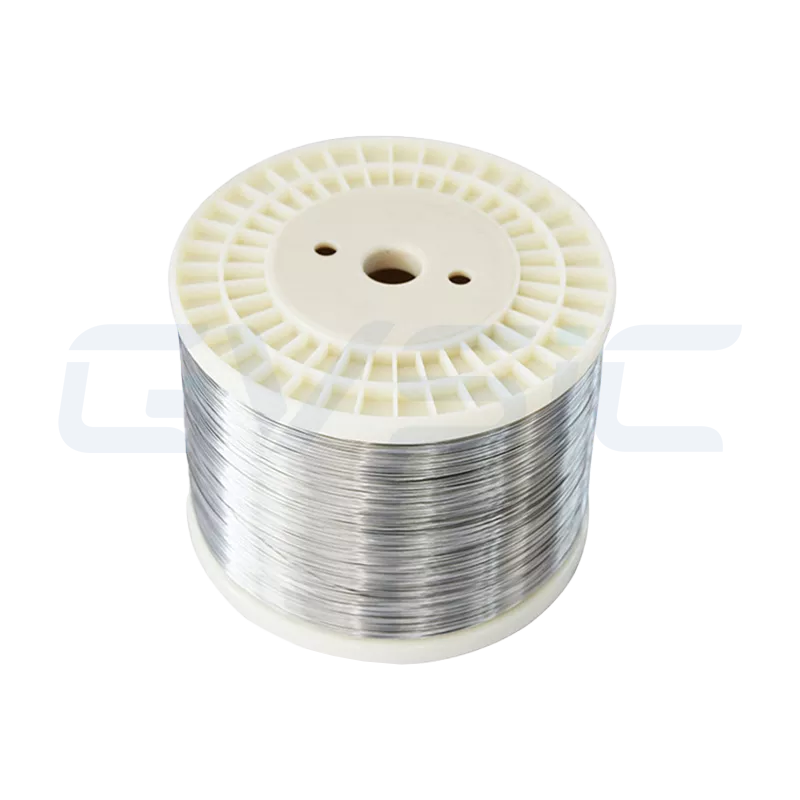

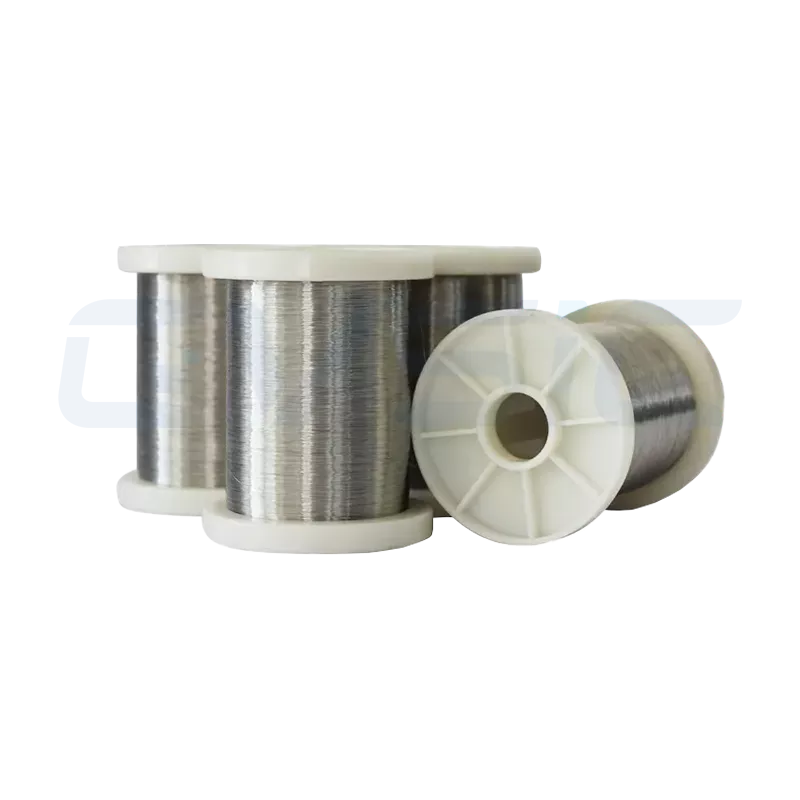

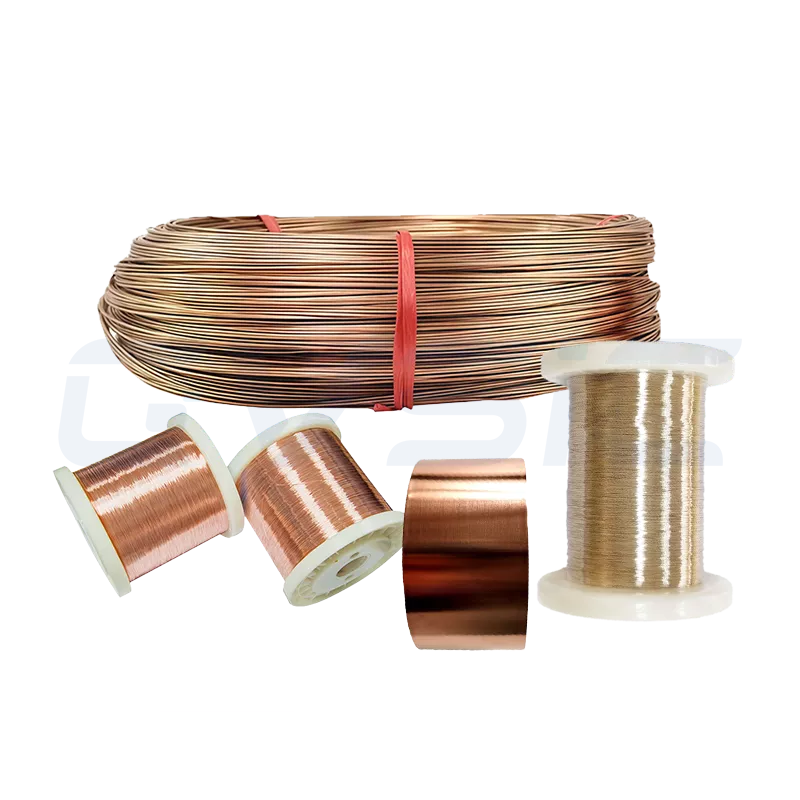

CuNi Wire

CuNi Resistance Wire is a family of resistance alloys with copper (Cu) as the base and nickel (Ni) as the main additive. Common grades include CuNi2, CuNi6, CuNi10, CuNi23, CuNi44 (Constantan).

In electric heating and resistance setups, not every job chases higher temps. CuNi resistance wire’s real strength is:

- Crazy low temperature coefficient of resistance

- Controllable drift over time and heat cycles

- No sudden jumps from oxidation in mid-low temps

So it’s huge in precision resistors, temp compensation circuits, low-temp heating, and signal resistors—not main heaters in industrial furnaces.

CuNi Resistance Wire Manufacturer and Supplier In China

In the resistance wire world, CuNi’s spot is crystal clear: NiCu wire isn’t built for “high-temp heating.”

The one big reason it’s picked: In a set temp range, resistance barely budges with heat changes—and you can predict it long-term.

If your setup cares more about signal steadiness, repeatable power, or measurement accuracy than max temp, NiCu’s the smart call.

Engineering Logic and Features of CuNi Resistance Wire

NiCu (copper-nickel) alloys aren’t chasing extreme heat—they solve a real-world issue: Mid-low to mid-high temps, long energized runs—keep resistance steady, temps even, life predictable.

Engineering Breakdown

- Copper base → Great heat spread, even temps

- Bump nickel gradually → Resistivity up, stability better

- Single-phase solid solution → No funky phase shifts, safe hot-cold cycles

- Low magnetism → Plays nice with controls, measurements, electrics

Standouts

- Resistance changes tiny with temp

- No fancy temp compensation needed

- Super slow surface oxidation

- Oxide layer barely affects cross-section

- Easy to draw thin

- Simple small coil winding

- Warns with stretch before snap—not brittle break

Buy High-Quality CuNi from China

Quick Navigation

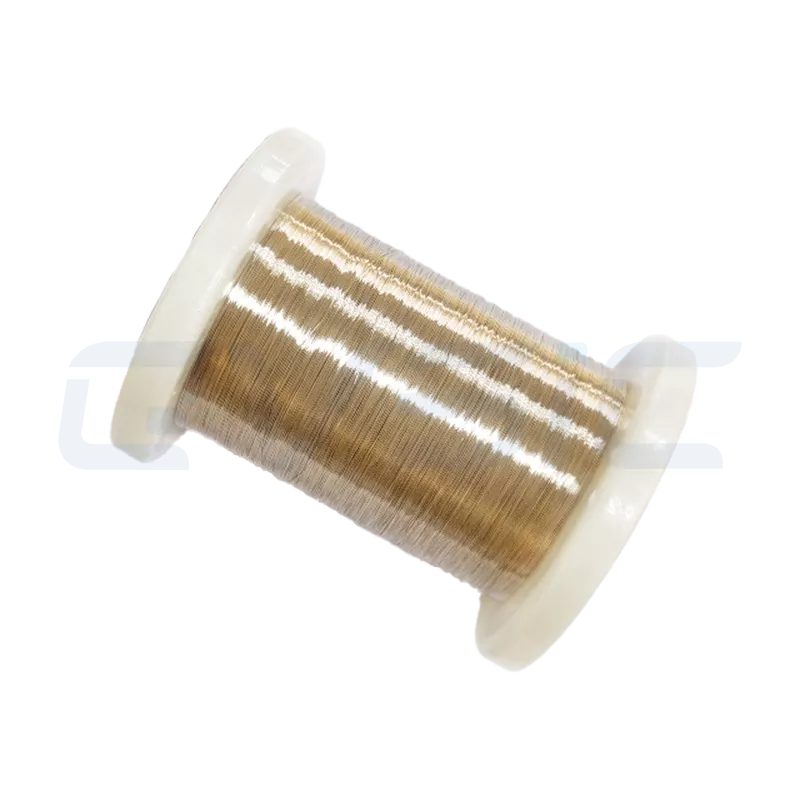

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

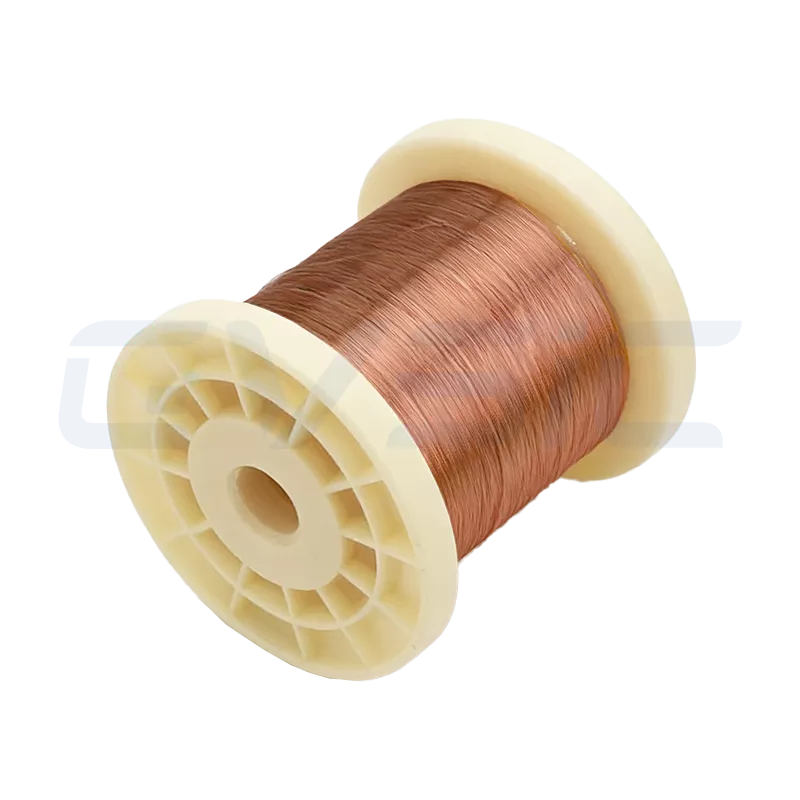

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

NiCu Wire Custom Services

In NiCu jobs, results hinge less on “CuNi44 or not” and more on:

- Spot-on composition

- Tight diameter tolerance

- Consistent resistance

- Batch steadiness

- Annealing/drawing control

We got:

- Custom diameters/resistance

- OEM coiling/cutting

- Batch consistency

- Reports included

Serving instrument makers, control builders, industrial electronics.

Why Choose CVSIC?

Solve your problems with cvsic’s powerful capabilities

Production Capacity

Quality Control

Quick Support

Global Partnership

CuNi Resistance Wire Applications

NiCu wire apps aren’t “hotter is better”—super focused:

- Precision wound resistors

- Temp compensation resistors

- Instrument/sensor internals

- Low-temp heating plates, defrost stuff

- Stable loads in lab gear

If you’re aiming for 1200°C heat, fast ramps, or high loads, NiCu ain’t in the running.

When Not to Pick CuNi Resistance Wire

- Long-term over 700°C Copper-base stability drops, resistance gets unpredictable.

- High surface power density needed NiCu can’t handle heavy W/cm²—life in hours, not years.

- Oxidizing, sulfidizing, corrosive air NiCu not made for harsh stuff—clear life limits.

CuNi vs NiCr vs FeCrAl

| Feature | NiCu Wire | NiCr Wire | FeCrAl Wire |

|---|---|---|---|

| Reasonable Temp Range | ≤600°C (some a bit higher) | 800–1100°C | 1000–1300°C |

| Temp Coefficient | Crazy low (near constant) | Medium | Higher |

| Relies on Oxide Layer | No (low temp not key) | Yes (Cr₂O₃) | Yes (Al₂O₃) |

| On-Off Impact on Resistance | Tiny | Medium | Noticeable |

| Cost | Medium | Higher (nickel) | Lower |

| Typical Uses | Precision/compensation | Mid-high heating | High-temp industrial |

| Common Misuse | Mid-high heating | Low-temp measurement | Frequent on-off |

Core Call:

Engineering FAQs

CuNi for high-temp heating?

Nope—CuNi wins on resistance stability, not heat.

CuNi and Constantan link?

Constantan is usually CuNi44—one in the CuNi lineup.

High-precision resistance custom?

Yeah—tailor value/tolerance to your job.

Lead times?

Stock commons fast, customs per tech confirm.

CuNi resistance wire stands out for mid-low temp precision and stability—pick it when resistance steadiness trumps max heat.

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support