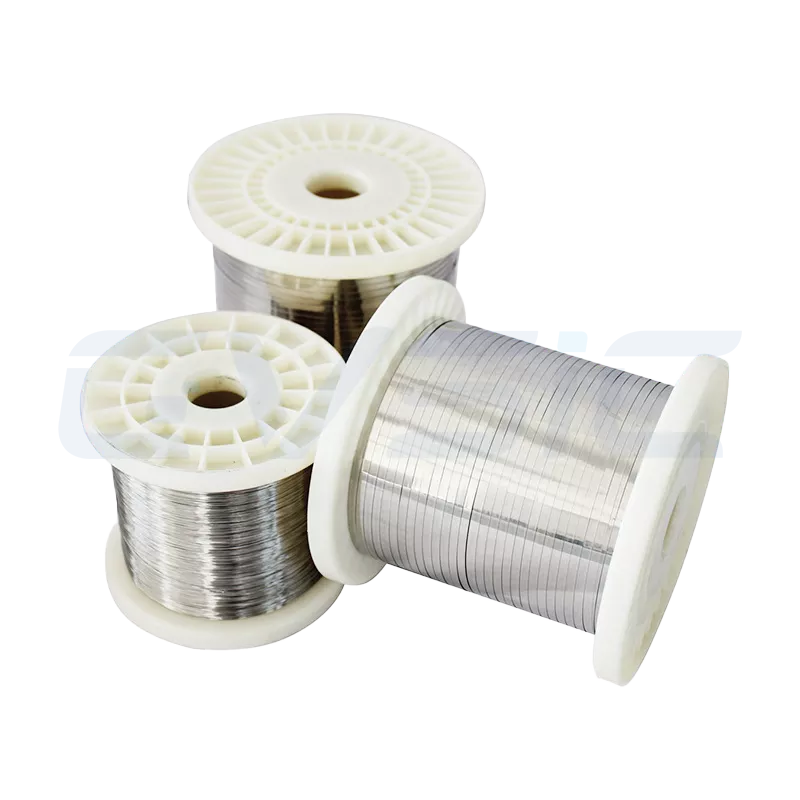

Resistance Wire

Resistance wire is an electric heating element that converts electrical energy into heat through the resistance of its metal. It’s widely used in industrial high-temperature heating, lab equipment, and home or commercial appliances.

Common materials for resistance wire include FeCrAl, NiCr, and NiCu—each with its own max temperature, oxidation resistance, and electrical properties.

It’s a popular choice because it handles high temperatures well, heats up quickly, is energy-efficient, lasts a long time, and can be customized easily.

Resistance Wire Manufacturer and Supplier In China

Resistance wire is a thin metal heating element that converts electrical energy into heat. It’s used to make a wide range of heating components, including wound coils, tubes, strips, and assemblies. In industrial heating systems, the reliability of these elements directly impacts temperature control, product quality, and energy use.

With predictable electrical behavior and flexible designs, resistance wire is a key part in both continuous and on-off heating setups.

Features of Resistance Heating Wire

- Handles high temperatures, perfect for ongoing industrial heating

- Precise temp control by tweaking resistance for stable processes

- Quick heat-up, stable resistivity, and even surface temperature

- Energy-efficient design that runs reliably at 600–1400°C for long periods

- Long-lasting even in oxidizing conditions

- Customizable in length, diameter, resistance, and power

- Straightforward power setup that works great with temp controllers

Features by Material

- FeCrAl (Iron-Chromium-Aluminum): Excellent high-temp and oxidation resistance

- NiCr (Nickel-Chromium): Stable resistance and strong mechanically

- NiCu (Nickel-Copper): Low resistance, great for precision heating

| Material System | Maximum Temperature | Key Features | Typical Applications |

|---|---|---|---|

| FeCrAl | ≈1400°C | High-temperature oxidation resistance, long service life | Industrial furnaces, ovens, electric heating tubes |

| NiCr | ≈1200°C | Stable temperature control, good mechanical strength | Ovens, laboratory furnaces, equipment heating |

| CuNi | <600°C | Stable resistance, suitable for precision heating | Instruments, current limiting, measurement equipment |

Buy High-Quality Resistance Wire from China

Quick Navigation

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

Cr20Ni80 Heating Wire

- Model: CV-Cr20Ni80

- Alloy Grade: Ni80Cr20

- Main Composition: Ni: Bal., Cr: 20–23, Fe: ≤1%

- Max Temp: 1200°C

- Resistivity (20°C): 1.09 μΩ·m

- Density: 8.4 g/cm³

- Forms Available: Diameters: 0.018–10mm; Strips: 0.02–2mm; Custom tolerances

- Common Uses: High-temp furnaces, lab gear, ceramic sintering, cutting wires, appliance heaters

Cr30Ni70 Heating Wire

- Model: CV-Cr30Ni70

- Alloy Grade: NiCr70/30

- Main Composition: Ni: Bal. (about 70%), Cr: 28–31%, Fe: ≤1.0%

- Max Temp: 1200°C

- Resistivity (20°C): 1.18 μΩ·m

- Density: 8.1 g/cm³

- Forms Available: Diameters: 0.02–10mm (round) Strips: 0.02–2mm Custom flat wire, rods, coils

- Common Uses: Industrial furnace wires – High-temp elements – Ceramic heaters – High-temp ovens/tunnel kilns – Mold heating, lab furnaces

Cr20Ni35 Heating Wire

- Model: CV-Cr20Ni35

- Alloy Grade: Nichrome 35/20

- Main Composition:Ni: Cr: ≈20%, Ni: ≈35%, Fe: Bal.

- Max Temp: 1100–1150°C

- Resistivity (20°C): 1.02 μΩ·m

- Density: 8.0 g/cm³

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Mid-high temp industrial furnaces, ovens, heating tubes, durable elements

Cr20Ni30 Alloy Heatin Wire

- Model: CV-Cr20Ni30

- Alloy Grade: Nichrome 70/30, Ni70Cr30

- Main Composition:Ni: Cr: 18–21%, Ni: 30–34%, Fe: Bal.

- Max Temp: 1100°C

- Resistivity (20°C): 1.04 μΩ·m

- Density: 7.9 g/cm³

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Heaters, electric tubes, hair dryer wires, damping/cutting wires (foam/plastic)

Cr15Ni60 Alloy Wire

- Model: CV-Cr15Ni60

- Alloy Grade: Nichrome 60/15

- Main Composition:Ni: 55–61%, Cr: 15–18%, Fe: Bal.

- Max Temp: 1100°C

- Resistivity (20°C): 1.12 μΩ·m

- Density: 8.2 g/cm³

- Forms Available: Wire, strip, flat; 0.03–8mm diameters; custom coiling

- Common Uses: Industrial furnaces, oven elements, heating tubes, mold heaters, durable wires

0Cr27Al7Mo2 Wire Kanthal APM Alternative

- Model: CV-0Cr27Al7Mo2

- Alloy Grade: Fe–Cr–Al–Mo high-temp resistance alloy

- Main Composition: Fe: Bal., Cr ≈27%, Al ≈7%, Mo (trace)

- Max Temp: ≤ 1400°C

- Resistivity (20°C): 1.50 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr21Al6Nb Resistance Wire Kanthal A1 Alternative

- Model: CV-0Cr21Al6Nb

- Alloy Grade: Fe–Cr–Al–Nb resistance alloy

- Main Composition: Fe: Bal., Cr ≈21%, Al ≈6%, Nb (trace)

- Max Temp: ≤ 1350°C

- Resistivity (20°C): 1.45 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr25Al5 Resistance Wire

- Model: CV-0Cr25Al5

- Alloy Grade: 0Cr25Al5 (FeCrAl 255)

- Main Composition: Fe: Bal.; Cr: 24–26; Al: 4.8–6.0; Mo: ≤0.5

- Max Temp: 1300°C

- Resistivity (20°C): 1.42 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

What CVSIC Offers in Resistance Wire

- Straight or coiled wire

- Spiral coils

- Flat ribbons

- Custom diameters (0.1–5 mm)

- Tailored resistivity and power density

- From small batches to full production runs

- Design helps to match resistance with your temp control setup.

We cover the full range of FeCrAl, NiCr, and CuNi materials.

Special options include surface-oxidized wire for extra oxidation protection.

Why Choose CVSIC?

Solve your problems with cvsic’s powerful capabilities

Production Capacity

Quality Control

Quick Support

Global Partnership

Applications of Resistance Heating Wire

- Industrial furnaces: Need stable resistance and oxidation resistance for round-the-clock operation.

- Heat treatment gear: Precise control and repeatable cycles are essential.

- Lab heaters: Small to large furnaces running 600-1100°C.

- Home appliances: Ovens, electric water heaters.

- Automated production lines: Compact and fast-response heating boosts efficiency and throughput.

- Coating and drying equipment

Comparison with Other Heating Elements

| Comparison Item | Heating Speed | Service Life | Energy Consumption/Efficiency | Safety | Customizability |

|---|---|---|---|---|---|

| Stainless Steel Wire | Medium | Medium | Medium | Medium | Low |

| Copper-Nickel Alloy Wire (CuNi) | Medium | Medium | Medium | High | Medium |

| Graphite Heating Element | High | High | Medium | Medium | Low |

| Ceramic Heating Element | High | Medium | Medium | Medium | Low |

| Carbon Fiber Heating Wire | High | Low | High | Medium | Medium |

| Resistance Wire (FeCrAl / NiCr / NiCu) | Fast | Long | High | High | High (customizable length, power, shape) |

Key Advantages

- Quick heating and long lifespan cut downtime costs.

- Highly customizable to fit unique power and space needs in industrial setups

- Efficient, oxidation- and corrosion-resistant for extended high-temp runs.

FAQ

How do I pick the right power and length?

It depends on your equipment, target temp, and heat-up speed. We’ll have an engineer work out a custom plan for you.

What’s the typical lifespan?

FeCrAl and NiCr can last 5,000–10,000 hours; NiCu a bit less. It varies with temperature and environment.

Max operating temperature?

Up to 1400°C for FeCrAl, 1200°C for NiCr, and NiCu for lower-temp apps.

How to avoid oxidation?

Go with surface oxidation treatment or use in inert gas; don’t run over temp for long periods.

Do you offer OEM or private-label services?

Yeah, we do. Services include coiling, drawing, oxidation treatment, resistivity tuning, and branding—perfect for global B2B and custom brands.

How does it stay oxidation-free at high temps?

A protective oxide layer, combined with the right alloy, keeps it stable in air for thousands of hours.

Why choose resistance wire over other heaters?

It beats stainless, CuNi, graphite, and ceramics in balancing high-temp stability, strength, and longevity—plus it’s easy to shape into coils or ribbons for all kinds of industrial uses.

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support