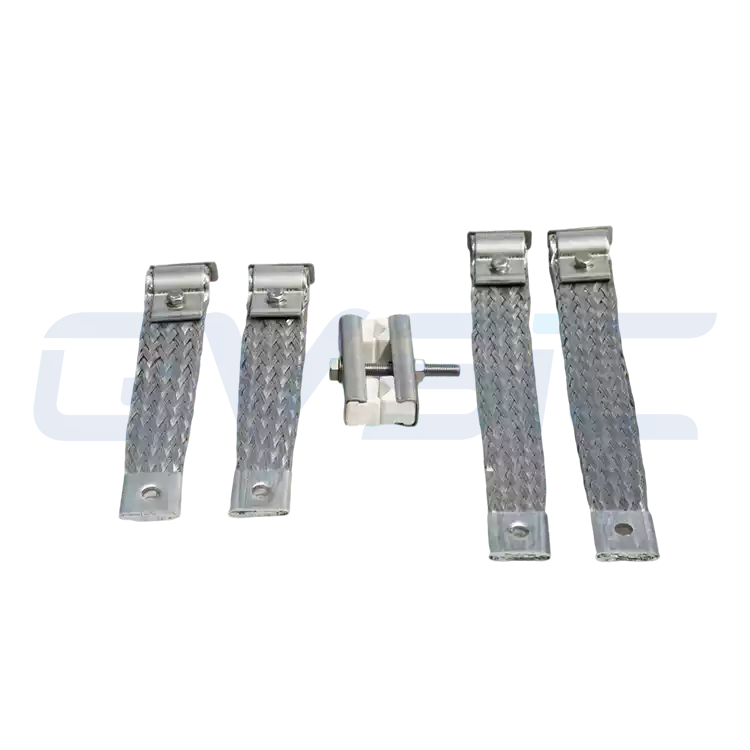

Straight Type MoSi2 Rods Connection Method

- Contact Surface Design: The cold end features an aluminum coating, ensuring low-resistance contact for efficient conductivity.

- Electrical Connection: Secure with flat aluminum braid and spring clips, compatible with 220-480V power; use an SCR voltage regulator (for precise temperature control) for best results.

- Note: Ensure connectors fit snugly to the cold end, with connection end voltage <0.01V; pick the right material grade (1700/1800/1900) based on atmosphere type.

Straight Type MoSi2 Elements Application Fields

CVSIC Straight MoSi2 heating elements are widely used in:

- High-Temperature Furnaces: Supports ceramic sintering, glass manufacturing, and other high-temperature processes.

- Electronic Semiconductors: Used for wafer sintering, diffusion furnaces, and encapsulation material heating.

- Lithium Battery Materials: Facilitates high-temp processing of battery anode and cathode materials.

- Rare Earth Phosphors and Precision Casting: Provides high-temp stability and uniform heating.

- Laboratory Furnaces: Meets high-temp experimental and material testing needs.

Straight Type MoSi2 Rods Product Advantages

- Ultra-High Temperature Resistance: Operates up to 1900℃, perfect for extreme environments.

- Self-Healing Oxidation Resistance: High-density MoSi2 (5.5-6.2 g/cm³) ensures excellent oxidation resistance for long-term use in oxidizing atmospheres.

- Quick and Uniform Heating: 4% thermal elongation provides even temperature fields, rapid heating, and reduced energy consumption.

- High Mechanical Strength: The bending strength of 15-25 kg/cm², combined with advanced welding technology, enhances impact resistance, reducing damage risks during transport and setup.

- Flexible Customization: Supports custom shapes and sizes to fit complex furnace designs.

- Corrosion Resistance: Low porosity (7.4%) and water absorption (0.2%) make it suitable for various atmospheres (air, inert gases, etc.), enhancing its durability.

- Global Service: ISO-certified factory, 360-ton annual capacity, offers free samples, and 7-30 day delivery.

Straight Type MoSi2 Elements Installation Method

To ensure the performance and safety of Straight MoSi2 heating elements, follow these steps:

- Inspect Element: Check for cracks or damage before setup.

- Installation Position: Place the cold end in the furnace, keeping the hot end centered in the chamber at an adequate distance from the furnace walls and bottom (at least three times the diameter of the hot end).

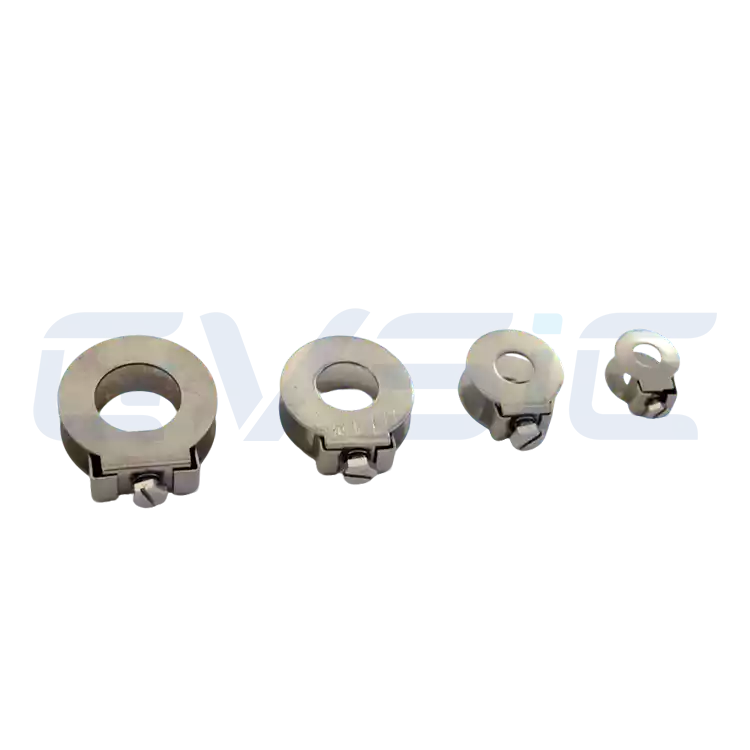

- Fixing Device: Use ceramic or heat-resistant steel clips to secure cold ends, avoiding mechanical stress.

- Power Connection: Connect the cold end to power using a flat aluminum braid and spring clips, ensuring a solid connection.

- Preheating: Gradually ramp up power during first use to avoid thermal shock.

- Regular Maintenance: Check connectors and clips for loosening or corrosion; re-tighten screws after 2-3 hours of operation to handle thermal relaxation.

Replacement Steps

- Locate the damaged element and prepare a replacement set.

- Disconnect the power, remove the aluminum braid and connecting screws, and clear the refractory material and plugs.

- Insert a new element from the furnace top, reconnect the wires, and refill the refractory material.

- Gradually heat to ensure regular operation.

Note: Professionals should perform installations and replacements. Contact us for detailed guidance.

Straight Type MoSi2 Heater Design Recommendations

To optimize the performance of Straight MoSi2 heating elements, follow these suggestions:

- Length Matching: Ensure Lu (150-1000mm) and Le (150-1500mm) match furnace dimensions, avoiding hot end insertion into furnace walls.

- Atmosphere Selection: Select a grade of 1700/1800/1900 based on the atmosphere (e.g., O2, N2, H2), referring to the maximum temperature table.

- Spacing Design: Maintain a clearance of at least three times the hot end diameter between the element and the furnace walls/materials and at least four times the diameter for center-to-center spacing to optimize heat distribution.

- Temperature Control System: Utilize a PID controller for precise temperature control to prolong the element’s lifespan.

- Cold End Protection: Ensure the cold end aluminum coating is intact and that the connectors are tightly secured to prevent poor contact.

Customization Services

CVSIC offers flexible customization for Straight (I-Type) MoSi2 heating elements:

- Size Customization: Adjust hot/cold zone diameter and Lu/Le length.

- Grade Selection: Offer 1700/1800/1900 grades to suit different atmospheres and temperature needs.

- Special Coatings: Offer oxidation-resistant coatings for enhanced performance in demanding environments.

- OEM/ODM Services: Support bulk wholesale, free samples, no minimum order quantity, and 7-30 day delivery.

- Technical Support: Offer expert guidance and thermal simulation for selection and setup.

- Contact us for customized solutions or free samples!

CVSIC is dedicated to providing top-notch I-Type MoSi2 heating elements to optimize ceramics, electronics, lithium batteries, and high-temperature processes. Contact us for product quotes and customization services or to request free samples that can help enhance your heating efficiency.

I Type MoSi2 Elements Accessories

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Straight (I-Type) MoSi2 Heating Elements

W Shape MoSi2 Heating Elements

- Material: Molybdenum Disilicide (MoSi2)

- Shape: W-Type

- Power Supply: 220-480V

- Grade: 1700/1800/1850

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

U Shape MoSi2 Heating Rod

- Material: Molybdenum Disilicide (MoSi2)

- Power Supply: 220-480V

- Grade: 1700/1800/1850

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

L Shape Molybdenum Disilicide Rod

- Product Specifications

- Material: Molybdenum Disilicide (MoSi2)

- Shape: L-Type

- Power Supply: 220-480V

- Grade: 1700/1800/1850

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

Straight (I-Type) MoSi2 Heating Elements Relate News

MoSi2 Heating Elements: Introduction and Applications

Imagine you’re running a ceramic factory where the tunnel kiln must operate steadily at 1450°C, and any downtime…

Kanthal vs CVSIC: SIC & MoSi2 Heating Element Comparison

In the realm of high-temperature industrial heating, silicon carbide and molybdenum disilicide heating elements are the primary materials…

Silicon Carbide VS Molybdenum Disilicide Elements: Differences and Selection Guide

In high-temperature industrial settings, whether it’s kiln firing in ceramic factories, semiconductor crystal growth, or new energy battery…

High-Temperature Characteristics of MoSi2 Heater

Imagine you’re running a ceramic factory where the kiln must operate continuously at 1700°C, and any failure of…

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support