Comprehensive Guide to Tube Furnaces: Types, Principles, and Applications

What is a Tube Furnace? Your Gateway to High-Temperature Applications Tube furnaces are essential high-temperature heating systems widely…

High-temperature vertical tube furnace with options up to 1600°C. Supports high vacuum (7×10⁻⁴ Pa), inert gas, and oxidizing atmospheres. Ideal for ceramics, battery materials, CVD, and powder metallurgy. Custom sizes and heating elements available. Global support.

The CVSIC Vertical Tube Furnace is a high-precision heating system designed for controlled-atmosphere or high-vacuum processes. Operating at temperatures from 1200°C to 1600°C, it is ideal for sintering, vapor deposition, brazing, and thermal treatment of ceramics, battery materials, and metallic powders.

Available with high-purity quartz (1200°C) or alumina tubes (1400°C/1600°C), the system features a vertically aligned design, offering precise temperature uniformity, rapid thermal response, and exceptional safety. A double-layer shell with air cooling ensures operator protection. The system can be configured with resistance wire, SiC rods, or MoSi2 rods to suit different thermal profiles.

Contact CVSIC to discuss your ideal furnace configuration and receive a tailored solution.

Note: All models can be customized. For complete specification sheets or consultation, please contact us.

Looking for a vertical tube furnace that meets your exact needs? CVSIC offers full customization, global support, and unmatched quality.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

What is a Tube Furnace? Your Gateway to High-Temperature Applications Tube furnaces are essential high-temperature heating systems widely…

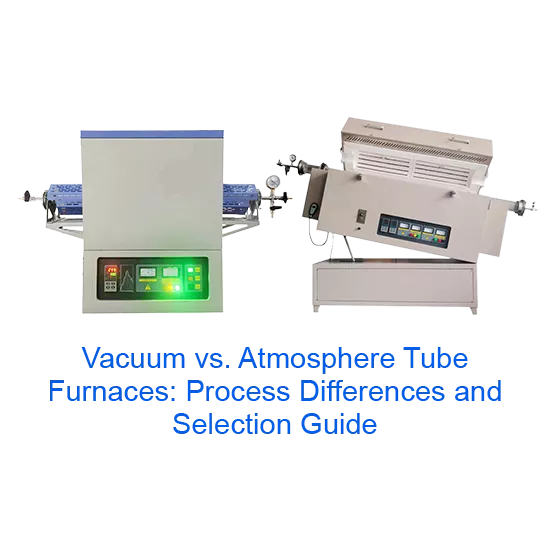

Vacuum vs. Atmosphere Tube Furnaces: Selecting the Optimal Equipment for Your Experiments Sample oxidation or contamination in high-temperature…

Rotary vs. Fixed Tube Furnaces: Choosing the Ideal Solution for Your Process When processing powder materials, issues like…

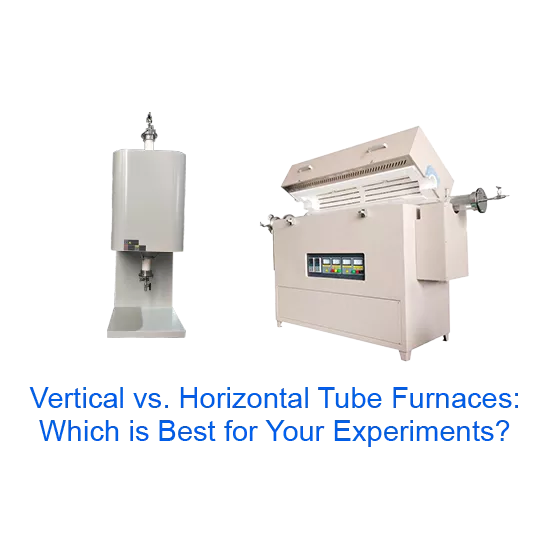

Vertical vs. Horizontal Tube Furnaces: Choosing the Right Equipment for Your Needs When selecting tube furnaces for materials…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support