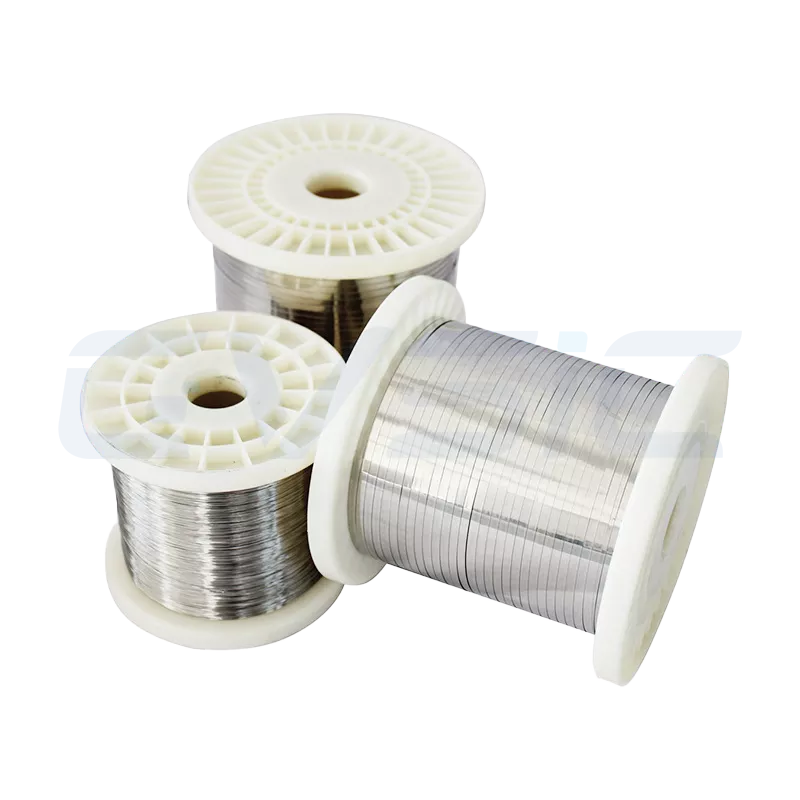

NiCr Heating Wire

NiCr resistance wire is a heating alloy made mainly from nickel (Ni) and chromium (Cr). It turns electricity into steady, controllable heat thanks to its reliable resistance properties.

In the 800–1200°C range for industrial heating, NiCr is often chosen—not because it’s the absolute toughest against heat, but because it strikes a solid practical balance for temperature control, on/off cycling, and a predictable lifespan.

For systems that switch on and off a bunch, need power tweaks, or have tight space, NiCr is often easier to work with than super-high-temp options and plays well with controllers long-term.

NiCr Alloy Wire Manufacturer and Supplier In China

NiCr resistance wire is known for rock-solid resistance stability, consistent heat response, and tough mechanical strength. It’s everywhere in industrial and home heating setups that need spot-on temp control and reliable on-off performance.

How NiCr wire heats up boils down to resistivity + oxidation setup + thermal expansion.

When powered, the nickel-chrome alloy cranks out Joule heat from its resistance.

In hot air, the surface builds a tight Cr₂O₃-based oxide layer. So:

- Same power design? NiCr heat output stays nice and linear

- No constant recalibrating temp controls

- System life is way easier to guess

For setups needing tight temp stability, repeatability, and predictability, NiCr is usually the safer bet.

NiCr Alloy Standouts

NiCr resistance wire is built for stability, predictability, and long-haul reliability—not pushing temp extremes.

Engineering Breakdown

- Nickel base → Super ductile, tough against heat fatigue

- Chrome for oxidation fight → Builds stable Cr₂O₃ layer in mid-high heat

- Single austenitic structure → Stays steady through hot-cold cycles, no easy brittleness

- Moderate linear resistivity → Easy power math and temp matching

- Solid mechanical toughness → Great for tricky coiling/small heaters

- Non-magnetic → Plays nice with sensors/controls

Standouts

- Max temps usually 1100–1200°C

- Quick heat-up, perfect for lots of on-off

- Smooth resistance-temp curve—temp systems tune easy

- No fancy power tweaks needed

- Easy to make thin/tight spirals

- Holds up better in vibes/thermal shocks

- Long hot life shorter than FeCrAl, but way better control

Buy High-Quality NiCr from China

Quick Navigation

Cr20Ni80 Heating Wire

- Model: CV-Cr20Ni80

- Alloy Grade: Ni80Cr20

- Main Composition: Ni: Bal., Cr: 20–23, Fe: ≤1%

- Max Temp: 1200°C

- Resistivity (20°C): 1.09 μΩ·m

- Density: 8.4 g/cm³

- Forms Available: Diameters: 0.018–10mm; Strips: 0.02–2mm; Custom tolerances

- Common Uses: High-temp furnaces, lab gear, ceramic sintering, cutting wires, appliance heaters

Cr30Ni70 Heating Wire

- Model: CV-Cr30Ni70

- Alloy Grade: NiCr70/30

- Main Composition: Ni: Bal. (about 70%), Cr: 28–31%, Fe: ≤1.0%

- Max Temp: 1200°C

- Resistivity (20°C): 1.18 μΩ·m

- Density: 8.1 g/cm³

- Forms Available: Diameters: 0.02–10mm (round) Strips: 0.02–2mm Custom flat wire, rods, coils

- Common Uses: Industrial furnace wires – High-temp elements – Ceramic heaters – High-temp ovens/tunnel kilns – Mold heating, lab furnaces

Cr20Ni35 Heating Wire

- Model: CV-Cr20Ni35

- Alloy Grade: Nichrome 35/20

- Main Composition:Ni: Cr: ≈20%, Ni: ≈35%, Fe: Bal.

- Max Temp: 1100–1150°C

- Resistivity (20°C): 1.02 μΩ·m

- Density: 8.0 g/cm³

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Mid-high temp industrial furnaces, ovens, heating tubes, durable elements

Cr20Ni30 Alloy Heatin Wire

- Model: CV-Cr20Ni30

- Alloy Grade: Nichrome 70/30, Ni70Cr30

- Main Composition:Ni: Cr: 18–21%, Ni: 30–34%, Fe: Bal.

- Max Temp: 1100°C

- Resistivity (20°C): 1.04 μΩ·m

- Density: 7.9 g/cm³

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Heaters, electric tubes, hair dryer wires, damping/cutting wires (foam/plastic)

Cr15Ni60 Alloy Wire

- Model: CV-Cr15Ni60

- Alloy Grade: Nichrome 60/15

- Main Composition:Ni: 55–61%, Cr: 15–18%, Fe: Bal.

- Max Temp: 1100°C

- Resistivity (20°C): 1.12 μΩ·m

- Density: 8.2 g/cm³

- Forms Available: Wire, strip, flat; 0.03–8mm diameters; custom coiling

- Common Uses: Industrial furnaces, oven elements, heating tubes, mold heaters, durable wires

What CVSIC Offers for NiCr

- Straight or coiled wire

- Spiral coils

- Flat ribbons

- Custom diameter, resistivity, and power

OEM/ODM/Wholesale and Custom Engineering

For NiCr projects, we deliver:

- Tight alloy composition control

- Exact resistance and power matching

- Prototypes to full runs

- Fit for ceramic mounts and tube designs.

- Steady supply for equipment builders and integrators

Why Choose CVSIC?

Solve your problems with cvsic’s powerful capabilities

Production Capacity

Quality Control

Quick Support

Global Partnership

NiCr resistance wire shines in

- Heat treatment gear: Mid-temp annealing/preheat with steady curves.

- Home/commercial appliances: Ovens, water heaters, heating modules.

- Lab heaters: Precise-set plates/furnaces.

- Auto line heating bits: Matches temp controls, handles on-off fine.

- Coating/drying setups

When does NiCr fit best?

NiCr isn’t the temp king, but it’s often the lowest-risk pick here.

| Need | Why NiCr Rocks It |

|---|---|

| Lots of start-stop | Less expansion than FeCrAl, better fatigue fight |

| Spot-on temp control | Low temp coefficient, linear output |

| Tight builds | High resistivity, controllable heat per length |

| Air/mild oxidizing | Stable Cr₂O₃ layer |

When NiCr ain’t the move

In B2B gigs, NiCr “fails” usually from ignoring limits, not the material.

NiCr vs. Common Alternatives

In electric heating materials, NiCr wire:

- Beats FeCrAl for frequent cycling and precise control

- Outlasts and stabilizes better than stainless steel wires.

- Offers more flex and integration than quartz tubes

| Temp control precision | High | Medium | Medium | Medium |

|---|---|---|---|---|

| On/off adaptability | Excellent | Okay | Poor | Okay |

| Toughness | High | Brittle | Brittle | Fragile |

| Customization ease | High | Low | Low | Medium |

FAQ

Is NiCr good for long-term high-temp runs?

Yeah, for mid-to-high temps, but for extreme constant heat, go with FeCrAl.

What’s NiCr best at?

Frequent cycling, tight temperature control, and handling thermal shocks.

OEM customization?

Yep—diameter, resistance, length, coiling styles.

Delivery times?

Stock stuff ships fast; customs on project timeline.

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support