Comprehensive Guide to Tube Furnaces: Types, Principles, and Applications

What is a Tube Furnace? Your Gateway to High-Temperature Applications Tube furnaces are essential high-temperature heating systems widely…

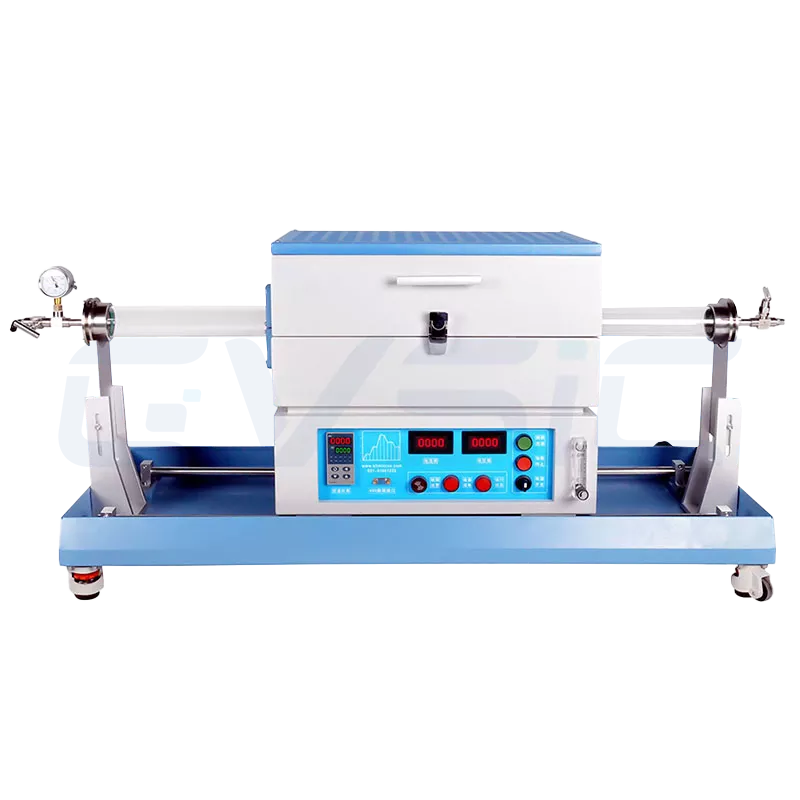

CVSIC’s tubular electric furnace lineup includes vacuum tubular furnaces, rotary kiln tubular furnaces, vertical tubular furnaces, rapid-cooling tubular furnaces, and activation tubular furnaces. Engineered for high-temperature industrial and laboratory applications, these furnaces deliver outstanding precision, durability, and versatility.

As a leading tube furnace manufacturer in China, we offer OEM branding, wholesale options, and fully customized solutions to address your unique needs.

Source premium tubular furnaces directly from a leading China-based factory, securing high-quality products at competitive prices to fulfill your specific high-temperature industrial demands!

We offer global clients tubular furnace sales, wholesale, custom design, installation, and ongoing support, catering to your operational needs and supporting B2B partnerships.

We deliver comprehensive B2B services to meet your tubular furnace requirements:

Solve your problems with cvsic’s powerful capabilities

Our tubular furnaces support a broad spectrum of industries, including:

We offer a range of finished tubular furnaces with tube diameters ranging from 50 to 300 mm, supporting temperatures of up to 1800°C using SiC or MoSi₂ elements. Contact us for a detailed catalog and to inquire about stock availability.

Yes, our OEM branding services enable you to customize our high-quality furnaces to match your brand, integrating them seamlessly into your product line.

Finished units typically ship within 2 to 4 weeks, depending on location and order size, with priority on efficient global logistics.

Absolutely, we specialize in custom designs, tailoring furnaces to your specific tube diameter, heating zones, and atmosphere control needs. Delivery for custom orders typically takes 8 to 12 weeks.

Our furnaces utilize advanced insulation materials, including ceramic fiber and alumina ceramics, in conjunction with optimized heating systems, to minimize energy consumption, lower costs, and maintain high performance.

We offer 24/7 technical support, spare parts, and maintenance services to ensure long-term reliability, backed by dedicated account managers for prompt assistance.

What is a Tube Furnace? Your Gateway to High-Temperature Applications Tube furnaces are essential high-temperature heating systems widely…

Rotary vs. Fixed Tube Furnaces: Choosing the Ideal Solution for Your Process When processing powder materials, issues like…

Vertical vs. Horizontal Tube Furnaces: Choosing the Right Equipment for Your Needs When selecting tube furnaces for materials…

Vacuum vs. Atmosphere Tube Furnaces: Selecting the Optimal Equipment for Your Experiments Sample oxidation or contamination in high-temperature…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support