FeCrAl Alloy

FeCrAl resistance wire is a heating alloy made mainly from iron (Fe), chromium (Cr), and aluminum (Al). It reliably converts electrical energy into heat through resistance and is designed for long-term use in high-temperature air environments.

- √ Continuous operating temp: 1000–1400°C

- √ Gets long-term oxidation protection from an Al₂O₃ layer

- √ Iron-based, so it’s way more affordable than NiCr

- × Not good for sulfur-rich, strongly reducing, or high-hydrogen environments

If your setup runs hot for extended periods in regular air, FeCrAl is usually the better choice.

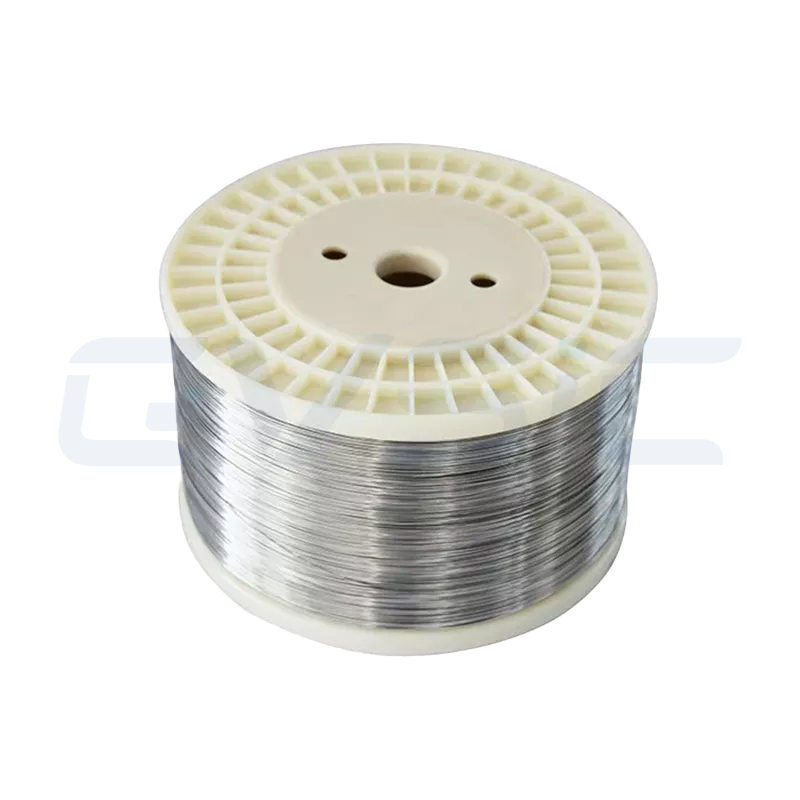

FeCrAl Alloy Wire Manufacturer and Supplier In China

FeCrAl resistance wire builds a tight, stable aluminum oxide layer (Al₂O₃) at high heat, keeping oxidation super slow over long runs. That’s why it’s awesome for non-stop, long-cycle, high-temp setups. Unlike the Cr₂O₃ layer from NiCr, Al₂O₃ is tougher and denser—the real reason FeCrAl lasts way longer in air above 1000°C.

With killer high-temp tolerance, top oxidation resistance, and long life, FeCrAl wire is all over industrial kilns, heat treatment gear, lab heaters, and always-on industrial heating systems.

For industrial folks who put stability, life, and manageable upkeep first, FeCrAl is a proven, dependable pick.

CVSIC FeCrAl Resistance Wire Standouts

FeCrAl alloys are made for long energized runs at high heat without failing, oxidizing fast, or unpredictable life.

It’s not about quick stuff—it’s built for steady long-haul service at crazy temps.

Engineering Breakdown

- Iron base → Tough structure, keeps costs down—ideal for huge industrial heating

- High chrome → Basic oxidation protection

- Aluminum’s the star → Builds that dense Al₂O₃ layer at heat, the real life extender

- Self-healing layer → Fixes local damage, reforms protection

- High resistivity → Shorter wire for same power, tighter designs

- No fancy metals → Big cost win in high-power hot furnaces

Standouts

- Steady runs in 1200–1400°C range long-term

- Crazy low oxidation at heat—outlasts NiCr by miles

- Stable layer doesn’t mess with resistance—predictable performance

- Perfect for always-on jobs (industrial furnaces, heat treat ovens)

- Holds strength hot—no easy sag

- Not for lots of on-off—better for “flip on and forget” systems

- Custom sizes, resistance, power—whatever you need

Buy High-Quality FeCrAl from China

Quick Navigation

0Cr27Al7Mo2 Wire Kanthal APM Alternative

- Model: CV-0Cr27Al7Mo2

- Alloy Grade: Fe–Cr–Al–Mo high-temp resistance alloy

- Main Composition: Fe: Bal., Cr ≈27%, Al ≈7%, Mo (trace)

- Max Temp: ≤ 1400°C

- Resistivity (20°C): 1.50 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr21Al6Nb Resistance Wire Kanthal A1 Alternative

- Model: CV-0Cr21Al6Nb

- Alloy Grade: Fe–Cr–Al–Nb resistance alloy

- Main Composition: Fe: Bal., Cr ≈21%, Al ≈6%, Nb (trace)

- Max Temp: ≤ 1350°C

- Resistivity (20°C): 1.45 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr25Al5 Resistance Wire

- Model: CV-0Cr25Al5

- Alloy Grade: 0Cr25Al5 (FeCrAl 255)

- Main Composition: Fe: Bal.; Cr: 24–26; Al: 4.8–6.0; Mo: ≤0.5

- Max Temp: 1300°C

- Resistivity (20°C): 1.42 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr21Al6 Resistance Wire

- Model: CV-0Cr21Al6

- Alloy Grade: 0Cr21Al6 (FeCrAl 216)

- Main Composition: Fe: Bal.; Cr: 20–22; Al: 5.0–7.0; Mo: ≤0.5

- Max Temp: 1250–1300°C

- Resistivity (20°C): 1.35 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr23Al5 Alloy Wire

- Model: CV-0Cr23Al5

- Alloy Grade: 0Cr23Al5 (FeCrAl 235)

- Main Composition: Fe: Bal.; Cr: 22–24; Al: 4.5–6.0; Mo: ≤0.5

- Max Temp: 1250°C

- Resistivity (20°C): 1.40 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Tensile Strength: Tensile Strength ≥650 MPa

1cr20al3 Wire

- Model: CV-1Cr20Al3

- Alloy Grade: 1Cr20Al3 (FeCrAl low-aluminum resistance alloy)

- Main Composition: Fe: Bal., Cr 19–21%, Al 2.5–3.5%

- Max Temp: 1000–1100°C

- Resistivity (20°C): 1.25–1.35 μΩ·m

- Density: 7.2 g/cm³

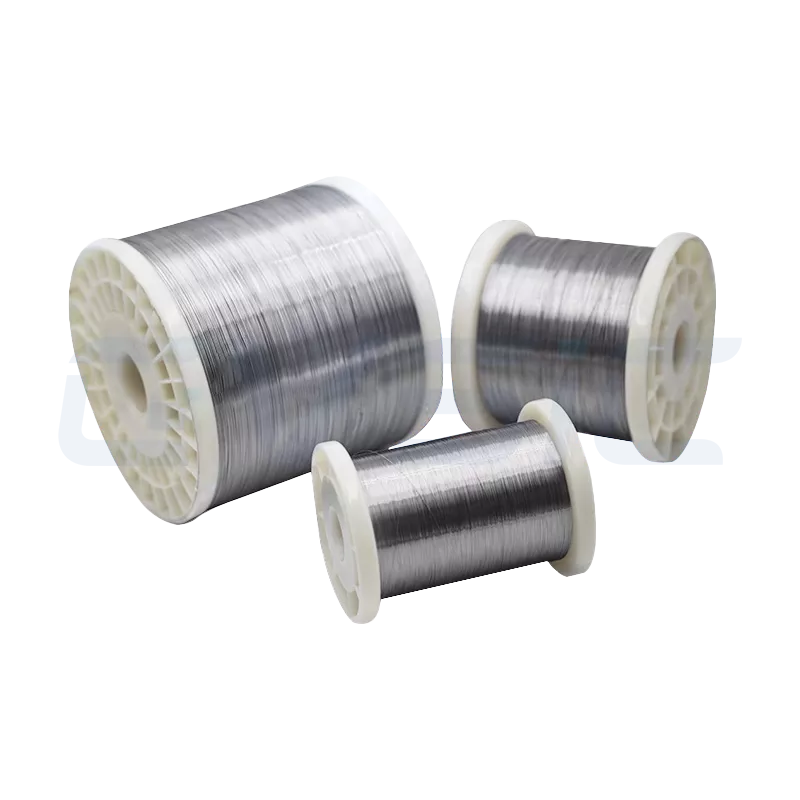

- Forms Available: Wire, flat strip, ribbon, coiled, seamless spools

- Best Atmosphere: Air / Mildly oxidizing

1Cr13Al4 Alloy Wire

- Model: CV-0Cr21Al6

- Alloy Grade: 0Cr21Al6 (FeCrAl 216)

- Main Composition: Fe: Bal.; Cr: 20–22; Al: 5.0–7.0; Mo: ≤0.5

- Max Temp: 950°C

- Resistivity (20°C): 1.20-1.30 μΩ·m

- Density: 7.2 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

CVSIC's FeCrAl Resistance Wire Wholesale and Customization

- Straight or coiled wire

- Custom diameters and lengths

- Tailored to your resistance or power needs

- Fits with ceramic supports and insulators

- Precise control over alloy composition

- Made to your drawings or specs

- Small-batch prototypes + full production runs

- Reliable delivery for ongoing projects

- Supplying kiln builders, system integrators, and lab equipment makers

With years of experience, CVSIC delivers smart, effective heating solutions.

Why Choose CVSIC?

Solve your problems with cvsic’s powerful capabilities

Production Capacity

Quality Control

Quick Support

Global Partnership

When to Go with FeCrAl

If your setup matches these, FeCrAl is typically the best bet:

- Atmosphere: Air or oxygen-rich hot air

- Continuous temp: 900°C or higher

- Mode: Long, non-stop heating

- Goals: Cut costs and stretch replacement intervals

Common industries:

- Industrial heat treatment furnaces

- Ceramic sintering kilns

- Glass annealing and forming gear

- High-temp heating modules

When NOT to Pick FeCrAl

Choosing an unsuitable material is not due to product deficiency, but rather to misapplication.

| Material | Temp Range | Suitable Atmospheres | Cost | Key Limitations / Notes |

|---|---|---|---|---|

| FeCrAl | 1000–1400°C | Air or oxygen-rich | Low | Weak in sulfur-containing or reducing atmospheres |

| NiCr | 800–1200°C | Most corrosive environments | Moderate to high | Shorter lifespan at very high temps |

| MoSi2 | 1200–1800°C | Air | High | Very brittle with high cost |

| SiC | Above 1400°C | Varies by type/structure | High | Very sensitive to thermal shock |

In those cases, NiCr, MoSi2, or SiC are safer alternatives.

Applications for FeCrAl Resistance Wire

- Industrial kilns: Box, bogie, roller hearth—handles constant high heat.

- Heat treatment systems: Steady heat for annealing, normalizing, and tempering.

- Lab heaters: Great for test furnaces needing precise, stable temps.

- Automated line heating: Easy to integrate into modular units.

- Coating and drying setups

FeCrAl vs. Other Options

| FeCrAl | 1000–1400°C | Air / oxygen | Low | Vulnerable to sulfur/reducing |

|---|---|---|---|---|

| NiCr | 800–1200°C | Most corrosive | Medium-High | Shorter life at extreme temps |

| MoSi2 | 1200–1800°C | Air | High | Brittle and pricey |

| SiC | >1400°C | Varies by design | High | Sensitive to thermal shock |

Quick Decision Guide

- High temp + air → FeCrAl

- Corrosive or reducing → NiCr

- Ultra-high temp → MoSi2 / SiC

FAQ

What’s the typical lifespan for FeCrAl wire?

With proper power loading and good airflow, it can run reliably for years.

Max operating temperature?

Up to 1400°C, depending on the exact alloy and conditions.

Do you offer OEM customization?

Yes, customization is available for diameter, length, resistance, power, and even packaging.

How long until delivery?

Stock items ship fast; custom orders are scheduled based on the details provided.

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support