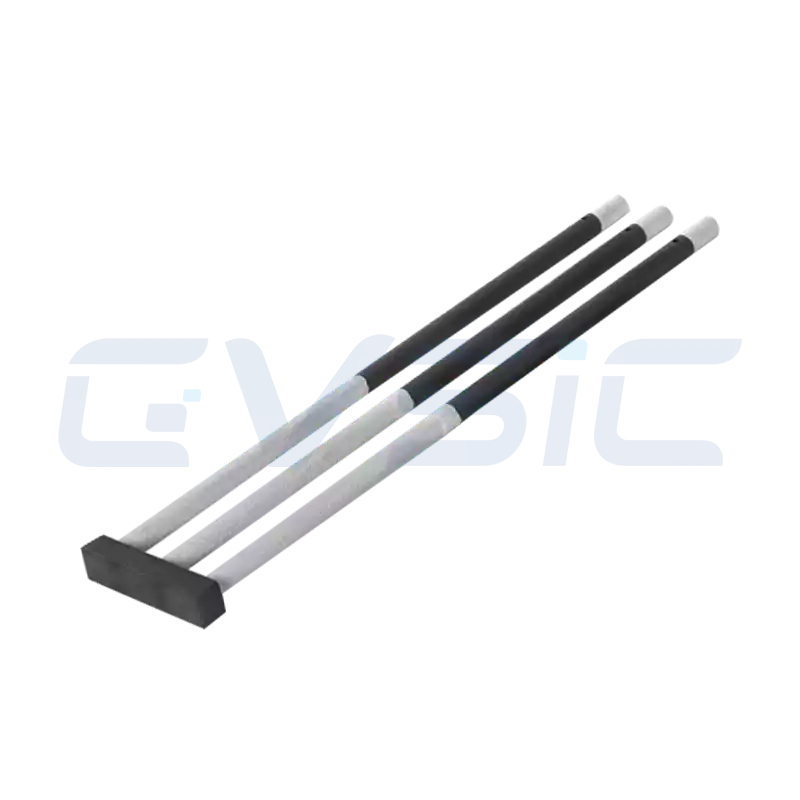

W-Type SiC Heating Elements

W-Type SiC Elements, Rods, Heater

CVSIC W-Type Silicon Carbide Heating Element, up to 1625°C (2957°F), built for float glass and high-temperature kilns, is energy-efficient and long-lasting. We offer wholesale, custom designs, and worldwide shipping—reach out for expert heating solutions!

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Shape: W-Type SIC Heating Rods

- Power Supply: 110-480V electric

- Manufacturing Process: High-quality SiC billet, high-temperature silicification recrystallization

- Diameter: 12-55mm

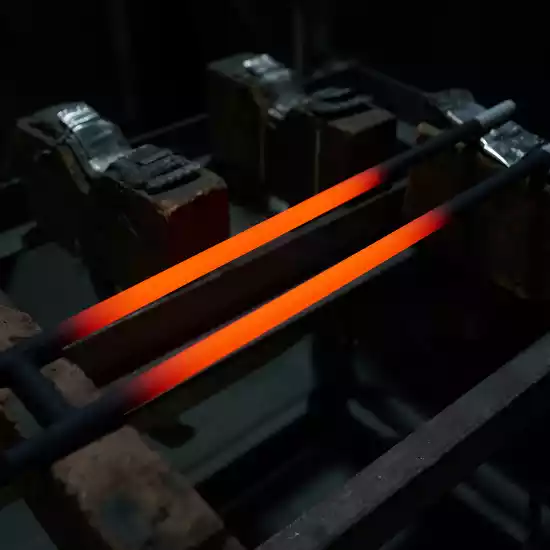

- Operating Temperature: Up to 1625℃

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

W-Type SiC Elements Description

CVSIC W-Type Silicon Carbide (SiC) Heating Element (M-Type) is crafted from high-purity, high-density SiC particles using a dry self-bonding process, shaped in a “W” configuration with three heating units designed for three-phase power applications. The hot zone surface temperature reaches up to 1600℃, with a maximum operating temperature of 1625°C (2957°F), delivering energy efficiency, a long lifespan, and excellent thermal uniformity, making it perfect for float glass production and other high-temperature industrial kilns.

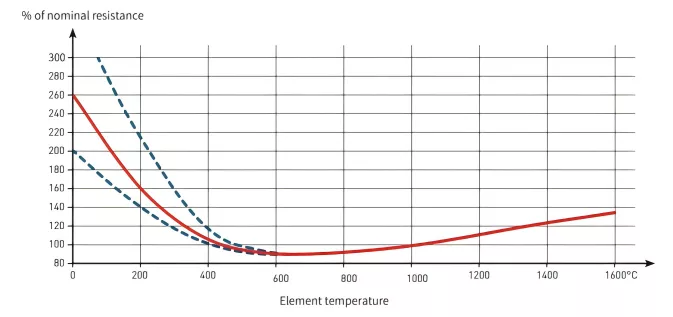

SiC Heating Elements ResistanceTemperature Performance Graphs

Ordering Information

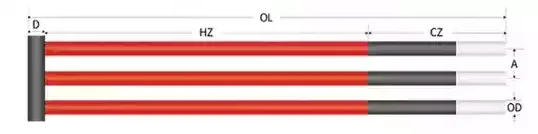

When ordering W-Type Silicon Carbide Heating Elements, please provide the following parameters:

- OD: Outer diameter (mm)

- HZ: Hot zone length (mm)

- CZ: Cold zone length (mm)

- OL: Overall length (mm)

- A: Shank spacing (mm)

- D: Connecting bridge diameter (mm)

Example: W-Type, OD=20mm, HZ=250mm, CZ=350mm, OL=625mm, A=52mm, Resistance=0.9Ω, marked as: W-Type/20/250/625/52/0.9Ω

Note: Contact us for other specifications or customization.

Installation Instructions

To ensure the performance and safety of W-Type Silicon Carbide Heating Elements, follow these installation steps:

- Inspect Element: Check for cracks or damage before installation.

- Installation Position: Cold ends form a right-angle structure with the hot zone, ideal for furnace roof or side installation in space-constrained or single-side wiring furnaces.

- Fixing Device: Use ceramic clamps or dedicated clamping devices to avoid direct contact with metal.

- Power Connection: Compatible with 110-480V three-phase power, ensure resistance matching, and use an SCR regulator for precise temperature control.

- Ventilation: Keep the installation area well-ventilated to prevent localized overheating.

- Preheating: Gradually increase power during initial use to avoid thermal shock.

- Regular Maintenance: Inspect wiring and clamping devices to ensure they are secure and free from looseness or corrosion.

Note: Professionals should perform installation; contact us for detailed guidance.

Application Fields

CVSIC W-Type Silicon Carbide Heating Elements are designed for three-phase power high-temperature kilns, widely used in:

- Float Glass Production: Manufacturing soda-lime flat glass in float glass production lines for construction, automotive, and solar glass.

- High-Temperature Industrial Kilns: Supporting ceramic sintering, metal heat treatment, and other high-uniformity heating needs.

- Special Furnace Types: Ideal for space-constrained or single-side wiring furnaces, such as tunnel kilns and shuttle kilns.

Product Advantages

- Three-Phase Power Optimization: W-Type design built for three-phase power, delivering efficient and steady heat.

- Energy-Saving and Durable: High-purity SiC material, resistant to thermal shock and oxidation, extending lifespan and cutting energy costs.

- Flexible Installation: Right-angle cold-end structure, perfect for roof or side installation in tight spaces.

- Excellent Thermal Uniformity: Three heating units enable multi-zone temperature control, improving furnace temperature consistency.

- Global Support: Backed by overseas service centers for fast response and technical guidance.

Design Recommendations

To optimize the performance of W-Type Silicon Carbide Heating Elements, follow these suggestions:

- Hot Zone Length: Match the hot zone length to the furnace chamber width to avoid insertion into the furnace wall, preventing ablation.

- Cold Zone Length: The cold zone length should match the furnace wall thickness plus an extra 50-150mm for connecting accessories.

- Furnace Aperture: The furnace aperture should be 1.4-1.6 times the cold end diameter to allow free expansion and prevent breakage.

- Spacing Design: Keep a distance of ≥3 times the outer diameter between the element and materials or furnace walls and ≥4 times the outer diameter between element centers for optimal heat distribution.

- Multi-Zone Layout: For wide or tall furnaces, arrange W-Type elements along one side with zoned temperature control to improve uniformity.

- Temperature Control System: Pair with a PID controller for precise temperature control, thereby extending the lifespan of the element.

Customization Services

CVSIC offers flexible customization for W-Type Silicon Carbide Heating Elements:

- Size Customization: Adjust outer diameter, hot/cold zone lengths, shank spacing, and connecting bridge diameter to fit your furnace design.

- Resistance Optimization: Customize resistance to match three-phase power configurations.

- Special Coatings: Provide anti-oxidation or corrosion-resistant coatings for harsh environments.

- Bulk Supply: Support large-scale wholesale with fast delivery and consistent quality.

- Technical Support: Offer engineer guidance and heat distribution analysis from selection to installation.

Contact us for customized solutions or free technical consultation!

CVSIC is dedicated to providing efficient and reliable W-type Silicon Carbide Heating Elements for global industrial clients, enhancing float glass production and other high-heat applications. Contact us for product quotes, customization services, or technical support to improve your heating efficiency!

W Type SiC Elements Accessories

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To W-Type SiC Heating Elements

DB Type SiC Heater Rods

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: DB Type

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

Straight (ED type) SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: ED/Straight/ROD/RR/GD

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

U-Type SiC Heating Elements

- Material: High-purity silicon carbide (SiC), ≥99% content

- Shape: U-Shaped SiC Heating Element

- Power Supply: 220V/380V

- Manufacturing Process: High-quality silicon carbide blank, high-temperature silicon carbide recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625℃

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

H-Type SiC Heating Elements

- Product Name: H-Type Silicon Carbide Heating Element (SiC Rod)

- Material: High-purity green hexagonal silicon carbide (SiC)

- Components: Aluminum braid, H-type stainless steel clamp (M-type clip)

- Diameter: 8-65mm (cold end/hot end)

- Temperature: Up to 1625℃ (oxidizing atmosphere)

- Voltage: 110-480V

- Appearance: Gray-green rod, smooth surface

- Packaging: Carton or export wooden crate

- Lifespan: Up to 2000 hours of continuous use

SG Type SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Shape: SS/SC/LD

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

SCR SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: SD/SCR/LS

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

Slot type (UX) SiC Heating Element

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: Slot type (UX-Type) SiC Heater

- Power Supply: 110-480V electric

- Manufacturing Process: High-quality SiC billet, high-temperature silicification recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

- Brand: CVSIC

W-Type SiC Heating Elements Relate News

How to Choose SiC Heating Elements: A Buyer’s Guide

In high-temperature industrial settings, such as ceramic firing, metal heat treatment, or semiconductor production, Silicon Carbide Heating Elements…

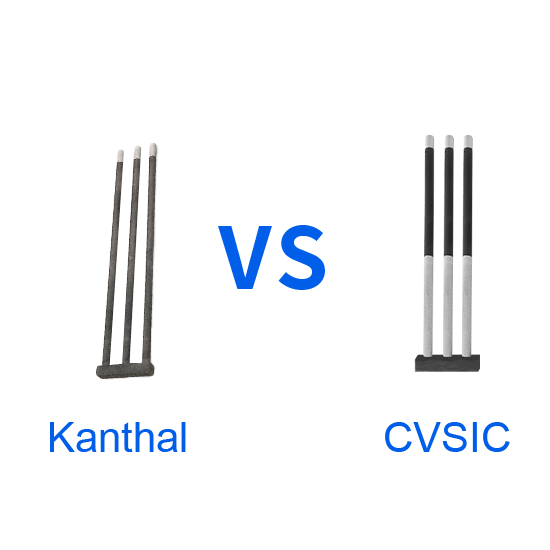

Kanthal vs CVSIC: SIC & MoSi2 Heating Element Comparison

In the realm of high-temperature industrial heating, silicon carbide and molybdenum disilicide heating elements are the primary materials…

Silicon Carbide Rod Uses, Advantages & CVSIC Heating Element Excellence

Imagine a high-temperature industrial setting: a ceramic plant’s tunnel kiln operating 24/7, a semiconductor production line requiring precise…

Silicon Carbide VS Molybdenum Disilicide Elements: Differences and Selection Guide

In high-temperature industrial settings, whether it’s kiln firing in ceramic factories, semiconductor crystal growth, or new energy battery…

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support