DB Type SiC Heater Rods

DB Type SiC Heating Elements, Rods, Heater

CVSIC DB Type (Dumbbell) Silicon Carbide Heating Element, up to 1625°C (2957°F), high-temperature and corrosion-resistant, great for ceramics, electronics, lithium batteries, and high-temperature kilns. Offering global wholesale, customization, and OEM/ODM services. Contact us for free samples!

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: DB Type

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

DB Type SiC Rods Description

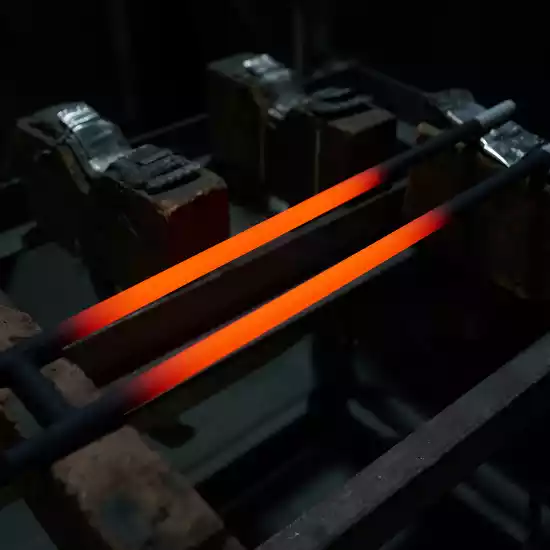

CVSIC DB Type Silicon Carbide Heating Elements (Dumbbell/SC/Large-Head Rod) are made from high-density, high-purity silicon carbide using a special process that rigidly connects a high-resistance hot zone with two thickened low-resistance cold zones, ensuring excellent mechanical and electrical performance. With a hot zone density of up to 2.8 g/cm³ and a maximum operating temperature of 1625°C (2957°F), they offer high-temperature resistance, low aging, rapid heating, and corrosion resistance. Great for small box furnaces, laboratory furnaces, tunnel furnaces, and industries such as ceramics, electronics, and lithium battery production, these elements provide an affordable and high-performance heating solution.

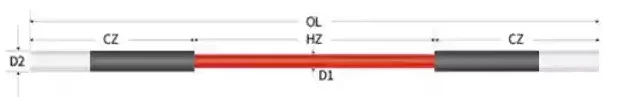

DB type Rods Ordering Information

When ordering DB Type Silicon Carbide Heating Elements, please provide the following parameters:

- OD: Outer Diameter (mm)

- HZ: Hot Zone Length (mm)

- CZ: Cold Zone Length (mm)

- OL: Overall Length (mm)

- d: Hot Zone Diameter (mm)

- Resistance: Ω

- Example: DB Type, d=8mm, D=14mm, HZ=150mm, CZ=100mm, OL=350mm, Resistance=1.5Ω, denoted as: dia8/14x150x350mmx1.5Ω

Note: Contact us for other specifications or customization.

DB Type SiC Elements Connection Method

- Contact Surface Design: The cold end is coated with an aluminum strip for low-resistance contact, ensuring efficient conductivity.

- Electrical Connection: Secured with a flat aluminum braid and spring clips, suitable for single- or double-end connections, ensuring a stable installation.

- Note: Select the appropriate voltage (110-480V) and connection method based on furnace power and temperature requirements. Use an SCR voltage regulator (a device for precise temperature control) to extend lifespan.

DB Type SiC Heater Application Fields

CVSIC DB Type Silicon Carbide Heating Elements are widely used in:

- Small Box Furnaces: Supports laboratory and small-scale industrial heating needs.

- Laboratory Furnaces: For material testing and high-temperature experiments.

- Tunnel/Muffle Furnaces: Meets ceramic sintering and powder metallurgy process requirements.

- Electronics Industry: Used in semiconductor manufacturing and electronic component encapsulation.

- Lithium Battery Materials: Supports high-temperature processing of battery anode and cathode materials.

- Rare Earth Phosphors and Precision Casting: Provides high-temperature stability and uniform heating.

CVSIC DB Type SiC Rods Advantages

- High-Temperature Resistance: Operates up to 1625°C (2957°F), ideal for demanding high-temperature environments.

- Low Aging: High-density silicon carbide (2.8 g/cm³) is oxidation-resistant, slows down aging, and ensures a long lifespan.

- Quick and Uniform Heating: Thickened cold zones and high-resistance hot zone design enable rapid and uniform heating.

- Corrosion Resistance: Self-bonded silicon carbide material resists acids and alkalis, suitable for harsh conditions.

- Flexible Installation: Self-supporting design for easy setup in vertical or horizontal installation, allows replacement at operating temperatures.

- Global Service: ISO-certified factory, 360-ton annual capacity, offers free samples, and 7-30 day delivery.

DB Type SiC Rods Installation Method

To ensure the performance and safety of DB Type Silicon Carbide Heating Elements, follow these steps:

- Inspect Element: Before installation, ensure the element is free of cracks or damage.

- Installation Type: Supports both vertical and horizontal installation; the self-supporting design requires no additional support.

- Fixing Device: Use ceramic chucks or dedicated clamping devices to avoid direct metal contact.

- Power Connection: Connect to a 110-480V power supply with flat aluminum braid and spring clips for proper resistance matching.

- Hot Furnace Replacement: Replace at operating temperatures by turning off the power, loosening the spring clips and aluminum braid, and smoothly inserting the new element to avoid thermal shock or melting of the aluminum coating.

- Ventilation: Maintain good ventilation in the installation area to prevent localized overheating.

- Preheating: Gradually increase power during first use to avoid thermal shock.

- Regular Maintenance: Check aluminum coating connections and clamps for looseness or corrosion.

Note: Professionals should perform the installation. Contact us for detailed guidance.

DB Type SiC Rods Design Recommendations

To optimize the performance of DB Type Silicon Carbide Heating Elements, follow these suggestions:

- Hot Zone Length: Match the hot zone length to the furnace width to avoid insertion into the furnace wall, preventing ablation.

- Cold Zone Length: Cold zone length should equal furnace wall thickness plus 50-150mm extension for accessory connection.

- Furnace Aperture: The furnace aperture should be 1.4-1.6 times the cold zone diameter to allow free expansion and prevent cracking.

- Spacing Design: Maintain ≥3 times the outer diameter between the element and material/furnace wall and ≥4 times the outer diameter for center-to-center spacing to optimize heat distribution.

- Temperature Control System: Use a PID controller for precise temperature control to extend the element’s lifespan.

- Hot Furnace Replacement: Control insertion speed during replacement to avoid aluminum coating melting or thermal shock.

CVSIC Customization Services

CVSIC offers flexible customization for DB Type Silicon Carbide Heating Elements:

- Size Customization: Adjust hot/cold zone diameter and length to fit your furnace design.

- Resistance Optimization: Customize resistance to match 110-480V power configurations.

- Special Cold End Design: Optimize thickened cold zone structure for enhanced conductivity and durability.

- Special Coatings: Offer oxidation-resistant or corrosion-resistant coatings for improved performance in harsh environments.

- OEM/ODM Services: Support bulk wholesale, free samples, and 7-30 day delivery.

- Technical Support: Offer expert guidance and thermal field simulation for selection and installation.

CVSIC is dedicated to delivering top-quality DB Type Silicon Carbide Heating Elements for industries worldwide, optimizing ceramics, electronics, lithium batteries, and high-temperature processes. Contact us for product quotes, customization services, or free samples to boost your heating efficiency!

DB Type SiC Elements Accessories

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To DB Type SiC Heater Rods

Straight (ED type) SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: ED/Straight/ROD/RR/GD

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

U-Type SiC Heating Elements

- Material: High-purity silicon carbide (SiC), ≥99% content

- Shape: U-Shaped SiC Heating Element

- Power Supply: 220V/380V

- Manufacturing Process: High-quality silicon carbide blank, high-temperature silicon carbide recrystallization

- Diameter: 8-65mm

- Operating Temperature: Up to 1625℃

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

H-Type SiC Heating Elements

- Product Name: H-Type Silicon Carbide Heating Element (SiC Rod)

- Material: High-purity green hexagonal silicon carbide (SiC)

- Components: Aluminum braid, H-type stainless steel clamp (M-type clip)

- Diameter: 8-65mm (cold end/hot end)

- Temperature: Up to 1625℃ (oxidizing atmosphere)

- Voltage: 110-480V

- Appearance: Gray-green rod, smooth surface

- Packaging: Carton or export wooden crate

- Lifespan: Up to 2000 hours of continuous use

W-Type SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Shape: W-Type SIC Heating Rods

- Power Supply: 110-480V electric

- Manufacturing Process: High-quality SiC billet, high-temperature silicification recrystallization

- Diameter: 12-55mm

- Operating Temperature: Up to 1625℃

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

SG Type SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Shape: SS/SC/LD

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

SCR SiC Heating Elements

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: SD/SCR/LS

- Power Supply: 110-480V

- Production Process: High-quality SiC blank, high-temperature silicon recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam padding, outer export wooden crate

- Applications: Industrial heaters, furnace heaters

- After-Sales Service: Global service center support

Slot type (UX) SiC Heating Element

- Material: High-purity Silicon Carbide (SiC), ≥99% content

- Type: Slot type (UX-Type) SiC Heater

- Power Supply: 110-480V electric

- Manufacturing Process: High-quality SiC billet, high-temperature silicification recrystallization

- Diameter: 12-90mm

- Operating Temperature: Up to 1625°C (2957°F)

- Packaging: Inner carton with foam filling, outer export wooden crate

- After-Sales Service: Global service center support

- Brand: CVSIC

DB Type SiC Heater Rods Relate News

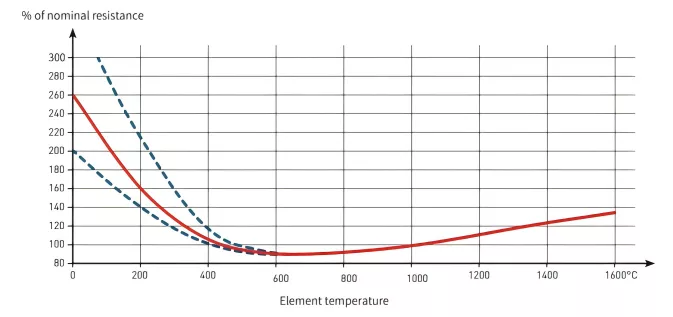

Kanthal vs CVSIC: SIC & MoSi2 Heating Element Comparison

In the realm of high-temperature industrial heating, silicon carbide and molybdenum disilicide heating elements are the primary materials…

How to Choose SiC Heating Elements: A Buyer’s Guide

In high-temperature industrial settings, such as ceramic firing, metal heat treatment, or semiconductor production, Silicon Carbide Heating Elements…

Silicon Carbide Rod Uses, Advantages & CVSIC Heating Element Excellence

Imagine a high-temperature industrial setting: a ceramic plant’s tunnel kiln operating 24/7, a semiconductor production line requiring precise…

Silicon Carbide VS Molybdenum Disilicide Elements: Differences and Selection Guide

In high-temperature industrial settings, whether it’s kiln firing in ceramic factories, semiconductor crystal growth, or new energy battery…

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support