W Shape MoSi2 Heating Elements

W Shape MoSi2 Heater, Rods, Bar

CVSIC W-Type Molybdenum Disilicide (MoSi2) heating element, up to 1850℃, high-temperature and oxidation-resistant, great for ceramics, electronics, lithium batteries, and big high-temp furnaces. Offering global wholesale, customization, and OEM/ODM services. Contact us for free samples!

- Material: Molybdenum Disilicide (MoSi2)

- Shape: W-Type

- Power Supply: 220-480V

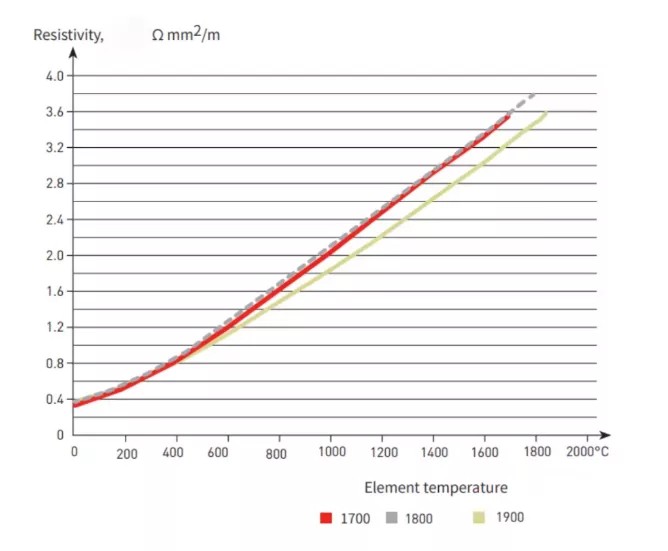

- Grade: 1700/1800/1850

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

W Shape MoSi2 Heater Description

CVSIC W-Type Molybdenum Disilicide (MoSi2) heating element, shaped like a “W,” is crafted from high-purity MoSi2 using advanced hot-bending technology and a unique formula, with a density of 5.5-6.2 g/cm³ and a maximum operating temperature of 1850℃. Its “three U-shaped” design boasts uniform curvature, wide center spacing, and high hot-end density, making it ideal for horizontal setup in large electric kilns. Aluminum-coated cold ends ensure strong conductivity, while a special surface coating boosts thermal shock resistance and lifespan. It works great for ceramics, electronics, lithium batteries, and high-temperature processing.

Ordering Information

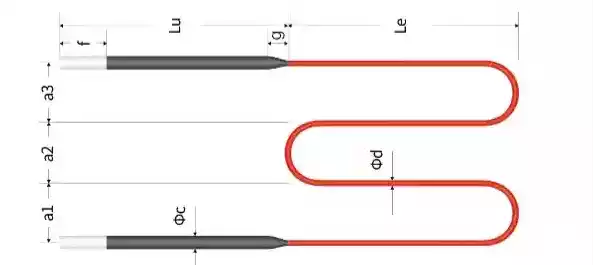

When ordering W-Type MoSi2 heating elements, please provide the following parameters:

- Material Grade: 1700/1800/1850

- d/c: Hot zone/cold zone diameter (mm)

- Le: Hot zone length (mm)

- Lu: Cold zone length (mm)

- A: Shank spacing (mm)

- Example: W-Type, 1800 grade, d/c=3/6mm, Le=140mm, Lu=125mm, A=25mm, denoted as: 1800/W-Type/3/6x140x125x25

Note: For additional specifications or custom options, please get in touch with us.

W Shape MoSi2 Rod Connection Method

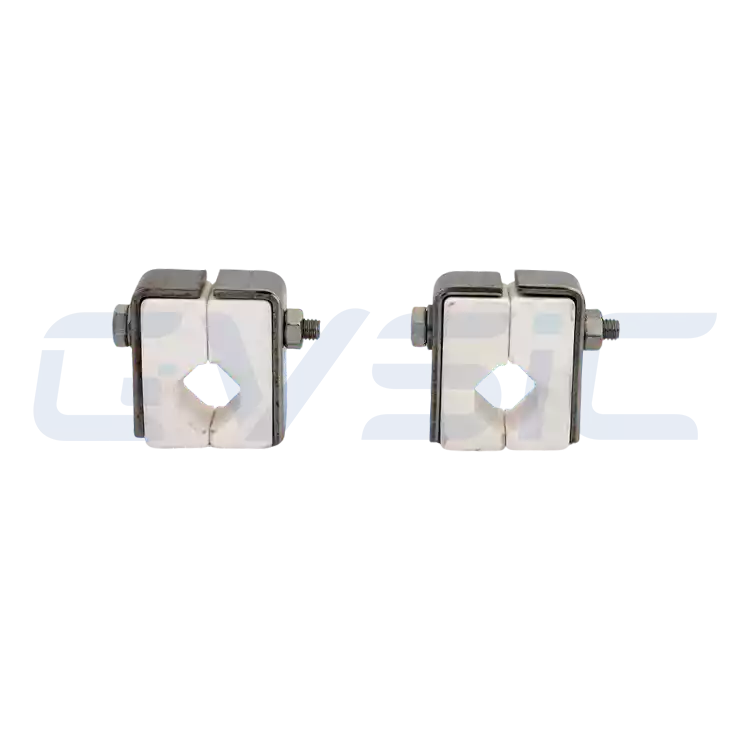

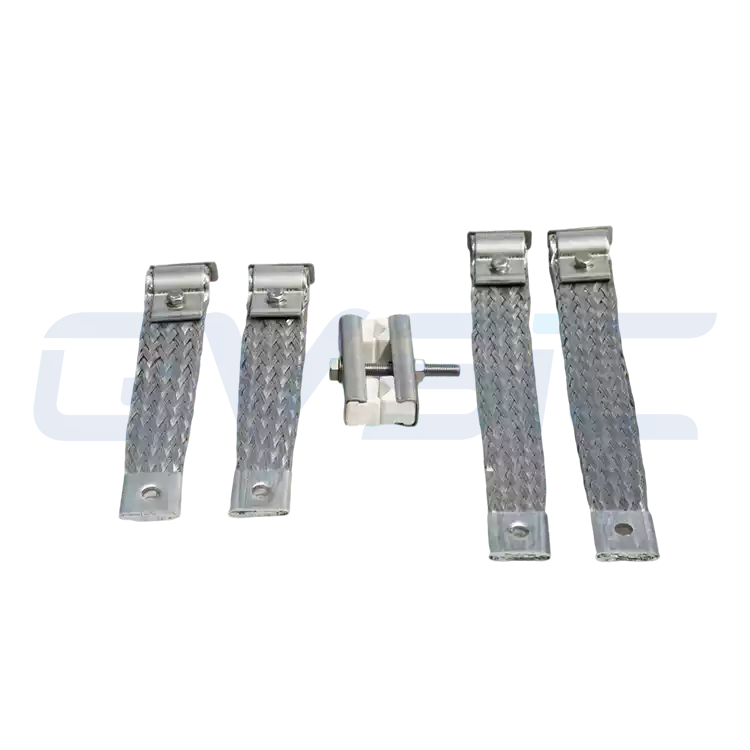

- Contact Surface Design: Both cold ends are aluminum-coated for low-resistance contact and efficient conductivity.

- Electrical Connection: Secure with flat aluminum braid and spring clips, compatible with 220-480V power; use an SCR voltage regulator (for precise temperature control) for best results.

- Note: Ensure connectors fit snugly to the cold end, with connection end voltage <0.01V; pick the right material grade (1700/1800/1850) based on atmosphere type.

W Shape MoSi2 Elements Application Fields

CVSIC W-Type MoSi2 heating elements are widely used in:

- Large High-Temperature Furnaces: Supports ceramic sintering, glass manufacturing, and high-density layout processes.

- Electronic Semiconductors: Used for wafer sintering, diffusion furnaces, and encapsulation material heating.

- Lithium Battery Materials: Facilitates high-temperature processing of battery anode and cathode materials.

- Rare Earth Phosphors and Precision Casting: Provides high-temperature stability and uniform heating.

- Laboratory Furnaces: Meets high-temperature experimental and material testing needs.

CVSIC W Shape MoSi2 HeaterProduct Advantages

- Ultra-High Temperature Resistance: Operates up to 1850 °C, ideal for extreme environments.

- High Oxidation Resistance: High-density MoSi2 (5.5-6.2 g/cm³) with a special coating ensures top-notch oxidation resistance and long lifespan.

- Quick and Consistent Heating: 4% thermal elongation delivers even temperature fields, fast heating, and shorter furnace warm-up times.

- Thermal Shock Resistance: The W-Type “three U-shaped” design, with uniform curvature, offers substantial creep and thermal shock resistance.

- Energy Efficiency: Wide center spacing and high hot-end density reduce wiring and cut cold/hot-end interface losses.

- Corrosion Resistance: Low porosity (7.4%) and water absorption (0.2%) make it suitable for various atmospheres, enhancing its durability.

- Stable Resistivity: Resistivity remains constant over time, enabling the mixed use of new and old elements.

- Global Service: ISO-certified factory, 360-ton annual capacity, offers free samples, and 7-30 day delivery.

W Shape MoSi2 Bar Installation Method

To ensure the performance and safety of W-Type MoSi2 heating elements, follow these steps:

- Inspect Element: Check for cracks or damage before setup to ensure the surface coating is intact.

- Installation Position: Set up horizontally, with three U-shaped bends supported by corundum spacer bricks, and insert cold ends into the furnace, keeping the transition zone unexposed to avoid overheating damage.

- Spacing Design: Maintain adequate distance from furnace walls and materials (at least 3 times the hot end diameter) to prevent heat buildup.

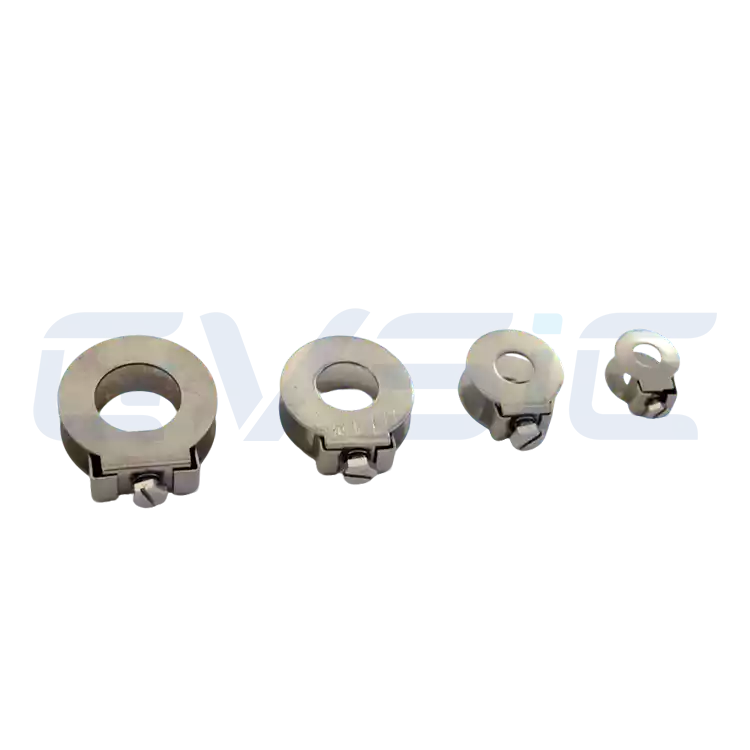

- Fixing Device: Use ceramic or heat-resistant steel clips to secure cold ends, with corundum spacer bricks supporting the three U-shaped bends to avoid mechanical stress.

- Power Connection: Connect the cold end to power with a flat aluminum braid and spring clips, ensuring solid contact and voltage <0.01V.

- Preheating: Gradually ramp up power during first use to avoid thermal shock.

- Regular Maintenance: After 2-3 hours of operation, check and re-tighten the connection screws to account for thermal relaxation. Regularly inspect the clips and corundum spacer bricks for stability.

Replacement Steps

- Locate the damaged element and prepare a replacement set.

- Disconnect the power, remove the aluminum braid and connecting screws, and clear the refractory material and plugs.

- Insert a new element from the furnace top, ensuring the corundum spacer bricks are correctly placed. Reconnect the wires and refill the refractory material.

- Gradually heat to ensure regular operation.

Note: Professionals should perform installations and replacements. Contact us for detailed guidance.

W Shape MoSi2 Rod Design Recommendations

To optimize the performance of W-Type MoSi2 heating elements, follow these suggestions:

- Length Matching: Ensure Lu (150-1000mm) and Le (150-1500mm) match furnace dimensions, avoiding hot end insertion into furnace walls.

- Shank Spacing Design: Choose a value (standard or minimum) based on diameter for optimal hot-end density and stability.

- Atmosphere Selection: Pick 1700/1800/1850 grade based on atmosphere (e.g., O2, N2, H2), referring to the maximum temperature table.

- Spacing Design: Maintain a clearance of at least three times the hot end diameter between the element and furnace walls/materials and at least four times the diameter for center-to-center spacing to optimize heat distribution.

- Temperature Control System: Utilize a PID controller for precise temperature control to prolong the element’s lifespan.

- Support Design: Use corundum spacer bricks to support the three U-shaped bends, ensuring even load distribution to prevent deformation.

Customization Services

CVSIC offers flexible customization for W-Type MoSi2 heating elements:

- Size Customization: Adjust hot/cold zone diameter, Lu/Le length, and shank spacing (A).

- Grade Selection: Offer 1700/1800/1850 grades to suit different atmospheres and temperature needs.

- Special Coatings: Offer oxidation-resistant coatings for enhanced performance and extended lifespan in demanding environments.

- OEM/ODM Services: Support bulk wholesale, free samples, no minimum order quantity, and 7-30 day delivery.

- Technical Support: Offer expert guidance and thermal simulation for selection and setup.

- Contact us for customized solutions or free samples!

CVSIC is focused on providing top-notch W-Type MoSi2 heating elements to optimize ceramics, electronics, lithium batteries, and extensive high-temperature furnace processes. Contact us for product quotes and customization services or to request free samples that can help enhance your heating efficiency.

W Type MoSi2 Elements Accessories

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To W Shape MoSi2 Heating Elements

Straight (I-Type) MoSi2 Heating Elements

- Material: Molybdenum Disilicide (MoSi2)

- Shape: Straight/I-Type

- Power Supply: 220-480V

- Grade: 1700/1800/1900

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

U Shape MoSi2 Heating Rod

- Material: Molybdenum Disilicide (MoSi2)

- Power Supply: 220-480V

- Grade: 1700/1800/1850

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

L Shape Molybdenum Disilicide Rod

- Product Specifications

- Material: Molybdenum Disilicide (MoSi2)

- Shape: L-Type

- Power Supply: 220-480V

- Grade: 1700/1800/1850

- Diameter: 3/6, 4/9, 6/12, 9/18, 12/24 mm or custom

- Density: 5.5-6.2 g/cm³

- Bending Strength: 15-25 kg/cm³

- Vickers Hardness: 570 kg/mm²

- Porosity: 7.4%

- Water Absorption: 0.2%

- Thermal Elongation: 4%

W Shape MoSi2 Heating Elements Relate News

High-Temperature Characteristics of MoSi2 Heater

Imagine you’re running a ceramic factory where the kiln must operate continuously at 1700°C, and any failure of…

MoSi2 Heating Elements: Introduction and Applications

Imagine you’re running a ceramic factory where the tunnel kiln must operate steadily at 1450°C, and any downtime…

Kanthal vs CVSIC: SIC & MoSi2 Heating Element Comparison

In the realm of high-temperature industrial heating, silicon carbide and molybdenum disilicide heating elements are the primary materials…

Silicon Carbide VS Molybdenum Disilicide Elements: Differences and Selection Guide

In high-temperature industrial settings, whether it’s kiln firing in ceramic factories, semiconductor crystal growth, or new energy battery…

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support