Optimise Your High-Temperature Industrial Processes

Selecting the right high-temperature heating element is crucial for enhancing process efficiency. Our team will help you choose or customise the ideal Silicon Carbide or Molybdenum Disilicide heating element to match your specific furnace and process requirements. Whether optimising existing systems or developing new equipment, our high-temperature ceramic heating elements provide stable, efficient heating performance to help you stay ahead in your industry.

Contact us to get your high-temperature heating element solution

Ready to elevate your high- and ultra-high-temperature processes with top-quality SiC or MoSi2 heaters? Contact us for quotes, product information, or custom solutions. We’re dedicated to fueling your success with world-class high-temperature furnace elements and professional service.

FAQ

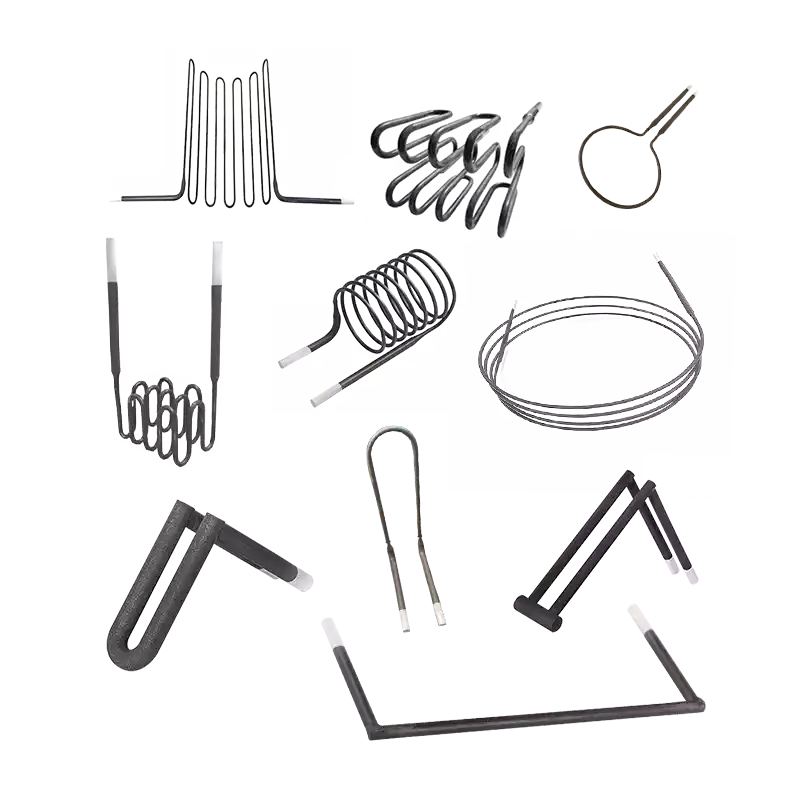

Do you offer custom SiC and MoSi2 heating element services?

Yes! We provide customized Silicon Carbide (SiC) and Molybdenum Disilicide (MoSi2) heating element services, designing custom SiC or MoSi2 rods (e.g., U-shaped, W-shaped, or unique configurations) based on your furnace dimensions, temperature requirements, and process needs. Share your specs with our team, and we’ll craft furnace elements tailored for you.

What is the lifespan of SiC and MoSi2 heating elements?

The lifespan of Silicon Carbide and Molybdenum Disilicide heating elements depends on operating temperature, environment, and maintenance. Our high-quality SiC rods resist corrosion and thermal shock, while MoSi2 rods excel in oxidation resistance, often lasting several years. Following our installation and maintenance guidelines can significantly extend the life of ceramic heating elements.

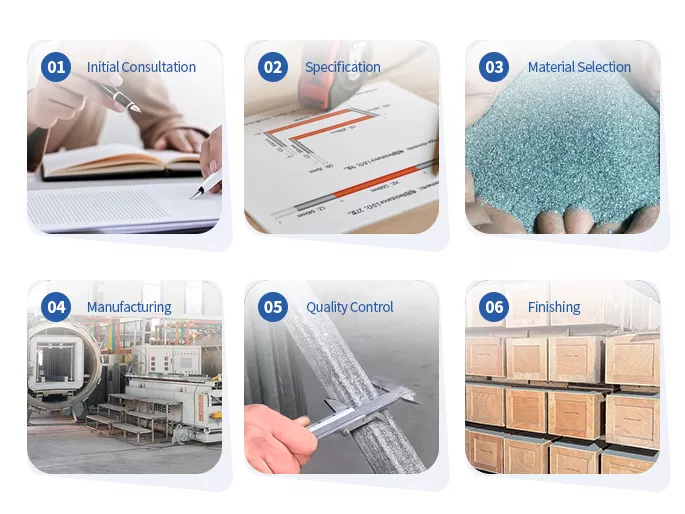

How do you ensure the quality of high-temperature heating elements?

Every SiC and MoSi2 heating element is made from high-purity materials and undergoes strict quality testing to meet international standards. Our cutting-edge manufacturing ensures consistent, durable performance for high-temperature furnace elements, and we provide guidance on selection, installation, and maintenance to optimize performance and longevity.

What are the prices for your SiC and MoSi2 heating elements? Do you support bulk purchases?

We offer competitive pricing for Silicon Carbide and Molybdenum Disilicide heating elements, with costs varying by model, specifications, and customization needs. We support bulk purchases and wholesale to cater to large-scale industrial needs. Reach out to our sales team for quotes and discounts.

Do you support global shipping? What’s the delivery time?

Yes, our global supply chain network ensures fast delivery of SiC and MoSi2 heaters to North America, Europe, Asia, and beyond. Standard furnace elements ship in 1–2 weeks; custom ones may take longer. Provide your order details, and we’ll confirm an accurate delivery timeline.

How do I choose the right high-temperature heating element for my application?

Choosing between SiC and MoSi2 heating elements depends on furnace size, operating temperature, power requirements, and process environment. Our technical team offers professional guidance to help you select the best high-temperature ceramic heating element. Share your application details, and we’ll recommend the optimal solution.